00809-0100-4663, Rev BA January

Reference Manual

Page

North American Response Center

Customer Central

Page

Table of Contents

Section

Operation Sensor Installation

Reference Data Appendix B Approval Information

Maintenance Troubleshooting

Diagnostics

Appendix a

Appendix E

Digital Signal Processing

Universal Sensor Wiring Diagrams

Appendix D

Appendix H

Appendix F Resource Block

Appendix G

Transducer Block

TOC-6

System Description

Section Introduction

Service Support

Safety Messages

Explosions could result in death or serious injury

Section Installation

Mechanical Considerations

Transmitter Symbols PRE-INSTALLATION

Pipe Mounting

Installation

Procedures Mount the Transmitter

Environmental Considerations

Hardware Switches

Identify Options and Configurations

Conduit Ports Connections

Rosemount Electronics Board and Hardware Switches

Electrical Considerations

Conduit Cables

Power System Fuse Rating Manufacturer

Requirements for 12-42 V DC Power Supply

00809-0100-4663, Rev BA

Field Wiring

Characteristic

Ideal Specification

Foundation fieldbus Signal Connections Refer to -6 on

Transmitter Wiring Connection

Power Supply

Characteristics Terminators Fieldbus Segment Trunk Spur

Devices 1 through

Rosemount Sensors Transmitter to Sensor Wiring

Sensor Connections

Cable Requirements

Cable Shield

Rosemount 8732 Transmitter

Sensor to Remote Mount Transmitter Connections

Connect coil drive and electrode cables as shown in Figure

Rosemount 8705/8707/8711/8721

Rosemount

Section Configuration

Introduction Local Operator Interface Basic Features

Basic Set-up Parameters

Table Values

Data Entry

LOI Examples

Space

Stop Totalizer

Reset Totalizer

Table Value Example Select Value Example Display Lock

Start Totalizer

PV LRV

00809-0100-4663, Rev BA January LOI Menu Tree

Process Variables

Diagnostic

Messages

Review

PV Analog Output

Totalizer Setup

PV Primary Variable

PV -% Range

Flow Units

Basic Setup

Pulse Output

Tag

Fast Keys 2, 2

