Low Oil Differential Pressure Cutout:

S Y S | # | L O W | O I | L | D | I | F F |

S Y S | # | L O W | O I | L | D | I | F F |

|

|

|

|

|

|

|

|

The Low Oil Pressure Differential Safety assures the compressor receives proper lubrication by monitoring the differential between oil pressure returning to the compressor and suction pressure. Lack of a differential indicates that the compressor is not pumping and no oil is being pumped through the compressor to lubricate the bearings and rotors.

This type of oil failure will not be picked up by the High Oil Differential Safety since no flow will cause the dif- ferential through the oil piping to drop to zero.

During normal operation, differential oil pressure must be greater than 50 PSID. At

For ambients above 50°F (10°C), the Low Oil Differ- ential Safety is activated after 1 minute of compressor operation when the oil pressure differential must be greater than 10 PSID (.7 bar). After 2 minutes it must be greater than 20 PSID (1.4 bar); after 3 minutes, 30 PSID (2 bar); after 4 minutes, 40 PSID (2.7 bar); and from 5 minutes of operation and onwards, oil pressure must remain higher than 50 PSID (3.4 bar) or the system will be shut down. For lower ambients, the linear ramp times are as follows:

AMBIENT TEMP | RAMP TIME |

| ||

>50°F | (10°C) | 5 | Minutes |

|

>45°F | (7°C) | 6 | Minutes |

|

>40°F | (4°C) | 7 | Minutes |

|

>35°F | (2°C) | 8 | Minutes | |

>30°F | 9 | Minutes |

| |

<=30°F | 10 | Minutes | ||

High Oil Temperature Cutout:

S Y S | # | H | I G H | O I | L | T E M P |

S Y S | # | H | I G H | O I | L | T E M P |

|

|

|

|

|

|

|

This safety assures oil temperature does not exceed a safe operating temperature which affects compressor lubrica- tion. Typical oil temperature during normal operation will be approximately 130 - 150°F (54 - 66°C).

The High Oil Temperature Safety is activated after 2 minutes of compressor operation, after which if oil temperature is above 225°F (107°C) for more than 3 seconds, the compressor will shut down.

FORM

Low Suction Pressure Cutout:

|

| S Y S | # | L O W | S U C T | P R E S S |

|

|

|

| S Y S | # | L O W | S U C T | P R E S S |

|

|

|

|

| 8 | |||||

|

|

| ||||||

|

|

|

| |||||

| The Low Suction Pressure Cutout aids in protecting the | |||||||

|

| |||||||

evaporator from damage due to ice build up caused by operation at low refrigerant charge or restricted refrig- erant flow. A transient timer feature prevents nuisance trips during

8.2/ Page 167, Low Suction Pressure Cutout for more details).

The suction pressure

SP Cutout= Programmed Cutout X (run Time - 25)

