PCW-5181

Industrial Devices Corporation

Page

Version

Revision History

Page

Table of Contents

END of Manual

Impulse Overview

Feature Function

This page intentionally left blank

Shipping Contents

This page intentionally left blank

Typical Impulse Applications

Connecting and Installing Your Impulse

Read This Page Before Your Begin

Connecting an IDC Motor

Connecting a Motor to the Impulse

Connecting a Non-IDC Motor

Making RS-232/RS-485 Connections

Serial Communication Connections

SS-RS232

Multi-Dropping with RS-485

Daisy-Chaining Impulse Drives

Rules for Daisy Chain Operation

PC/Host RS-232C Device

Jumpers Pin D

Troubleshooting RS-232C Communication Problems

Using a Keypad with Impulse RS232C

Connecting an IDC Keypad

Using a Keypad with Impulse RS485

FP100 Keypad

LED Diagnostic Indications

Connecting AC Power

Diagnostic LED Indications LED Signal

Application Notes

Connecting Inputs and Outputs

Mounting the Impulse Drive

Environmental and Installation Requirements

Mounting Arrangements

Impulse with DIN-rail Mounting Bracket P/N PCS-5111

Impulse Dimensions

Impulse with Screw-type Mounting Bracket P/N PCS-5110

Installation

Installation of Bracket DIN Rail Bracket Shown

Inserting and Removing Mounting Brackets from the Impulse

Removal

Mounting the Impulse on the DIN-Rail

Impulse DIN-Rail Mounting

Removal of Impulse from the DIN-Rail

Mounting

This page intentionally left blank

Installing Application Developer on Windows 95/98/2000/ME/NT

Configuring Impulse with Application Developer

Using Application Developer

Upload Project

Open an Existing Project

Launch Now

Using the Project Wizard

Select Motor Only

Configuring Impulse with Application Developer

Configuring Impulse with Application Developer

Configuring Impulse with Application Developer

Axis Setup

Fine-Tuning Your Application

Toolbar Buttons

See Appendix C to Edit a Motor

Motor

Mechanics

Command Signal Configuration

Command

Jog Input Configuration

Numeric Precision

Smoothness Xtreme Smoothing

Adjusting X-Smoothness #1, #2, #3

Smoothness #1

Smoothness #3

Smoothness #2

Current Reduction Mode

Advanced Advanced Tuning

Anti-Resonance

Profiling

Descriptions Input Descriptions

Setup

Stall Detection

Inactive

Output Descriptions

Stored Move Setup Editing Stored Moves

Configuring Impulse with Application Developer

