MODEL 3081 pH/ORP | SECTION 9.0 |

| CALIBRATION OF ORP MEASUREMENTS |

9.5 Standardization

9.5.1 Purpose

This section describes how to prepare ORP standard solutions and how to make the transmitter reading match the ORP of the standard. Procedures for making ORP standards are taken from ASTM Method

9.5.2 Preparation of ORP Standard Solutions

ASTM D

Iron (II) - iron (III) standard is available from Rosemount Analytical as PN

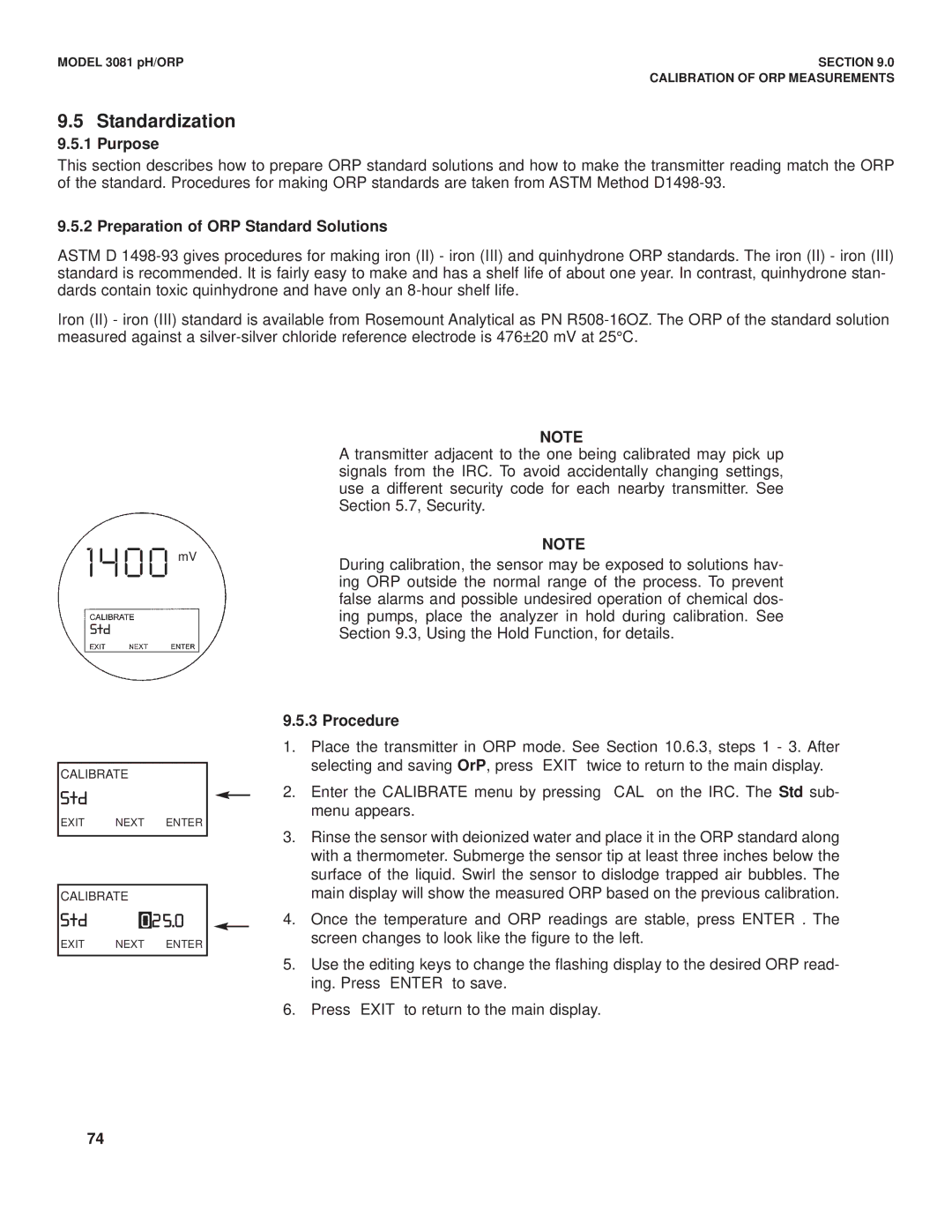

1 4 0 0 mV

Std

CALIBRATE

Std

EXIT NEXT ENTER

CALIBRATE

Std |

| 0 | 2 5.0 |

EXIT | NEXT ENTER | ||

NOTE

A transmitter adjacent to the one being calibrated may pick up signals from the IRC. To avoid accidentally changing settings, use a different security code for each nearby transmitter. See Section 5.7, Security.

NOTE

During calibration, the sensor may be exposed to solutions hav- ing ORP outside the normal range of the process. To prevent false alarms and possible undesired operation of chemical dos- ing pumps, place the analyzer in hold during calibration. See Section 9.3, Using the Hold Function, for details.

9.5.3 Procedure

1.Place the transmitter in ORP mode. See Section 10.6.3, steps 1 - 3. After selecting and saving OrP, press EXIT twice to return to the main display.

2.Enter the CALIBRATE menu by pressing CAL on the IRC. The Std sub- menu appears.

3.Rinse the sensor with deionized water and place it in the ORP standard along with a thermometer. Submerge the sensor tip at least three inches below the surface of the liquid. Swirl the sensor to dislodge trapped air bubbles. The main display will show the measured ORP based on the previous calibration.

4.Once the temperature and ORP readings are stable, press ENTER . The screen changes to look like the figure to the left.

5.Use the editing keys to change the flashing display to the desired ORP read- ing. Press ENTER to save.

6.Press EXIT to return to the main display.

74