YORKINTERNATIONAL |

|

|

|

|

| |

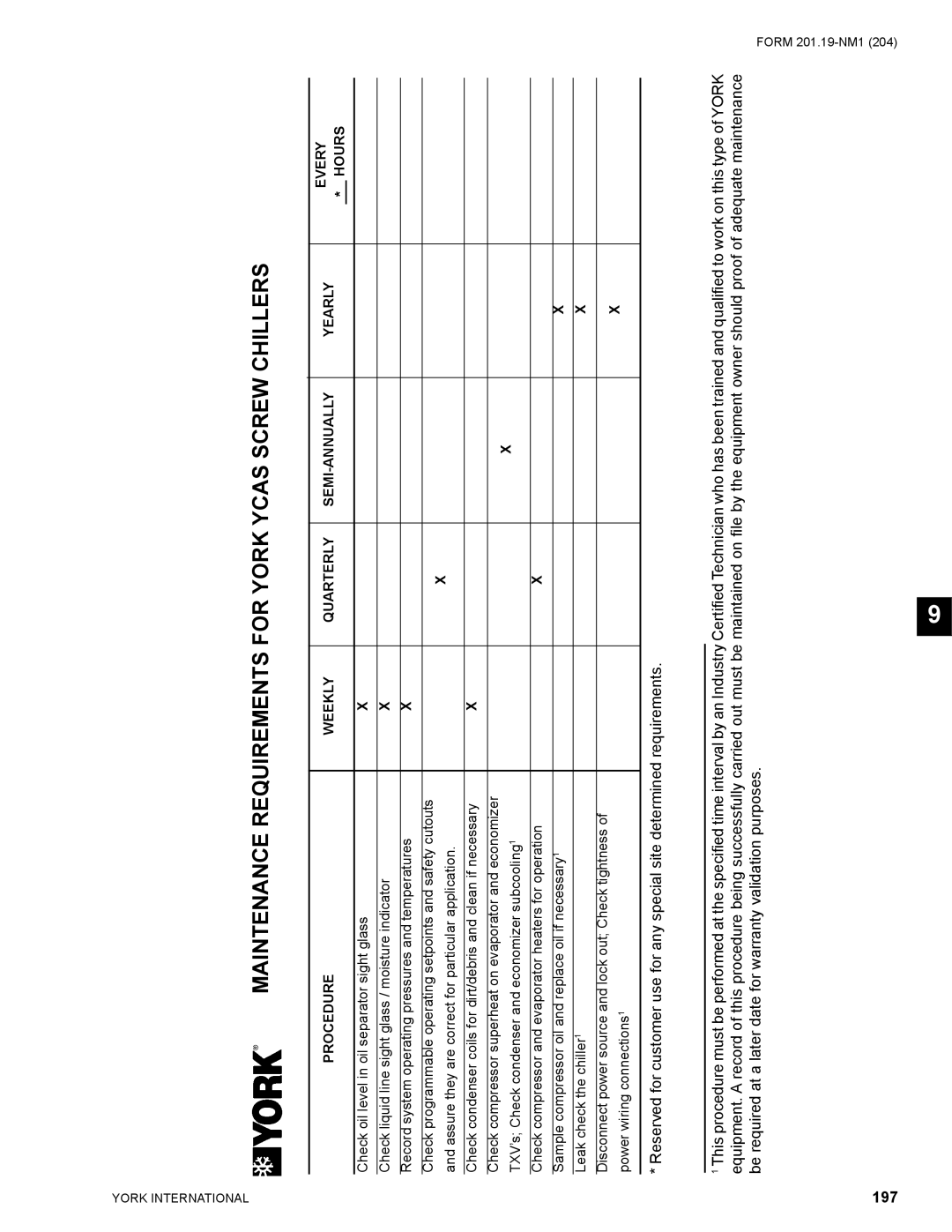

| MAINTENANCE REQUIREMENTS FOR YORK YCAS SCREW CHILLERS |

| ||||

|

|

|

|

|

|

|

| PROCEDURE | WEEKLY | QUARTERLY |

| YEARLY | EVERY |

| ___ | |||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

| Check oil level in oil separator sight glass | X |

|

|

|

|

| Check liquid line sight glass / moisture indicator | X |

|

|

|

|

| Record system operating pressures and temperatures | X |

|

|

|

|

| Check programmable operating setpoints and safety cutouts |

| X |

|

|

|

| and assure they are correct for particular application. |

|

|

|

| |

|

|

|

|

|

| |

| Check condenser coils for dirt/debris and clean if necessary | X |

|

|

|

|

| Check compressor superheat on evaporator and economizer |

|

| X |

|

|

| TXV’s; Check condenser and economizer subcooling1 |

|

|

|

| |

|

|

|

|

|

| |

| Check compressor and evaporator heaters for operation |

| X |

| X |

|

| Sample compressor oil and replace oil if necessary1 |

|

|

|

| |

| Leak check the chiller1 |

|

|

| X |

|

| Disconnect power source and lock out; Check tightness of |

|

|

| X |

|

| power wiring connections1 |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

* Reserved for customer use for any special site determined requirements.

1This procedure must be performed at the specified time interval by an Industry Certified Technician who has been trained and qualified to work on this type of YORK equipment. A record of this procedure being successfully carried out must be maintained on file by the equipment owner should proof of adequate maintenance be required at a later date for warranty validation purposes.

197

9

*

FORM