Micro Panel Contents

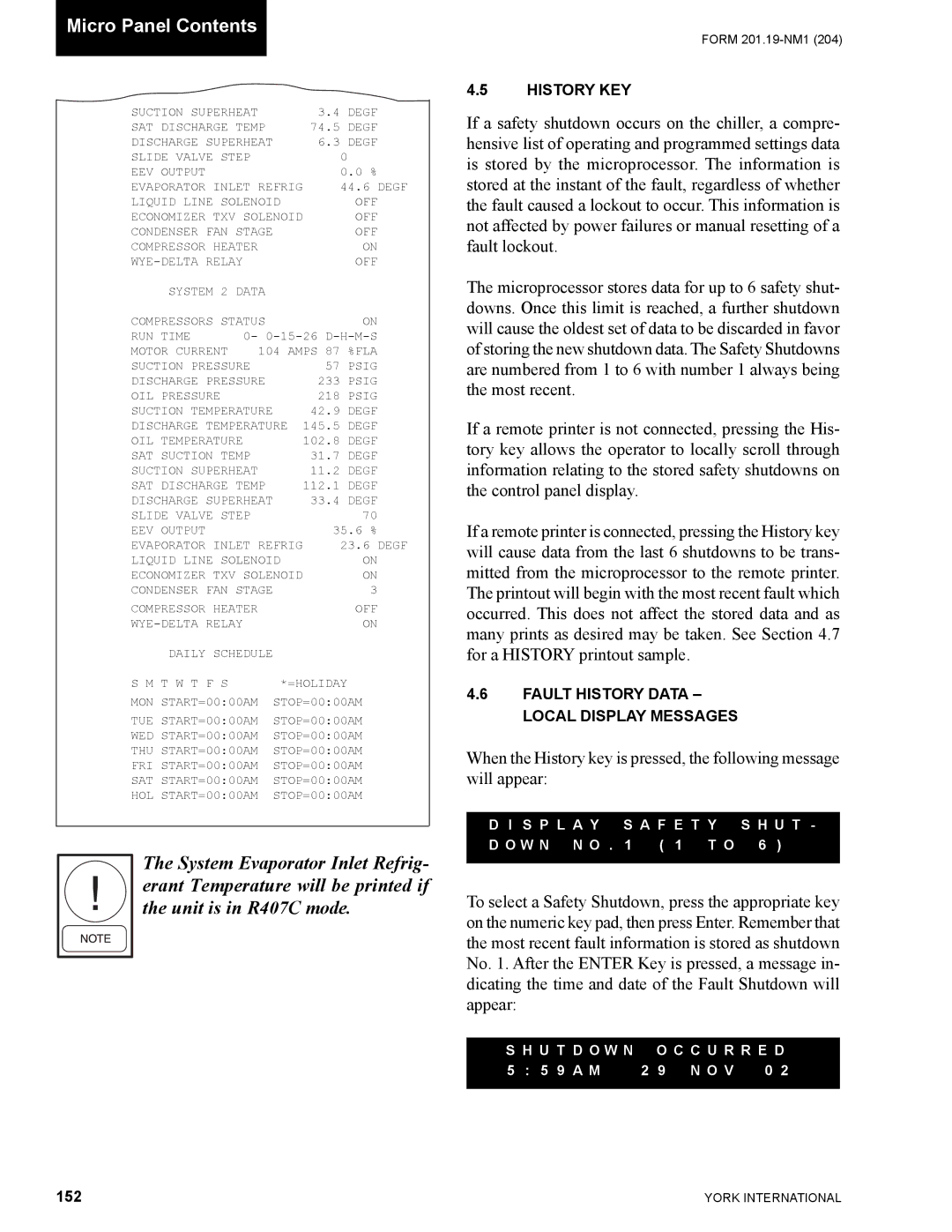

SUCTION SUPERHEAT | 3.4 | DEGF | |

SAT DISCHARGE TEMP | 74.5 | DEGF | |

DISCHARGE SUPERHEAT | 6.3 | DEGF | |

SLIDE VALVE STEP |

| 0 | |

EEV OUTPUT |

|

| 0.0 % |

EVAPORATOR INLET REFRIG | 44.6 DEGF | ||

LIQUID LINE SOLENOID | OFF | ||

ECONOMIZER TXV SOLENOID | OFF | ||

CONDENSER FAN STAGE |

| OFF | |

COMPRESSOR HEATER |

| ON | |

|

| OFF | |

SYSTEM 2 DATA |

|

| |

COMPRESSORS STATUS |

| ON | |

RUN TIME | 0- | ||

MOTOR CURRENT | 104 AMPS 87 %FLA | ||

SUCTION PRESSURE | 57 | PSIG | |

DISCHARGE PRESSURE | 233 | PSIG | |

OIL PRESSURE |

| 218 | PSIG |

SUCTION TEMPERATURE | 42.9 | DEGF | |

DISCHARGE TEMPERATURE 145.5 DEGF | |||

OIL TEMPERATURE |

| 102.8 | DEGF |

SAT SUCTION TEMP | 31.7 | DEGF | |

SUCTION SUPERHEAT | 11.2 | DEGF | |

SAT DISCHARGE TEMP | 112.1 | DEGF | |

DISCHARGE SUPERHEAT | 33.4 | DEGF | |

SLIDE VALVE STEP |

| 70 | |

EEV OUTPUT |

| 35.6 % | |

EVAPORATOR INLET REFRIG | 23.6 DEGF | ||

LIQUID LINE SOLENOID | ON | ||

ECONOMIZER TXV SOLENOID | ON | ||

CONDENSER FAN STAGE |

| 3 | |

COMPRESSOR HEATER |

| OFF | |

|

| ON | |

DAILY SCHEDULE |

|

| |

S M T W T F S |

| *=HOLIDAY | |

MON START=00:00AM | STOP=00:00AM | ||

TUE START=00:00AM | STOP=00:00AM | ||

WED START=00:00AM | STOP=00:00AM | ||

THU START=00:00AM | STOP=00:00AM | ||

FRI START=00:00AM | STOP=00:00AM | ||

SAT START=00:00AM | STOP=00:00AM | ||

HOL START=00:00AM | STOP=00:00AM | ||

The System Evaporator Inlet Refrig- erant Temperature will be printed if the unit is in R407C mode.

FORM

4.5HISTORY KEY

