Micro Panel Contents

FORM

Whenever chilled liquid leaving temperature is above the Setpoint plus the control range, loading voltage will increase to allow oil pressure to push against the internal slide valve return spring and move the slide valve to increase capacity. Every 10 seconds, when the load timer decrements to 0, the micro will increment the slide valve step from 1 to 10 steps according to error (deviation from setpoint) and rate of change of chilled liquid.

The micro will always choose the compressor with the lowest slide valve position to load on increasing demand, provided the compressor is not pumping down, has run at least 15 seconds, and is not in a “Limiting” condition.

Compressor Unloading and Shutdown Sequence Whenever temperature is below the Setpoint, minus the control range, the voltage to the slide valve solenoid will decrease, which bypasses oil pressure to the slide valve allowing the slide valve return spring to move the slide valve forward to the fully unloaded position on the compressor with highest slide valve step. Every 5 sec- onds, the micro will decrement the compressor with the highest slide valve position by 1 - 10 steps according to the error (deviation from Setpoint) and the rate of change of chilled liquid temperature until the temperature falls within the control range.

As load drops, the micro will continue to unload the compressor with the highest slide valve step until all compressor slide valves are at “0.” At this point, the last lag compressor will pump down and cycle off, if chilled liquid temperature drops below “Setpoint - Con- trol Range/2”. When the lag compressor cycles off, the lead compressor slide valve will increment to step

30.As load continues to decrease, the lead compressor will continue to unload to a slide valve position of “0” and will pump down and cycle off if the chilled liquid temperature drops below “Setpoint – Control Range.”

The lag compressor may be shut down before it is fully unloaded to avoid a Chiller fault on a Low Water Tem- perature

The lead compressor may be shut down before it is fully unloaded to avoid a Chiller Fault on Low Water Tempera- ture under the following conditions:

a)if chilled liquid temperature drops 2°F below the low limit of the Control Range (CR), b) if chilled liquid tem- perature drops more than CR/2 below the low limit of the Control Range.

ANTICIPATORY LOAD LIMITING CONTROLS

The purpose of the Anticipatory Load Limiting controls is to prevent the system from ever reaching a point where the micro would be forced to unload a system to prevent the system from reaching a safety threshold. This in turn prevents cycling of the slide valve as the micro would load and unload the system as system operating pressures and temperatures move above and below the forced unload point.

Anticipatory load limiting controls monitor motor cur- rent, discharge pressure, and saturated suction tempera- ture. When the system is called to load in an attempt to satisfy chilled liquid temperature, the micro looks at these three operating parameters and determines if any are nearing the user programmed or internal micropro- cessor unload threshold points programmed into the micro panel. If the micro determines that the unload points could be exceeded, it limits the steps of loading or may decide not to provide any further loading of the specific system, even though there is a need for addi- tional cooling. No status display will be present when anticipatory load limiting occurs.

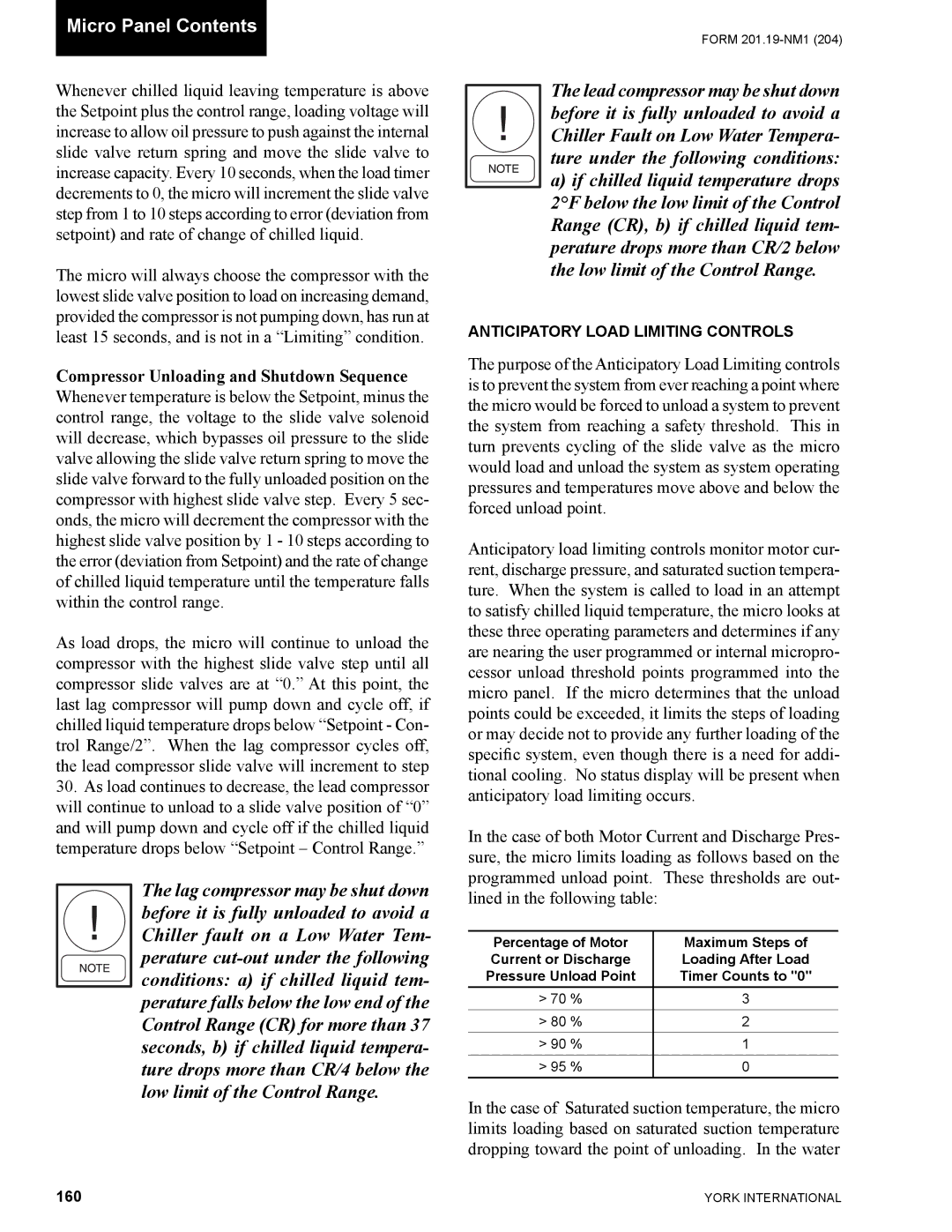

In the case of both Motor Current and Discharge Pres- sure, the micro limits loading as follows based on the programmed unload point. These thresholds are out- lined in the following table:

Percentage of Motor | Maximum Steps of |

Current or Discharge | Loading After Load |

Pressure Unload Point | Timer Counts to "0" |

> 70 % | 3 |

> 80 % | 2 |

> 90 % | 1 |

> 95 % | 0 |

In the case of Saturated suction temperature, the micro limits loading based on saturated suction temperature dropping toward the point of unloading. In the water

160 | YORK INTERNATIONAL |