MODEL 3081 pH/ORP

PROGRAM

dIAGnOSTIC

EXIT NEXT ENTER

PROGRAM

rOFFSt | 0 | 60 |

| ||

EXIT |

| ENTER | |||

|

|

|

|

| |

|

|

|

|

| |

PROGRAM |

|

|

|

| |

d I A G |

|

| |||

OFF |

| ||||

EXIT |

| ENTER | |||

|

|

|

|

|

|

|

|

|

|

|

|

PROGRAM |

|

|

|

| |

I M P t C |

|

|

|

|

|

| ON |

|

| ||

EXIT NEXT ENTER

PROGRAM

GFH | 1 | 500 | ||

EXIT |

| ENTER | ||

|

|

|

|

|

|

|

|

|

|

PROGRAM |

|

|

| |

GWJH | 1 | 000 | ||

EXIT |

| ENTER | ||

|

|

|

|

|

|

|

|

|

|

PROGRAM |

|

|

| |

GWJL |

| 020 | ||

0 | ||||

EXIT |

| ENTER | ||

|

|

|

|

|

|

|

|

|

|

PROGRAM |

|

|

| |

GFL |

| 0 1 0 | ||

0 | ||||

EXIT |

| ENTER | ||

|

|

|

|

|

|

|

|

| |

PROGRAM |

|

|

| |

CAL |

| 00 | ||

0 | ||||

EXIT |

| ENTER | ||

|

|

|

|

|

|

|

|

|

|

PROGRAM |

|

|

| |

rEF |

|

|

| |

| LO |

| ||

EXIT |

| ENTER | ||

|

|

|

|

|

SECTION 8.0

PROGRAMMING FOR pH MEASUREMENTS

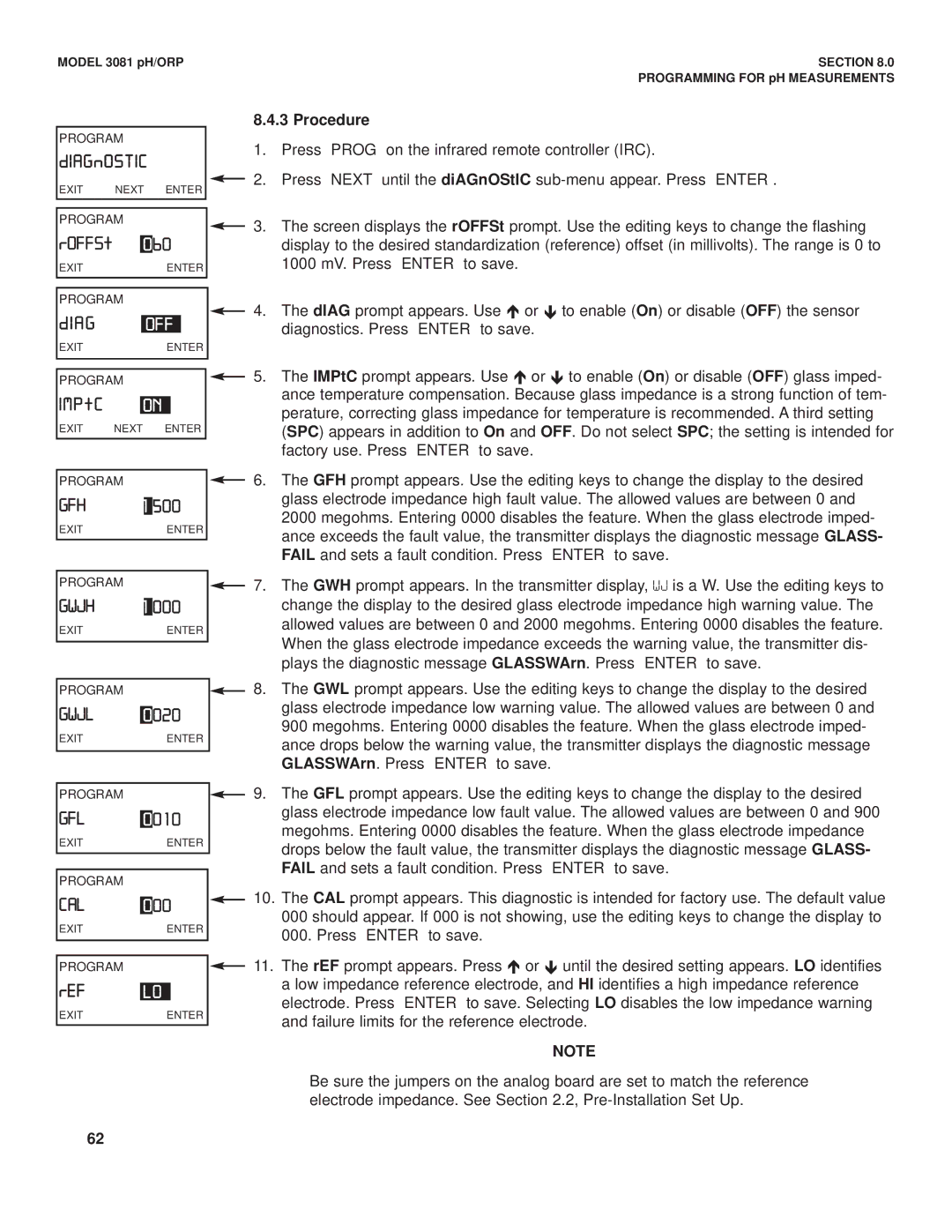

8.4.3 Procedure

1.Press PROG on the infrared remote controller (IRC).

2.Press NEXT until the diAGnOStIC

3.The screen displays the rOFFSt prompt. Use the editing keys to change the flashing display to the desired standardization (reference) offset (in millivolts). The range is 0 to 1000 mV. Press ENTER to save.

4.The dIAG prompt appears. Use Ï or Ð to enable (On) or disable (OFF) the sensor diagnostics. Press ENTER to save.

5.The IMPtC prompt appears. Use Ï or Ð to enable (On) or disable (OFF) glass imped- ance temperature compensation. Because glass impedance is a strong function of tem- perature, correcting glass impedance for temperature is recommended. A third setting (SPC) appears in addition to On and OFF. Do not select SPC; the setting is intended for factory use. Press ENTER to save.