File Menu

Setup Menu

Edit Menu

Communications Menu

Run Menu

View Menu

Updating Your Impulse Operating System

This page intentionally left blank

Keypad Features

Configuring Impulse with an IDC Keypad

Introduction to the FP100 Impulse Keypad

Adjusting Contrast

Keypad Hardware Features

DIP Switch Settings

Remote-Mounting the Keypad

Keys F1-F2-F3

Functions of the FP100 Keypad Keys

RUN Menu Keys

Keys

Menu Options

Keypad Menu Structure

FP100 Main Menu and Sub-Menus

JOG F3

General Rules for Using the Keypad

Apply Power to the Keypad

RUN Using the RUN Menus

File Menu File Options

Edit Using the Edit Menus

Opening a Project File

Saving a Project File

Sub-Menu Setup Parameter Description of Setup Parameter

Using the Setup Sub-Menus for Configuring Your System

Renaming an Open Project File

Requires Open File

Help Using the Help Menu

DEL Using the DEL Delete menu

Copy Using the Copy Menu

To Delete a Project File

−−−↑ Motor Type ↓−−− None

Parameter Being Configured example Motor Type

Using the Edit Setup Menus to Configure the Impulse

Configuring Impulse with the Keypad

Configuring Motor Type

Open a File

Configuring Shutdown Polarity

Configuring Motor Direction

To Probe the Motor

Configuring Stop Rate

Configuring Drive Resolution

Configuring Jog Parameters

Drive Resolution 25000

Configuring Units Gear Ratio

Configuring Mechanical Units User Units

User Units

Units Gear Ratio Numerator

↑ X-Sm1 L1 Value ↓ ↑ X-Sm1 L2 Value ↓ Sm1 Test Speed RPS

Motor Tuning Setup X-Smoothness

L2 ←

Configuring Anti-Resonance Gain

Configuring Stop Mode Current-Reduction Timeout I-STOP

Configuring Profiling Parameters

Configuring Encoderless Stall-Detection Olsd

Configuring Idle Mode Current Reduction Parameters

Idle Mode Tmeout Off Idle Mode %Redct

Stall Detection

Setup

Configuring Inputs

←↑ Input #1 ↓→

Configuring Input/Output Polarities

Configuring Outputs

↑ Output #1 ↓

Stored-Move Profiles

Move Menus Using Stored Moves

Stored Moves

Configuring Scan Time

Configuring Stored-Move Profiles

Move Selection Input Scan Time

Move Sel Scan Time 0 ms

Unit Number

Very Important! Send the File to the Drive

Hardware Reference

Impulse Specifications

Extending the Cable Length to Your Keypad

Remote Mounting Your Keypad

End View of Wall-Mounted Keypad with Cover Removed

