Product Description

FORM

PRODUCT DESCRIPTION

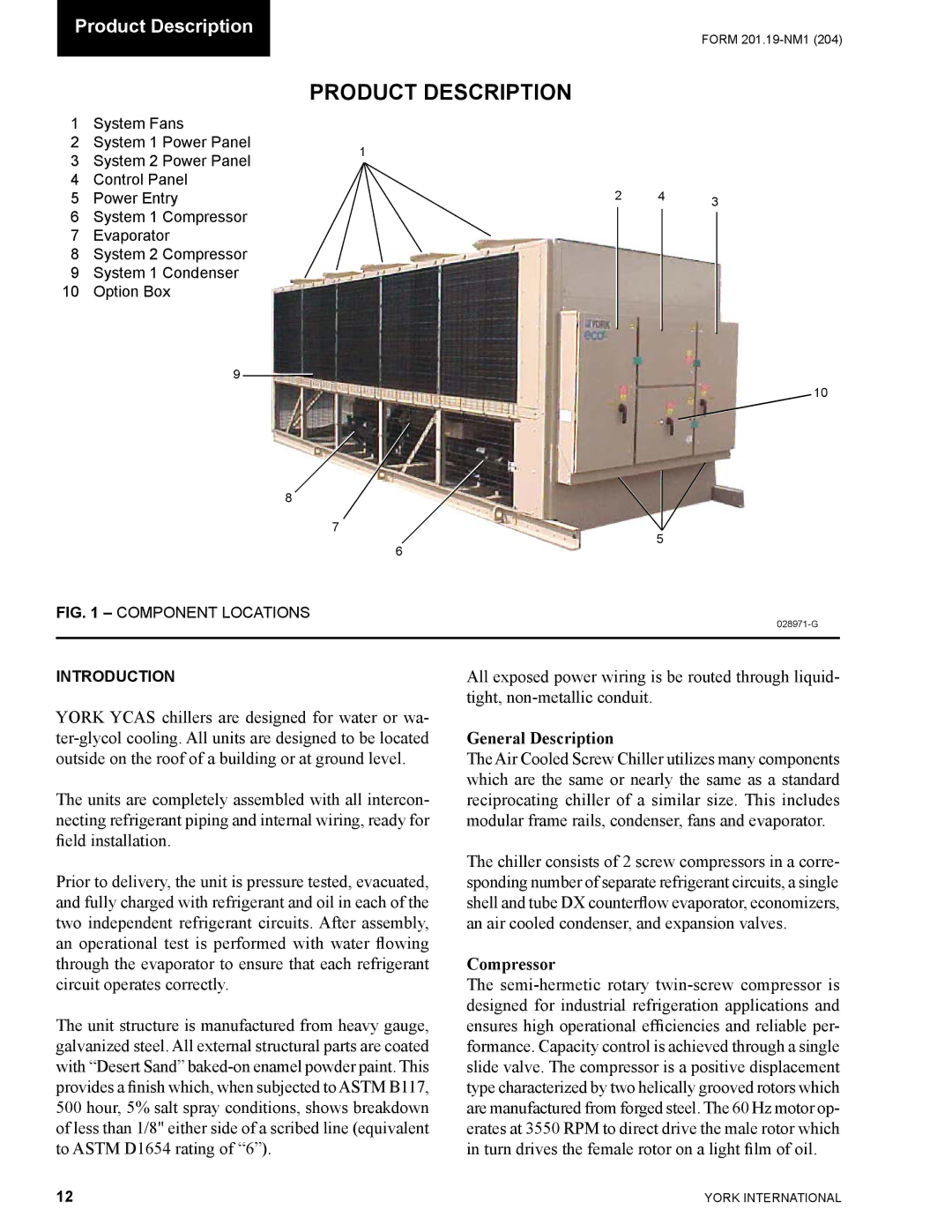

1 | System Fans |

|

|

|

2 | System 1 Power Panel | 1 |

|

|

3 | System 2 Power Panel |

|

| |

|

|

| ||

4 | Control Panel | 2 |

|

|

5 | Power Entry | 4 | 3 |

6System 1 Compressor

7Evaporator

8System 2 Compressor

9System 1 Condenser

10Option Box

9

10

8

7

5

6

FIG. 1 – COMPONENT LOCATIONS

INTRODUCTION

YORK YCAS chillers are designed for water or wa-

The units are completely assembled with all intercon- necting refrigerant piping and internal wiring, ready for field installation.

Prior to delivery, the unit is pressure tested, evacuated, and fully charged with refrigerant and oil in each of the two independent refrigerant circuits. After assembly, an operational test is performed with water flowing through the evaporator to ensure that each refrigerant circuit operates correctly.

The unit structure is manufactured from heavy gauge, galvanized steel. All external structural parts are coated with “Desert Sand”

All exposed power wiring is be routed through liquid- tight,

General Description

The Air Cooled Screw Chiller utilizes many components which are the same or nearly the same as a standard reciprocating chiller of a similar size. This includes modular frame rails, condenser, fans and evaporator.

The chiller consists of 2 screw compressors in a corre- sponding number of separate refrigerant circuits, a single shell and tube DX counterflow evaporator, economizers, an air cooled condenser, and expansion valves.

Compressor

The

12 | YORK INTERNATIONAL |