Hp LaserJet Service5100tn 5100dtn 5100Le

Page

Service

Copyright Hewlett -Packard Company

Contents

Printer operation

Q1860-90918

Functional information

Removing and replacing parts

Troubleshooting

Q1860-90918

Figures

Tray 1 inner cover removal 2 of 2, front of printer

Sheet feeder feed roller removal 178

275

Tables

251

Printer description

Overview

Printer features

Printer features

HP LaserJet 5100tn printer

Printer information

HP LaserJet 5100 printer

HP LaserJet 5100dtn printer

Q1860A Q1861A Q1862A Q1863A

Identification

Model and serial numbers

Environmental and power requirements

Site requirements

Space requirements

139.8 cm 55 62.5 cm 24.6

Printer weight without toner cartridge

Environmental specifications Operating Storage

Environmental requirements

Paper specifications

Paper specifications, duplexer Dimensions Weight

Supported types of paper

Guidelines for using paper

Media issues Symptom Problem with paper Solution

Paper weight equivalence table

Vellum

Labels

Transparencies

Envelopes

Envelope margins

Envelopes that have double side seams

Envelopes that have adhesive strips or flaps

Envelope storage

Card stock and heavy paper

Card stock construction

Card stock guidelines

Canadian DOC regulations

Safety information

Laser safety statement

FCC regulations

Material Safety Data Sheet

Laser statement for Finland Luokan 1 laserlaite

This HP LaserJet printer design reduces

Environmental product stewardship

Protecting the environment

Printer design eliminates

Service approach

Limited warranty for the print cartridge

Service approach

Warranty

Regulatory information

Service and support

Worldwide service and support offices

Europe

Asia-Pacific countries/regions

Service approach Q1860-90918

Printer operation

Control panel lights

Using the control panel

Control panel layout

Interpreting control panel lights

Control panel keys

Control panel keys Key Function

Settings and defaults

Settings and defaults

Setting the display language

Setting or default Explanation

To change a control panel setting

Control panel menus

To print a control panel menu map

Jobname

Private/stored jobs menu

Private/stored jobs menu

COPIES=X

Information menu

Information menu Explanation

Paper-handling menu Item/default Values Explanation

Paper-handling menu

TYPE=NORMAL Normallow High Vellum

ROUGH=HIGH VELLUM=VELLUM

Print-quality menu

Print-quality menu Values Explanation

Printing menu

Printing menu Values Explanation

PCL Font Internal

PCL Symbol

ERRORS=OFF

SOURCE=INTERNAL Soft

Configuration menu

Configuration menu Values Explanation

TIMEOUT=OFF Hour

JAM RECOVERY= Auto

Maintenance OFF

Clearable JOB

Menu

O menu Values Explanation

EIO menu HP LaserJet 5100tn and 5100dtn printers

EIO menu for networked printers Values Explanation

EIO menu for networked printers Values

Explanation

Resets menu

Resets menu Explanation

Service mode

Service menu

To use service mode

Count

Value

Service Menu

Maintenance page count, interval, and reset

Service Mode

Serial number

Cold reset paper size

Diagnostics

Clear event log

Cold reset

Testing the printer

Resetting the printer

Clearing Nvram

MS-DOS system configuration

System configuration

Printer I/O configuration

Parallel MS-DOS commands

Printer maintenance

Cleaning the printer and accessories

Inside, general

Cleaning spilled toner

Using the printer cleaning

Expected life of components

Preventive maintenance

Reset maintenance count

Expected life of components Part name Part number

Functional information