Keypad Mounting Template

Keypad Mounting *Template

Digital Inputs

Impulse I/O Schematics

Digital Output

Single-Ended Installation

Fault Output

Differential Installation

Step, Direction, and Shutdown Inputs

RPS-1

SS-RS232

Accessory P/N & Description

PCS-5004

DB25BO Screw Terminal Breakout Board

Pin Connector on Impulse Drive

SS-IO/SS-IO-6 Cables

S12 Hybrid Step Motor

Impulse-Applicable IDC Motors

Electrical Specs S12T

Mechanical Specs S12T

IDC Motor Wiring

S21, S22, S23 Hybrid Step Motor Specifications

Electrical Specs S21T S21V S22T S22V S23T S23V

S22T S22V S23T

Electrical Specs S32T S33T

S32, S33 Hybrid Step Motor Specifications

S32T S33T

Electrical Specs P21V P22V

P21, 22 Hybrid Step Motor Specifications

P21V P22V

IDC Motor Wiring

31, 32, 33Step Motor Specifications

This page intentionally left blank

Troubleshooting Table

Troubleshooting the Impulse

Symptom Possible Causes Possible Remedies

Troubleshooting Your Impulse

Limits Tables

This page intentionally left blank

Product Support

Warranty & Repairs

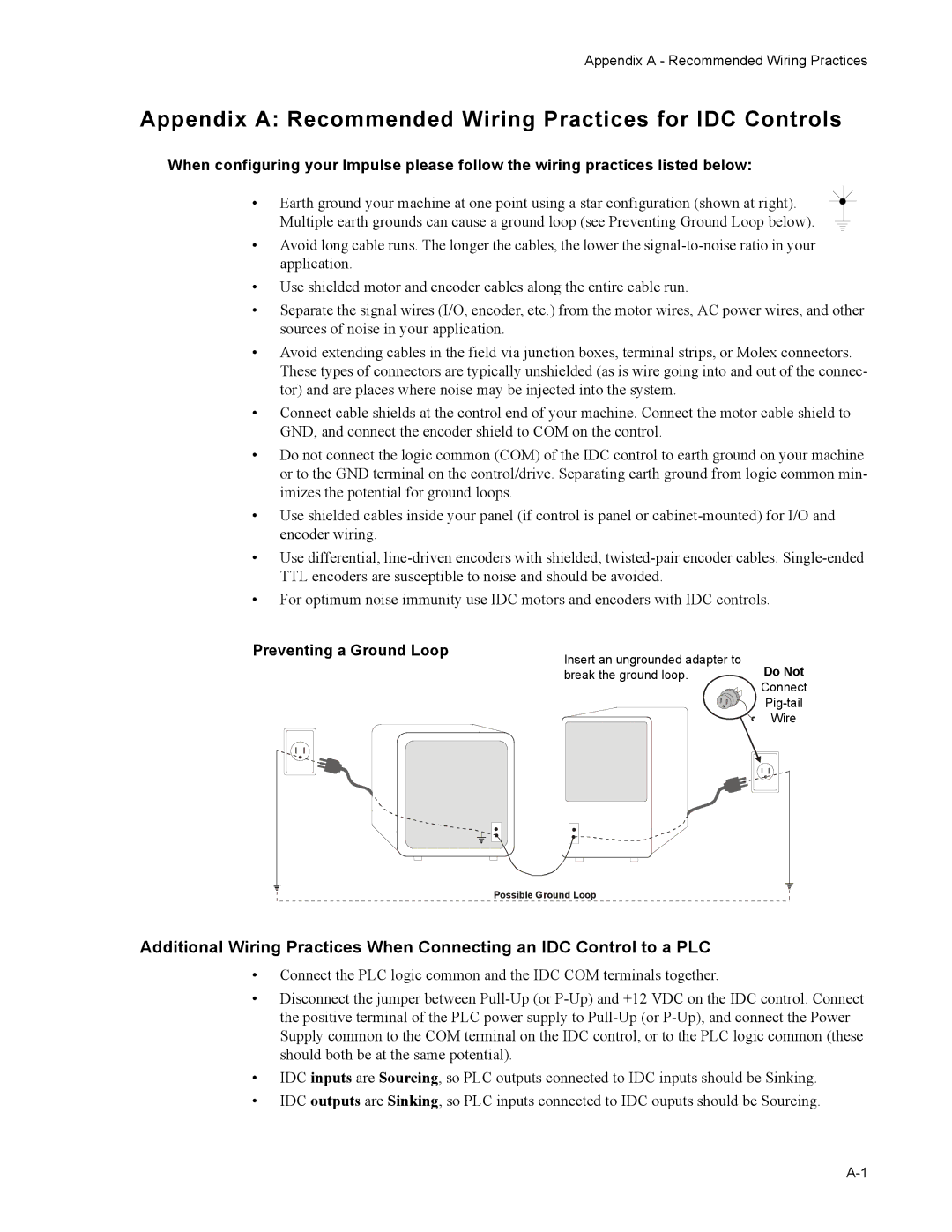

Preventing a Ground Loop

Appendix a Recommended Wiring Practices for IDC Controls

Appendix a Recommended Wiring Practices

Communications Protocol

Appendix B Impulse Advanced Programming

Byte Receive Time Out

Reading and Writing Parameter Data

Receive Buffer Overrun

Read Queries

Interpreting the Transmission Status Response

Write Requests

01 71 00 00 00 00 72

01 00 00 00 01

Serial Jog Velocity RAM Only

User Accessible Parameters

Description Determines the acceleration rate value in RPS2

Jog Acceleration Rate

28h

Parameters

Formulas

Formula

Serial Port Stored Move Selection RAM Only

Commanded Velocity RAM Only

Commanded Position Counter RAM Only

Stored Drive Faults Reserved Eeprom Parameter

Formulas N/A Index

Formulas N/A Index Parameter Description

Eeprom Enable Switch

Description Determines the operational status of the drive

System Status RAM Only

Unit Address

Defaults

Parameters

Formulas

Parameter Formula

Software Shutdown RAM Only

Motor Wiring

Appendix C Using Non-IDC Motors with the Impulse

Custom or User-Defined Motors

Smoothness L1 and L2

Test Speeds 1, 2

Dynamic Smoothing

Anti -Resonance

Index

Faults

Index

Do Not Print This Inserted as Placeholder

Mail info@idcmotion.com

Industrial Devices Corporation