If a safety shutdown occurs on the chiller, a compre- hensive list of operating and programmed settings data is stored by the microprocessor. The information is stored at the instant of the fault, regardless of whether the fault caused a lockout to occur. This information is not affected by power failures or manual resetting of a fault lockout.

The microprocessor stores data for up to 6 safety shut- downs. Once this limit is reached, a further shutdown will cause the oldest set of data to be discarded in favor of storing the new shutdown data. The Safety Shutdowns are numbered from 1 to 6 with number 1 always being the most recent.

If a remote printer is not connected, pressing the His- tory key allows the operator to locally scroll through information relating to the stored safety shutdowns on the control panel display.

If a remote printer is connected, pressing the History key will cause data from the last 6 shutdowns to be trans- mitted from the microprocessor to the remote printer. The printout will begin with the most recent fault which occurred. This does not affect the stored data and as many prints as desired may be taken. See Section 4.7 for a HISTORY printout sample.

4.6FAULT HISTORY DATA – LOCAL DISPLAY MESSAGES

When the History key is pressed, the following message will appear:

D I S P L A Y S A F E T Y S H U T - D O W N N O . 1 ( 1 T O 6 )

To select a Safety Shutdown, press the appropriate key on the numeric key pad, then press Enter. Remember that the most recent fault information is stored as shutdown No. 1. After the ENTER Key is pressed, a message in- dicating the time and date of the Fault Shutdown will appear:

S H U T D O W N O C C U R R E D

5 : 5 9 A M | 2 9 N O V 0 2 |

152 | YORK INTERNATIONAL |