Functional information Q1860-90918

Printer subsystems

Paper-feed subsystem

Power supply system

Ac/dc power distribution

Overcurrent overvoltage protection

High-voltage power distribution

High-voltage power supply circuit

Dc controller PCA

Toner-cartridge detection

Dc controller system

Q1860-90918 Functional information

Paper-motion monitoring and control

Solenoids, sensors, clutches, and switches

Laser and scanner drive

Engine test

Motors

Main-motor control

PowerSave

Resolution Enhancement technology

Formatter system

EconoMode

Input/output

Printer memory

Read-only memory and random-access memory RAM

Nonvolatile random-access memory

Memory Enhancement technology

Protect

Control panel

Image-formation system

Image-formation system

Toner cartridge

Cleaning the drum

Cleaning the drum

Photosensitive drum

Conditioning the drum

Primary charging roller

Writing the image

Writing the image

Developing the image

Developing the image

Transferring the image

Transferring the image

Image fusing/variable fusing temperature

Variable fusing temperature

Fusing temperature control

Paper feed system

Paper path

Clutches and sensors

Printing from Tray

Tray 2 Paper path

Paper skew correction

Printing from the optional 500-sheet and 250-sheet Trays

Sheet paper feeder

500-sheet paper feeder

Paper jam

Duplexer

Reversing/refeed system

Reversing system

Duplexer

Paper jam in the duplexer

Basic sequence of operation

Basic sequence of operation Period Timing Purpose Remark

Functional information Q1860-90918

Q1860-90918 Functional information

Functional information Q1860-90918

Removing and replacing parts

Removing and replacing parts Q1860-90918

User-installable accessories

Memory upgrade

If an optional duplexer is installed

Checking memory installation

Installing EIO cards or mass-storage devices

Paper-handling accessories

Removing loose toner

Before you begin

Replacing printer parts

Required tools

Parts removal order

Covers

Rear door and rear output bin

Rear door and rear output bin removal 2

Fuser

Fuser removal rear view of printer

Top cover

Top cover removal 1

Top cover removal 2

Control panel overlay and control panel

Control panel overlay removal

Control panel removal

Toner cartridge door assembly

Front cover and Tray

Front cover removal

Front cover pins

Front cover pins removal

Face-down cover

Face-down cover removal 1

Left and right side covers

Side covers removal

Tray 1 inner cover

Tray 1 inner cover removal 1 of 2, inner cover flag

Tray 1 inner cover removal 2 of 2, front of printer

Right and left corner covers

Corner covers removal

Internal assemblies

Internal assemblies Explanation

Transfer-roller assembly

Transfer-roller assembly removal 1

Transfer-roller assembly removal 2

To reinstall

Reinstalling the transfer roller

Paper-handling PCA

Paper-handling PCA removal

Top margin adjustment

Adjusting the top margin

Location of VR401 on the paper-handling PCA

Main gear assembly

Main gear assembly removal 1 of 2, left side

Main gear assembly removal 2

Pickup gear assembly

Pickup gear assembly removal left side of printer

Tray 1 pickup solenoid

Tray 1 pickup solenoid removal

Fan

Fan removal right side of printer

Formatter assembly

Formatter assembly removal

Tray 1 roller

Tray 1 roller removal

Tray 1 separation pad

Tray 1 separation pad removal 2

Tray 2 pickup roller

Tray 2 pickup roller removal bottom of the printer

Tray 2 separation pad

Tray 2 separation pad removal 1

Paper-feed roller assembly

Page

Dc controller and power supply

