Frame Rail Installation

Tack Welding Frame Rails: (continued)

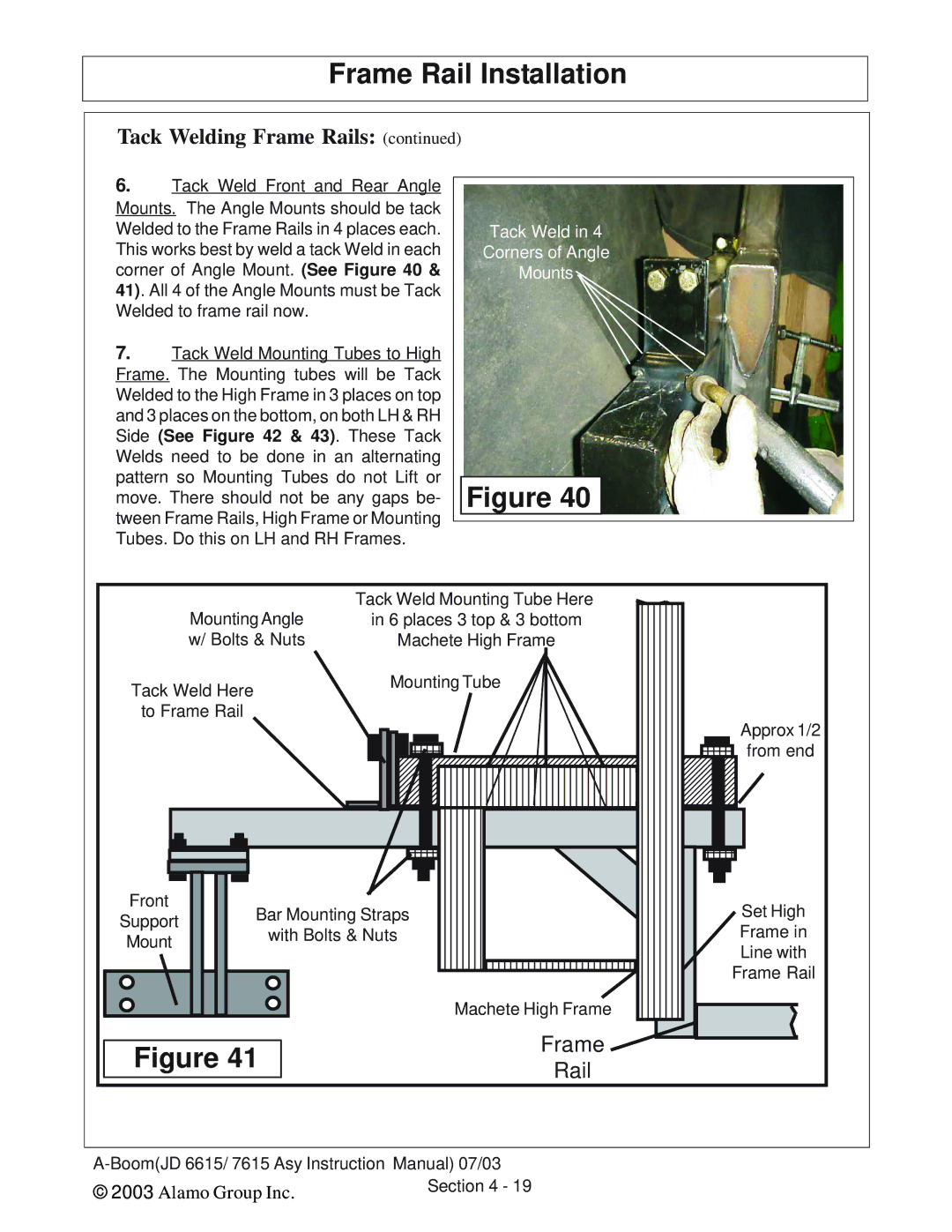

6.Tack Weld Front and Rear Angle Mounts. The Angle Mounts should be tack

Welded to the Frame Rails in 4 places each. | Tack Weld in 4 |

This works best by weld a tack Weld in each | Corners of Angle |

corner of Angle Mount. (See Figure 40 & | Mounts |

41). All 4 of the Angle Mounts must be Tack |

|

Welded to frame rail now. |

|

7.Tack Weld Mounting Tubes to High Frame. The Mounting tubes will be Tack Welded to the High Frame in 3 places on top and 3 places on the bottom, on both LH & RH Side (See Figure 42 & 43). These Tack Welds need to be done in an alternating

pattern so Mounting Tubes do not Lift or

move. There should not be any gaps be- Figure 40 tween Frame Rails, High Frame or Mounting

Tubes. Do this on LH and RH Frames.

| Tack Weld Mounting Tube Here |

Mounting Angle | in 6 places 3 top & 3 bottom |

w/ Bolts & Nuts | Machete High Frame |

Tack Weld Here | Mounting Tube |

| |

to Frame Rail |

|

|

| Approx 1/2 | |

|

| from end | |

Front | Bar Mounting Straps | Set High | |

Support | |||

with Bolts & Nuts | Frame in | ||

Mount | |||

| Line with | ||

|

| ||

|

| Frame Rail | |

|

| Machete High Frame | |

Figure 41 | Frame | ||

Rail | |||

|

| ||

© 2003 | Alamo Group Inc. | Section - 19 |

|