Troubleshooting

FORM

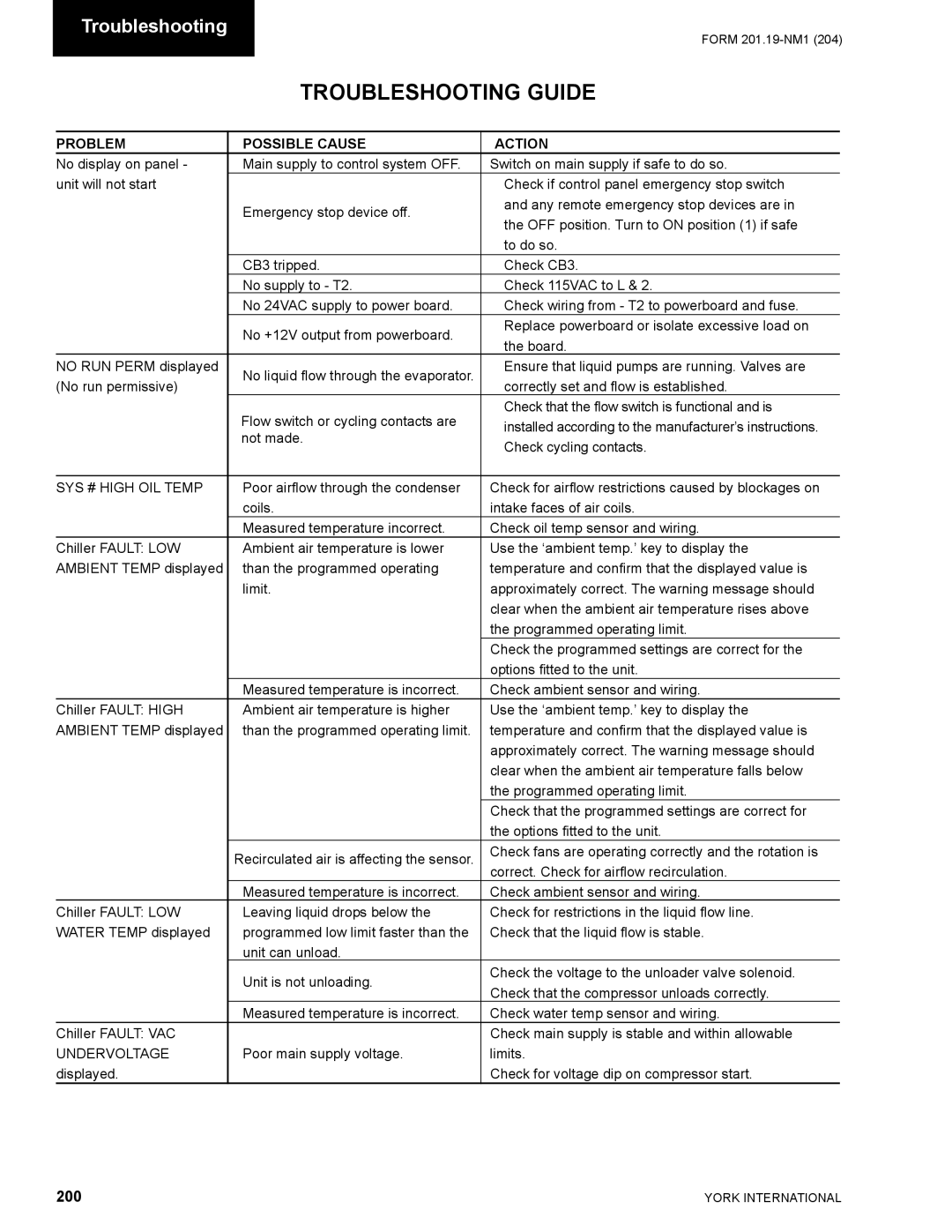

TROUBLESHOOTING GUIDE

PROBLEM |

| POSSIBLE CAUSE | ACTION POSSIBLE CAUSE | ACTION | |

No display on panel - |

| Main supply to control system OFF. | Switch on main supply if safe to do so. |

| |

unit will not start |

|

|

| Check if control panel emergency stop switch | |

|

| Emergency stop device off. | and any remote emergency stop devices are in | ||

|

| the OFF position. Turn to ON position (1) if safe | |||

|

|

|

| ||

|

|

|

| to do so. |

|

|

| CB3 tripped. | Check CB3. |

| |

|

| No supply to - T2. | Check 115VAC to L & 2. |

| |

|

| No 24VAC supply to power board. | Check wiring from - T2 to powerboard and fuse. | ||

|

| No +12V output from powerboard. | Replace powerboard or isolate excessive load on | ||

|

| the board. |

| ||

|

|

|

|

| |

NO RUN PERM displayed |

| No liquid flow through the evaporator. | Ensure that liquid pumps are running. Valves are | ||

(No run permissive) |

| correctly set and flow is established. |

| ||

|

|

|

| ||

|

|

|

| Check that the flow switch is functional and is | |

|

| Flow switch or cycling contacts are |

| ||

|

|

| installed according to the manufacturer’s instructions. | ||

|

| Flow switch contacts are not made. |

| ||

|

| not made. |

| Check cycling contacts. |

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

SYS # HIGH OIL TEMP |

| Poor airflow through the condenser | Check for airflow restrictions caused by blockages on | ||

|

| coils. | intake faces of air coils. |

| |

|

| Measured temperature incorrect. | Check oil temp sensor and wiring. |

| |

Chiller FAULT: LOW |

| Ambient air temperature is lower | Use the ‘ambient temp.’ key to display the | ||

AMBIENT TEMP displayed |

| than the programmed operating | temperature and confirm that the displayed value is | ||

|

| limit. | approximately correct. The warning message should | ||

|

|

|

| clear when the ambient air temperature rises above | |

|

|

|

| the programmed operating limit. |

|

|

|

|

| Check the programmed settings are correct for the | |

|

|

|

| options fitted to the unit. |

|

|

| Measured temperature is incorrect. | Check ambient sensor and wiring. |

| |

Chiller FAULT: HIGH |

| Ambient air temperature is higher | Use the ‘ambient temp.’ key to display the | ||

AMBIENT TEMP displayed |

| than the programmed operating limit. | temperature and confirm that the displayed value is | ||

|

|

|

| approximately correct. The warning message should | |

|

|

|

| clear when the ambient air temperature falls below | |

|

|

|

| the programmed operating limit. |

|

|

|

|

| Check that the programmed settings are correct for | |

|

|

|

| the options fitted to the unit. |

|

|

| RecirculatedResid. heat airis notis affectingbeing dissipatedthe sensor. . | Check fans are operating correctly and the rotation is | ||

|

| correct. Check for airflow recirculation. |

| ||

|

|

|

|

| |

|

| Measured temperature is incorrect. | Check ambient sensor and wiring. |

| |

Chiller FAULT: LOW |

| Leaving liquid drops below the | Check for restrictions in the liquid flow line. | ||

WATER TEMP displayed |

| programmed low limit faster than the | Check that the liquid flow is stable. |

| |

|

| unit can unload. |

|

| |

|

| Unit is not unloading. | Check the voltage to the unloader valve solenoid. | ||

|

| Check that the compressor unloads correctly. | |||

|

|

|

| ||

|

| Measured temperature is incorrect. | Check water temp sensor and wiring. |

| |

Chiller FAULT: VAC |

|

|

| Check main supply is stable and within allowable | |

UNDERVOLTAGE |

| Poor main supply voltage. | limits. |

| |

displayed. |

|

|

| Check for voltage dip on compressor start. | |

200 | YORK INTERNATIONAL |