4. Software Implementation of the Gateway

4.2.8. Description of Services Assigned to Gateway Inputs/Outputs

Managing the downstream Modbus network: Please see chapter 5.2 Diagnostic only, page 37, for a detailed

description of this service. The example described in chapter 9.1 Main Program: “LAD 2 - MAIN_LUFP9”, page 86, only automatically acknowledges gateway diagnostics, that is to say it does not exploit the data from these diagnostics. In the case of the gateway’s default configuration, under AbcConf, the “Control/Status Byte” field of the “ABC” element is equal to “Enabled but no startup lock.”

Periodic communications (inputs): The value of each of the 8 words for this service corresponds to the value of the status register of a TeSys U motor starter (register located at address 455).

Periodic communications (outputs): The value of each of the 8 words for this service corresponds to the value to be sent to the command register for a TeSys U motor starter (register located at address 704).

Please see chapter 9.2 Controlling/Monitoring

Aperiodic communications: Please see chapter 9.3

Motor Starters: “LAD 4 - RD_PAR”, page 89, and chapter 9.4

TeSys U Motor Starter: “LAD 5 - WR_PAR”, page 91, for an example of how to use the “aperiodic communications” services.

These aperiodic communications services offer functions similar to those of “parameter area PKW”, which can be found on certain Schneider Electric products, such as some ATV drives.

The

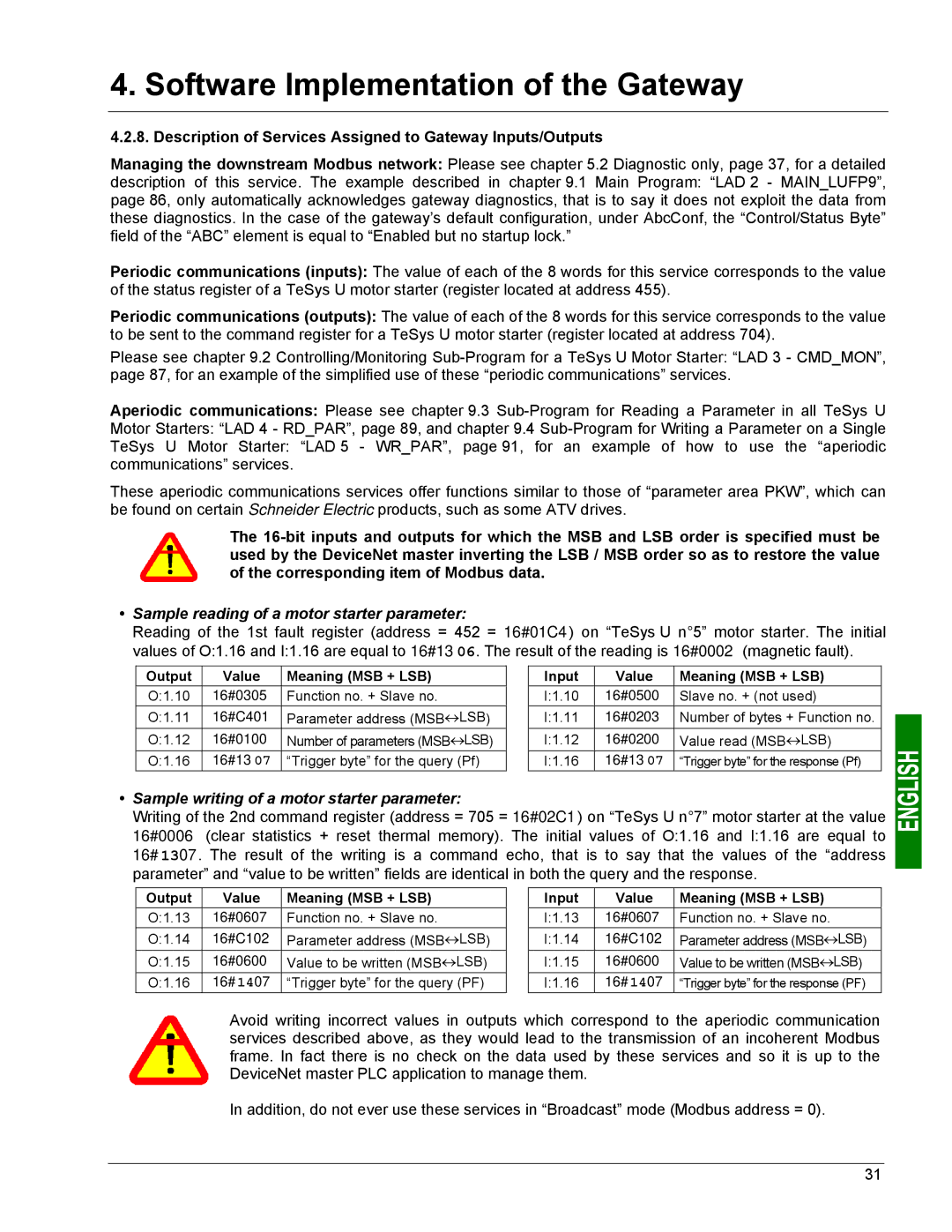

•Sample reading of a motor starter parameter:

Reading of the 1st fault register (address = 452 = 16#01C4) on “TeSys U n°5” motor starter. The initial values of O:1.16 and I:1.16 are equal to 16#1306. The result of the reading is 16#0002 (magnetic fault).

Output | Value | Meaning (MSB + LSB) |

O:1.10 | 16#0305 | Function no. + Slave no. |

O:1.11 | 16#C401 | Parameter address (MSB↔LSB) |

O:1.12 | 16#0100 | Number of parameters (MSB↔LSB) |

O:1.16 | 16#1307 | “Trigger byte” for the query (Pf) |

Input | Value | Meaning (MSB + LSB) |

I:1.10 | 16#0500 | Slave no. + (not used) |

I:1.11 | 16#0203 | Number of bytes + Function no. |

I:1.12 | 16#0200 | Value read (MSB↔LSB) |

I:1.16 | 16#1307 | “Trigger byte” for the response (Pf) |

•Sample writing of a motor starter parameter:

Writing of the 2nd command register (address = 705 = 16#02C1) on “TeSys U n°7” motor starter at the value 16#0006 (clear statistics + reset thermal memory). The initial values of O:1.16 and I:1.16 are equal to 16#1307. The result of the writing is a command echo, that is to say that the values of the “address parameter” and “value to be written” fields are identical in both the query and the response.

Output | Value | Meaning (MSB + LSB) |

O:1.13 | 16#0607 | Function no. + Slave no. |

O:1.14 | 16#C102 | Parameter address (MSB↔LSB) |

O:1.15 | 16#0600 | Value to be written (MSB↔LSB) |

O:1.16 | 16#1407 | “Trigger byte” for the query (PF) |

Input | Value | Meaning (MSB + LSB) |

I:1.13 | 16#0607 | Function no. + Slave no. |

I:1.14 | 16#C102 | Parameter address (MSB↔LSB) |

I:1.15 | 16#0600 | Value to be written (MSB↔LSB) |

I:1.16 | 16#1407 | “Trigger byte” for the response (PF) |

Avoid writing incorrect values in outputs which correspond to the aperiodic communication services described above, as they would lead to the transmission of an incoherent Modbus frame. In fact there is no check on the data used by these services and so it is up to the DeviceNet master PLC application to manage them.

In addition, do not ever use these services in “Broadcast” mode (Modbus address = 0).

31