Dc controller assembly removal 1 of 3, rear view of printer

Dc controller assembly removal 2 of 3, long screws

Paper-feed belt assembly

Paper-feed belt assembly removal 1

Paper-feed belt assembly removal 2

Tray 1 shaft

Tray 1 shaft removal 1 of 2, right side view of printer

Tray 1 shaft removal 2

Tray 2 shaft

Tray 2 shaft removal left side view of printer

Reinstallation of Tray 2 shaft

Tray 1 lift plate

Tray 1 lift plate removal

Paper guide

Paper guide removal

Top-of-page sensor

Top-of-page sensor removal bottom of printer

Face-down bin-full sensor lever

Face-down bin-full sensor lever removal

Accessory interface connector

Accessory interface connector removal left side of printer

Registration assembly

Registration assembly removal 1

Registration assembly removal 2

Upper delivery assembly

Upper delivery assembly removal

Delivery roller

Delivery roller removal 1

Delivery roller removal 2

Laser/scanner assembly

Laser/scanner assembly removal top, inside view of printer

Main motor

Main motor removal rear view

Toner cartridge guides

Toner cartridge guide removal shown from right side

Power inlet assembly

Power inlet assembly removal

Optional 250-sheet feeder

Separation pad

Pickup roller

Sensing flag

Optional 250-sheet feeder sensing flag removal 1

Control PCA

Optional 250-sheet feeder control PCA removal 1

Optional 250-sheet feeder control PCA removal 3

Paper-size spring assembly

Optional 500-sheet feeder

Covers and base frame

Sheet feeder removal 2 of 2, top view with covers removed

Tray indicator assembly

Tray indicator assembly removal

Left front corner cover installation

Installing the left front corner cover

Sheet feeder feed roller

Sheet feeder feed roller removal

Sheet feeder pickup roller

Sheet feeder pickup roller removal 1

Sheet feeder PCAs

Sheet feeder power connector

Power connector removal

Sheet feeder separation roller

Separation roller removal

Troubleshooting

Troubleshooting process

Major steps for troubleshooting

Troubleshooting process flow

See Printer Messages on 193 to Understand Correct Problem

See Image quality on 207 Compare pages To samples

Troubleshooting the printing system

Preliminary operating checks

Power on

Power on defect or blank display Problem Action

No ac power Cause Action

No dc power Cause Action

Display

Engine test button location

Printing an engine test

Event log

View the event log at the control panel

Print the event log

Interpret the event log

Printer messages

Printer messages Message Explanation or recommended action

Install Toner

Do not Power OFF

Do not Power OFF Flash Device

Initializing

Resend Upgrade

Memory Settings

Maintenance

Changed

Store JOB

Printer Error

Unable to

USE Type

Transmission

Buffer Overflow

Parallel I/O

Unexpected

Fuser Error

Printer Error

Cycle Power to

Cycle Power

Device Failure

Check Cables

8x.yyyy

General paper-path troubleshooting

ProblemAction

Paper-path test

Press Item until Print Paper Path Test appears

Information pages

Menu map

Configuration

Configuration page see for category explanations

Verify the installed options

Configuration page categories

Image quality

Check the toner cartridge

Image quality checks Action

EconoMode

Image defects

Black lines in paper path direction Possible cause Action

Correctly Defective toner cartridge

Black

Possible cause Action

Blank

Cartridge

HP LaserJet Printer Family Paper Specification Guide

Character voids and dropouts

Creases Possible cause Action

Curl Possible cause Action

Dark print Possible causeAction

