MODEL 3081 pH/ORP | SECTION 8.0 |

| PROGRAMMING FOR pH MEASUREMENTS |

8.4 DIAGNOSTIC PARAMETERS

8.4.1 Purpose

This section describes how to do the following:

1.change the standardization or reference offset,

2.enable and disable sensor diagnostics,

3.enable and disable glass impedance temperature compensation,

4.set the high and low warning and failure limits for the glass electrode.

5.set the high and low warning and failure limits for the reference electrode.

8.4.2 Definitions

1.STANDARDIZATION (REFERENCE) OFFSET. The transmitter reading can be changed to match the reading of a sec- ond pH meter. If the difference (converted to millivolts) between the transmitter reading and the desired value exceeds the programmed limit, the transmitter will not accept the new reading. To estimate the millivolt difference, multiply the pH difference by 60. Refer to Section 7.6, Manual Calibration, for additional information. The standardization offset is also the absolute value of the actual cell voltage in pH 7 buffer. For certain types of

2.GLASS IMPEDANCE TEMPERATURE COMPENSATION. The impedance of the glass electrode changes with tem- perature. For changes in glass impedance to be a useful indicator of electrode condition, the measurement must be corrected to a reference temperature.

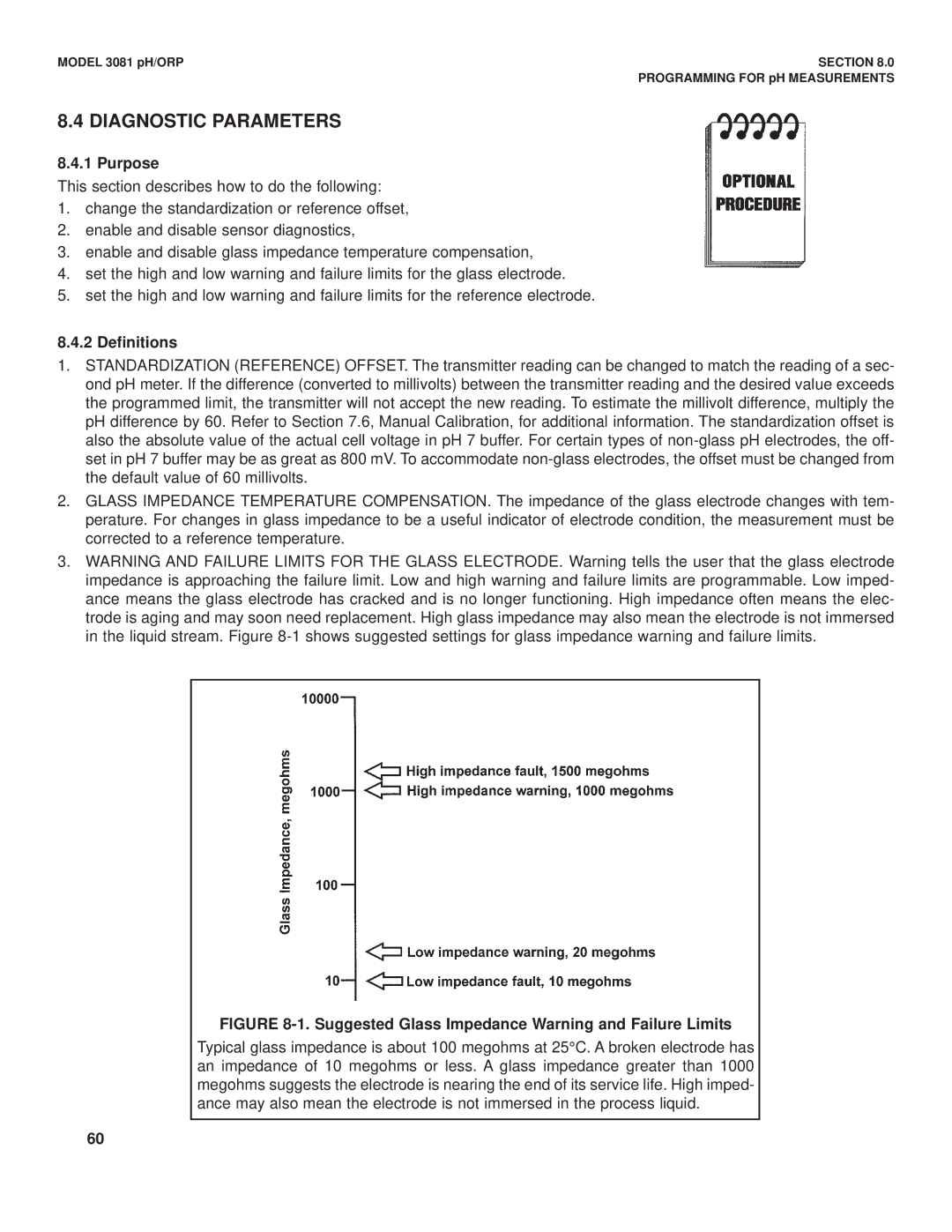

3.WARNING AND FAILURE LIMITS FOR THE GLASS ELECTRODE. Warning tells the user that the glass electrode impedance is approaching the failure limit. Low and high warning and failure limits are programmable. Low imped- ance means the glass electrode has cracked and is no longer functioning. High impedance often means the elec- trode is aging and may soon need replacement. High glass impedance may also mean the electrode is not immersed in the liquid stream. Figure

FIGURE 8-1. Suggested Glass Impedance Warning and Failure Limits

Typical glass impedance is about 100 megohms at 25°C. A broken electrode has an impedance of 10 megohms or less. A glass impedance greater than 1000 megohms suggests the electrode is nearing the end of its service life. High imped- ance may also mean the electrode is not immersed in the process liquid.

60