to the Setpoint Temperature. The amount of loading is varied by changing the amount of DC Voltage signal to the slide valve solenoid of each compressor. Voltage increases with load (0 - approximately 9VDC at full load).

Slide Valve Control

The slide valve of each compressor can be moved 75 steps, where “0” equals minimum capacity and fully loaded equals 75 steps. The amount of movement that occurs when the micro initiates changes may vary ac- cording to the error or deviation from setpoint and the rate of change of chilled liquid temperature. Each time a change is made, the incremental change may vary from 1 to 10 steps as determined from the micro. In cases where internal limiting is not in effect due to possible fault conditions, the micro will load the compressor with the lowest number of steps, alternating loading back and forth between compressors until both are fully loaded.

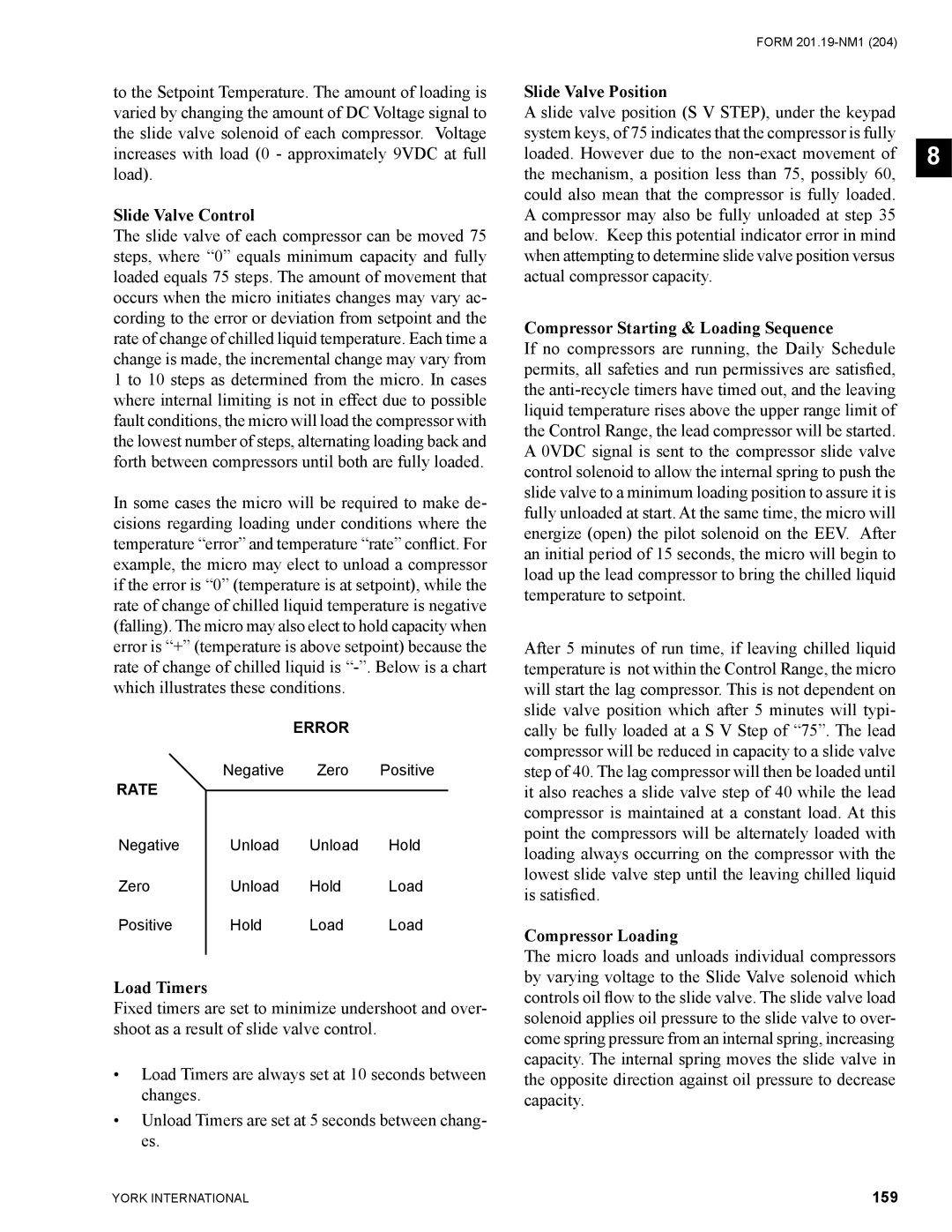

In some cases the micro will be required to make de- cisions regarding loading under conditions where the temperature “error” and temperature “rate” conflict. For example, the micro may elect to unload a compressor if the error is “0” (temperature is at setpoint), while the rate of change of chilled liquid temperature is negative (falling). The micro may also elect to hold capacity when error is “+” (temperature is above setpoint) because the rate of change of chilled liquid is

|

| ERROR |

|

RATE | Negative | Zero | Positive |

|

|

| |

Negative | Unload | Unload | Hold |

Zero | Unload | Hold | Load |

Positive | Hold | Load | Load |

Load Timers

Fixed timers are set to minimize undershoot and over- shoot as a result of slide valve control.

•Load Timers are always set at 10 seconds between changes.

•Unload Timers are set at 5 seconds between chang- es.

FORM

Slide Valve Position

A slide valve position (S V STEP), under the keypad system keys, of 75 indicates that the compressor is fully loaded. However due to the

Compressor Starting & Loading Sequence

If no compressors are running, the Daily Schedule permits, all safeties and run permissives are satisfied, the

After 5 minutes of run time, if leaving chilled liquid temperature is not within the Control Range, the micro will start the lag compressor. This is not dependent on slide valve position which after 5 minutes will typi- cally be fully loaded at a S V Step of “75”. The lead compressor will be reduced in capacity to a slide valve step of 40. The lag compressor will then be loaded until it also reaches a slide valve step of 40 while the lead compressor is maintained at a constant load. At this point the compressors will be alternately loaded with loading always occurring on the compressor with the lowest slide valve step until the leaving chilled liquid is satisfied.

Compressor Loading

The micro loads and unloads individual compressors by varying voltage to the Slide Valve solenoid which controls oil flow to the slide valve. The slide valve load solenoid applies oil pressure to the slide valve to over- come spring pressure from an internal spring, increasing capacity. The internal spring moves the slide valve in the opposite direction against oil pressure to decrease capacity.

8

YORK INTERNATIONAL | 159 |