200

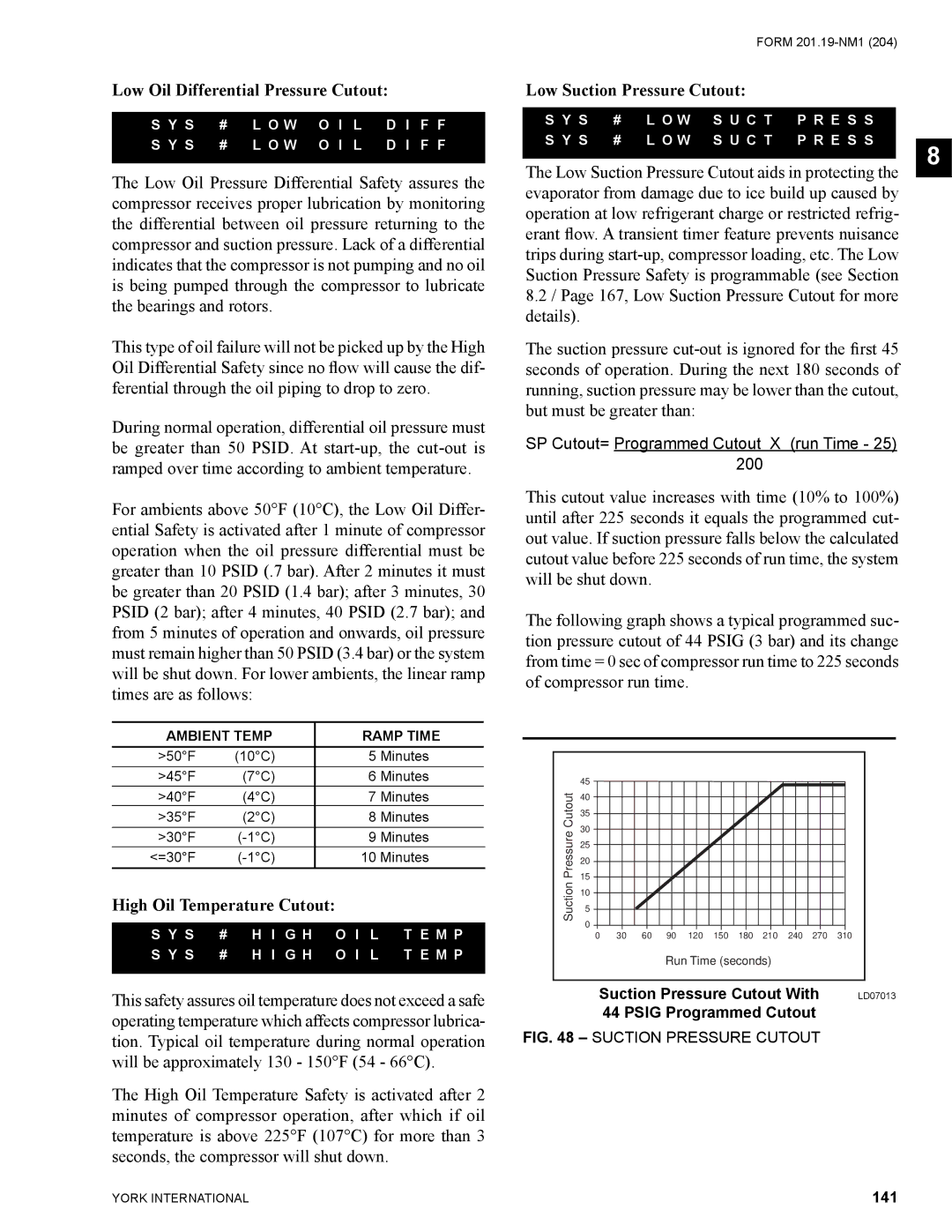

This cutout value increases with time (10% to 100%) until after 225 seconds it equals the programmed cut- out value. If suction pressure falls below the calculated cutout value before 225 seconds of run time, the system will be shut down.

The following graph shows a typical programmed suc- tion pressure cutout of 44 PSIG (3 bar) and its change from time = 0 sec of compressor run time to 225 seconds of compressor run time.

| 45 |

|

|

|

|

|

|

|

|

|

|

Cutout | 40 |

|

|

|

|

|

|

|

|

|

|

35 |

|

|

|

|

|

|

|

|

|

| |

30 |

|

|

|

|

|

|

|

|

|

| |

Pressure |

|

|

|

|

|

|

|

|

|

| |

25 |

|

|

|

|

|

|

|

|

|

| |

20 |

|

|

|

|

|

|

|

|

|

| |

15 |

|

|

|

|

|

|

|

|

|

| |

Suction |

|

|

|

|

|

|

|

|

|

| |

10 |

|

|

|

|

|

|

|

|

|

| |

5 |

|

|

|

|

|

|

|

|

|

| |

0 |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

| 0 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 310 |

|

|

|

| Run Time (seconds) |

|

|

| ||||

Suction Pressure Cutout With | LD07013 |

44 PSIG Programmed Cutout |

|

FIG. 48 – SUCTION PRESSURE CUTOUT

YORK INTERNATIONAL | 141 |