6.The GFH prompt appears. Use the editing keys to change the display to the desired glass electrode impedance high fault value. The allowed values are between 0 and 2000 megohms. Entering 0000 disables the feature. When the glass electrode imped- ance exceeds the fault value, the transmitter displays the diagnostic message GLASS- FAIL and sets a fault condition. Press ENTER to save.

7.The GWH prompt appears. In the transmitter display, WJ is a W. Use the editing keys to change the display to the desired glass electrode impedance high warning value. The allowed values are between 0 and 2000 megohms. Entering 0000 disables the feature. When the glass electrode impedance exceeds the warning value, the transmitter dis- plays the diagnostic message GLASSWArn. Press ENTER to save.

8.The GWL prompt appears. Use the editing keys to change the display to the desired glass electrode impedance low warning value. The allowed values are between 0 and

900megohms. Entering 0000 disables the feature. When the glass electrode imped- ance drops below the warning value, the transmitter displays the diagnostic message GLASSWArn. Press ENTER to save.

9.The GFL prompt appears. Use the editing keys to change the display to the desired glass electrode impedance low fault value. The allowed values are between 0 and 900 megohms. Entering 0000 disables the feature. When the glass electrode impedance drops below the fault value, the transmitter displays the diagnostic message GLASS- FAIL and sets a fault condition. Press ENTER to save.

10.The CAL prompt appears. This diagnostic is intended for factory use. The default value

000should appear. If 000 is not showing, use the editing keys to change the display to

000.Press ENTER to save.

11.The rEF prompt appears. Press Ï or Ð until the desired setting appears. LO identifies a low impedance reference electrode, and HI identifies a high impedance reference electrode. Press ENTER to save. Selecting LO disables the low impedance warning and failure limits for the reference electrode.

NOTE

Be sure the jumpers on the analog board are set to match the reference electrode impedance. See Section 2.2,

62