MODEL 3081 pH/ORP |

| SECTION 12.0 | |

|

|

| TROUBLESHOOTING |

|

|

|

|

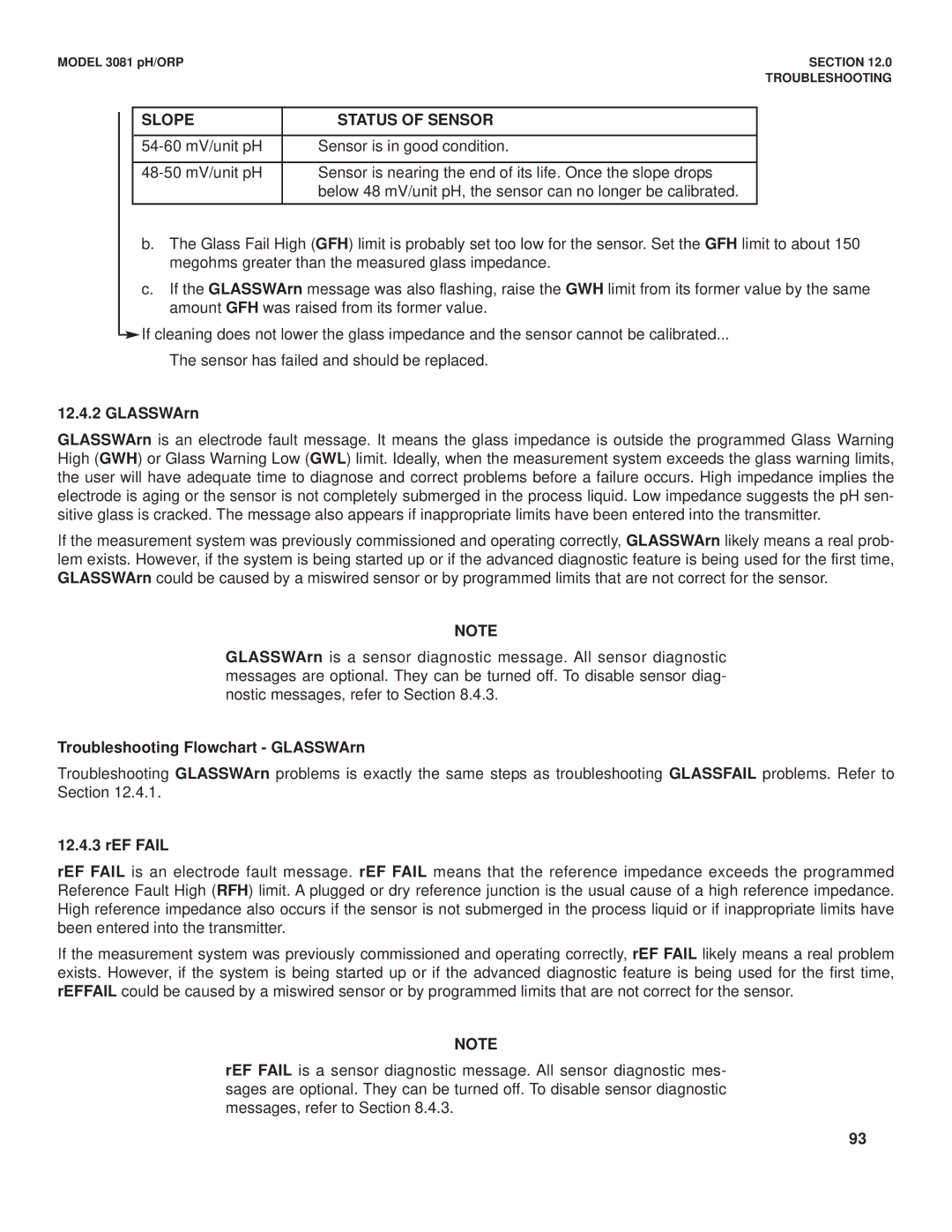

| SLOPE | STATUS OF SENSOR |

|

|

|

|

|

| Sensor is in good condition. |

| |

|

|

|

|

| Sensor is nearing the end of its life. Once the slope drops |

| |

|

| below 48 mV/unit pH, the sensor can no longer be calibrated. |

|

b.The Glass Fail High (GFH) limit is probably set too low for the sensor. Set the GFH limit to about 150 megohms greater than the measured glass impedance.

c.If the GLASSWArn message was also flashing, raise the GWH limit from its former value by the same amount GFH was raised from its former value.

If cleaning does not lower the glass impedance and the sensor cannot be calibrated...

The sensor has failed and should be replaced.

12.4.2 GLASSWArn

GLASSWArn is an electrode fault message. It means the glass impedance is outside the programmed Glass Warning High (GWH) or Glass Warning Low (GWL) limit. Ideally, when the measurement system exceeds the glass warning limits, the user will have adequate time to diagnose and correct problems before a failure occurs. High impedance implies the electrode is aging or the sensor is not completely submerged in the process liquid. Low impedance suggests the pH sen- sitive glass is cracked. The message also appears if inappropriate limits have been entered into the transmitter.

If the measurement system was previously commissioned and operating correctly, GLASSWArn likely means a real prob- lem exists. However, if the system is being started up or if the advanced diagnostic feature is being used for the first time, GLASSWArn could be caused by a miswired sensor or by programmed limits that are not correct for the sensor.

NOTE

GLASSWArn is a sensor diagnostic message. All sensor diagnostic messages are optional. They can be turned off. To disable sensor diag- nostic messages, refer to Section 8.4.3.

Troubleshooting Flowchart - GLASSWArn

Troubleshooting GLASSWArn problems is exactly the same steps as troubleshooting GLASSFAIL problems. Refer to Section 12.4.1.

12.4.3 rEF FAIL

rEF FAIL is an electrode fault message. rEF FAIL means that the reference impedance exceeds the programmed Reference Fault High (RFH) limit. A plugged or dry reference junction is the usual cause of a high reference impedance. High reference impedance also occurs if the sensor is not submerged in the process liquid or if inappropriate limits have been entered into the transmitter.

If the measurement system was previously commissioned and operating correctly, rEF FAIL likely means a real problem exists. However, if the system is being started up or if the advanced diagnostic feature is being used for the first time, rEFFAIL could be caused by a miswired sensor or by programmed limits that are not correct for the sensor.

NOTE

rEF FAIL is a sensor diagnostic message. All sensor diagnostic mes- sages are optional. They can be turned off. To disable sensor diagnostic messages, refer to Section 8.4.3.

93