cooling mode, the saturated suction temperature unload point is 24ºF

Temperature Difference | Maximum Steps of | |

Between Saturated Suc- | ||

Loading After Load | ||

tion Temperature and the | ||

Timer Counts to "0" | ||

Unload Temperature | ||

| ||

< 7.0 | 3 | |

< 4.5 | 2 | |

< 2.5 | 1 | |

< 1.0 | 0 |

ANTICIPATORY UNLOADING CONTROLS

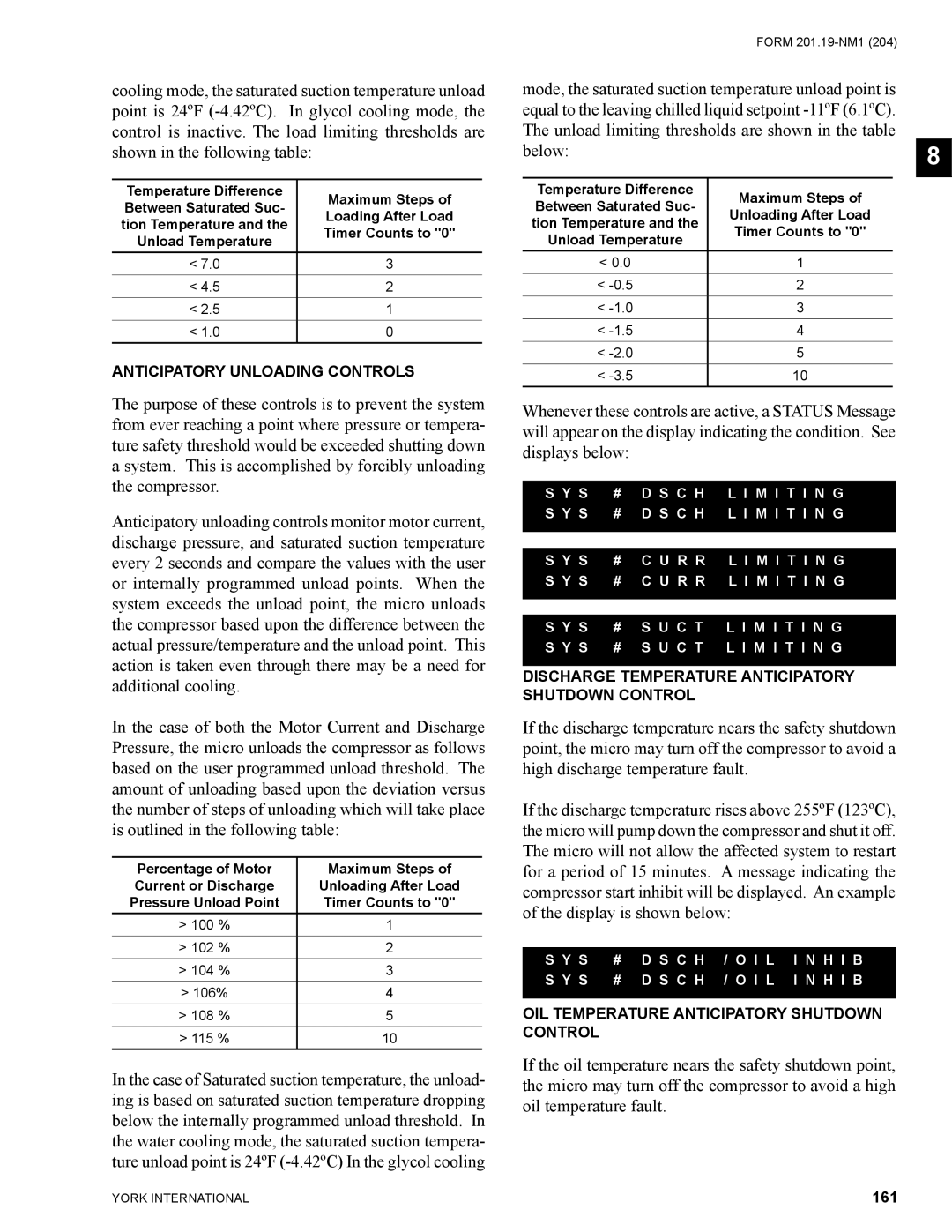

The purpose of these controls is to prevent the system from ever reaching a point where pressure or tempera- ture safety threshold would be exceeded shutting down a system. This is accomplished by forcibly unloading the compressor.

Anticipatory unloading controls monitor motor current, discharge pressure, and saturated suction temperature every 2 seconds and compare the values with the user or internally programmed unload points. When the system exceeds the unload point, the micro unloads the compressor based upon the difference between the actual pressure/temperature and the unload point. This action is taken even through there may be a need for additional cooling.

In the case of both the Motor Current and Discharge Pressure, the micro unloads the compressor as follows based on the user programmed unload threshold. The amount of unloading based upon the deviation versus the number of steps of unloading which will take place is outlined in the following table:

Percentage of Motor | Maximum Steps of |

Current or Discharge | Unloading After Load |

Pressure Unload Point | Timer Counts to "0" |

> 100 % | 1 |

> 102 % | 2 |

> 104 % | 3 |

> 106% | 4 |

> 108 % | 5 |

> 115 % | 10 |

In the case of Saturated suction temperature, the unload- ing is based on saturated suction temperature dropping below the internally programmed unload threshold. In the water cooling mode, the saturated suction tempera- ture unload point is 24ºF

FORM

mode, the saturated suction temperature unload point is equal to the leaving chilled liquid setpoint

Temperature Difference | Maximum Steps of | |

Between Saturated Suc- | ||

Unloading After Load | ||

tion Temperature and the | ||

Timer Counts to "0" | ||

Unload Temperature | ||

| ||

< 0.0 | 1 | |

< | 2 | |

< | 3 | |

< | 4 | |

< | 5 | |

< | 10 |

Whenever these controls are active, a STATUS Message will appear on the display indicating the condition. See displays below:

S Y S # D S C H L I M I T I N G S Y S # D S C H L I M I T I N G

S Y S # C U R R L I M I T I N G S Y S # C U R R L I M I T I N G

S Y S # S U C T L I M I T I N G S Y S # S U C T L I M I T I N G

DISCHARGE TEMPERATURE ANTICIPATORY SHUTDOWN CONTROL

If the discharge temperature nears the safety shutdown point, the micro may turn off the compressor to avoid a high discharge temperature fault.

If the discharge temperature rises above 255ºF (123ºC), the micro will pump down the compressor and shut it off. The micro will not allow the affected system to restart for a period of 15 minutes. A message indicating the compressor start inhibit will be displayed. An example of the display is shown below:

S Y S | # | D S C H | / O I L | I N H I B |

S Y S | # | D S C H | / O I L | I N H I B |

|

|

|

|

|

OIL TEMPERATURE ANTICIPATORY SHUTDOWN CONTROL

If the oil temperature nears the safety shutdown point, the micro may turn off the compressor to avoid a high oil temperature fault.

8

YORK INTERNATIONAL | 161 |