Dirt on back Possible cause Action

Distorted image Possible cause Action

Dots in the paper-path direction

Faded or light print Possible cause Action

Gray background Possible cause Action

Improperly

Loose toner or toner smear

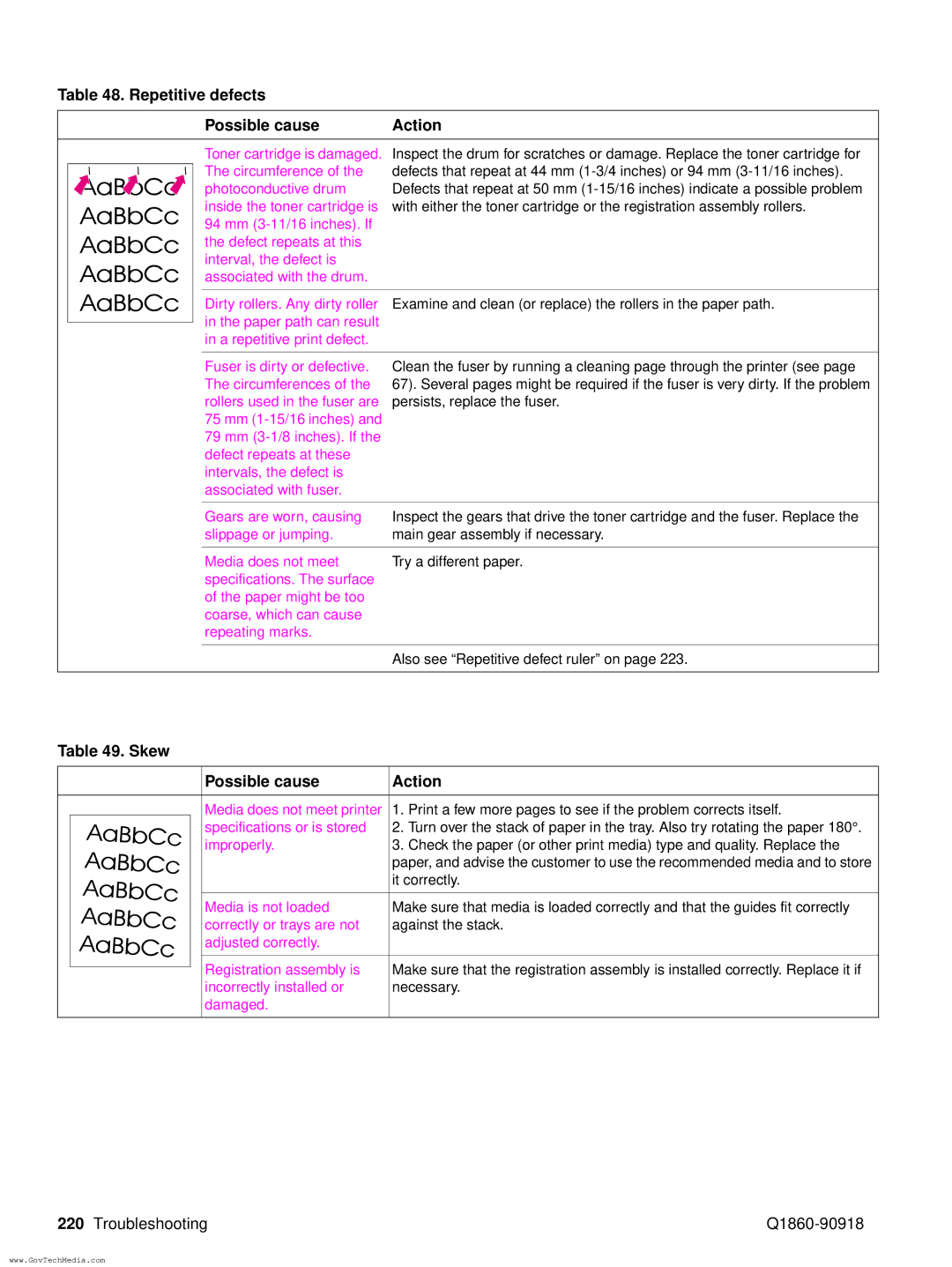

Repetitive defects

Skew Possible cause Action

Smudged lines either direction Possible cause Action

Toner specks see also Dots on Possible cause Action

White lines in the paper-path direction

Damage to the print drum

Repetitive defect ruler

Repetitive defect ruler

Image system troubleshooting

Half self-test functional check

Drum rotation functional check

Jetdirect configuration

Interface troubleshooting

EIO troubleshooting

Communications check

Jetdirect configuration

Reference diagrams

Locations of components

Paper path clutches, solenoids, and motors

Sheet paper feeder

Sheet paper feeder

Sheet paper feeder

Sheet paper feeder

Duplexer

Troubleshooting Q1860-90918

Q1860-90918 Troubleshooting

Sensors and signals

Paper path and components see , , and for accessories

Sensors, switches, clutches, and solenoids Name

Printer sensors

Duplexer sensors

Printer switches

Sheet feeder switches

Motors, fans, and fuser heaters see on

FM1

Connectors main unit

Connectors duplexer and 250-sheet paper feeder

Connectors 500-sheet paper feeder

PCAs

PCA duplexer PCAs Name Function

PCA

Clutches and solenoids

Clutches and solenoids duplexer Symbol Name of symbol Code

OFF A4R

Dc controller inputs and outputs

Dc controller I/O 1

Dc controller I/O 2

Dc controller I/O 3

Dc controller I/O 4

Troubleshooting Q1860-90918

Parts and diagrams

Parts and diagrams Q1860-90918

Support

Ordering parts and supplies, and getting support

Related documentation and software

Ordering parts

Accessories and supplies

Common hardware and replacement cables

Screws used in the printer Description Part number

Replaceable cables Description Part Number

Diagrams and parts lists

Assembly locations 1

Registration roller assembly Fuser Tray Tray 2 pickup roller

Parts and diagrams Q1860-90918

Q1860-90918 Parts and diagrams

Internal components 1

Q1860-90918 Parts and diagrams

Internal components 2

Q1860-90918 Parts and diagrams

See

See

Parts and diagrams Q1860-90918

Q1860-90918 Parts and diagrams

Parts and diagrams Q1860-90918

Paper feed roller assembly

Item number Part number Quantity Description

RG5-4916-000CN Registration roller assembly

Q1860-90918 Parts and diagrams

Parts and diagrams Q1860-90918

Q1860-90918 Parts and diagrams

Parts and diagrams Q1860-90918

See figure

Fuser Item number Part number Quantity Description

Sheet feeder Item number Part number Quantity Description

Parts and diagrams Q1860-90918

Sheet feeder 1 Item number Part number Quantity Description

Sheet feeder 2

Sheet feeder 2 Item number Part number Quantity Description

Parts and diagrams Q1860-90918

Duplexer Item number Part number Quantity Description

Alphabetical parts list

Alphabetical parts list Description Part number

Alphabetical parts list Description Part number

Cable, ribbon, paper-handling PCA to dc controller

Alphabetical parts list Description Part number

Numerical parts list

Numerical parts list Part number Description

Numerical parts list Part number Description

Cable, ribbon, paper-handling PCA to dc controller

Numerical parts list Part number Description

Parts and diagrams Q1860-90918

Index

Index

See also removing

EIO

IPX/SPX

MS-DOS

Q1860-90918

Index

Q1860-90918 Index

TCP/IP

See also testing

Index Q1860-90918

Page

Copyright 2002 Hewlett-Packard Company