Special Volume Unit

Options for Flow Rate Units

Special Units

Base Time Unit

Base Volume Unit

Line Size

Conversion Number

Lower Range Value

PV URV

Upper Range Value

PV LRV

PV Damping

Calibration Number

Rosemount

Section Operation

Introduction Diagnostics

Diagnostic Controls

Transducer Block, Diagnostics

Basic Diagnostics

Advanced Diagnostics

8714i Result

8714i Results

Test Condition

Test Criteria

Sensor Signature

Sensor Calibration Result

Coil Circuit Result

Electrode Circuit Result

No Flow Limit

Re-Signature Meter

Recall Last Saved Values

Set Pass/Fail Criteria

License Key

Measurements

Licensing

License Status

Diagnostic Variables

Trims

Electronics Trim

Transducer Block, Diagnostics, Trims

Status

Auto Zero

Universal Trim

Additional Parameters

Advanced Configuration Detailed Setup

Display Language

Signal Processing

Time Limit

Control

Samples

Limit

Primary Variable Damping

Transducer Block, Detailed Setup, Device Info

Device Info

Low Flow Cutoff

Flange Type

Sensor Tag

DSP Software Rev

Construction Materials

Liner Material

Mode

Electrode Type

Electrode Material

Block Mode Normal

Block Mode Target

Block Mode Actual

Block Mode Permitted

Process Leak Protection Optional

Sensor Installation

Explosions could result in death or serious injury

Rosemount 8705 Sensor Support for Handling

Sensor Handling

Pipe Diameters

Sensor Mounting

Upstream/Downstream Piping

Sensor Orientation

Incline or Decline Orientation

Electrode Plane

Flow Direction

Grounding Ring

Installation Flanged Sensor

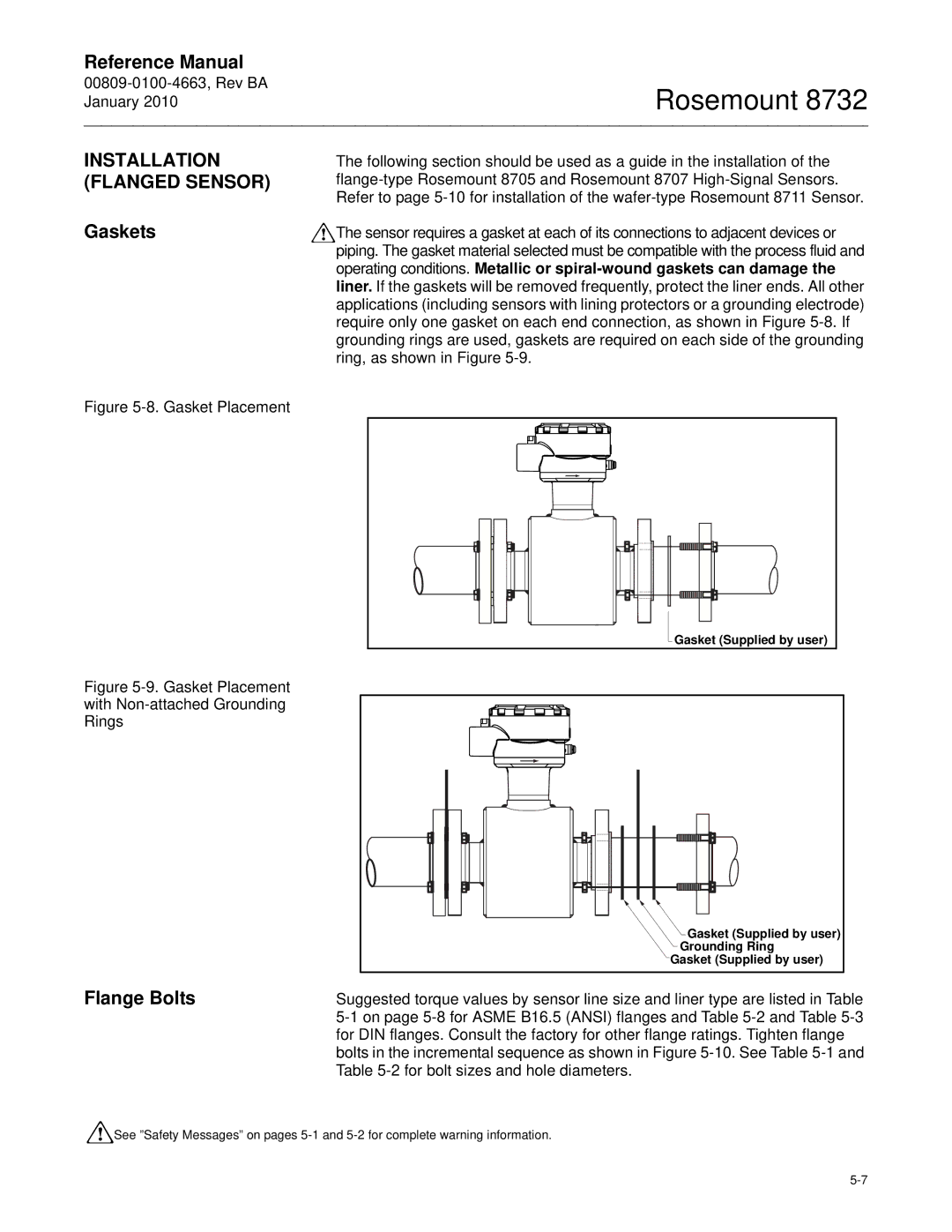

Gaskets

Flange Bolts

Class

PTFE/ETFE liner Polyurethane liner

PTFE/ETFE liner Size PN10 Code Line Size

Newton

Bolt

Installation Wafer Sensor

Gaskets Alignment and Bolting

Size Code Line Size

Centering Rings

Stud Specifications

Nominal Sensor Size Stud Specifications

Installation, Studs

Size Code Line Size Pound-feet Newton-meter

Installation Sanitary Sensor

See Figure Non-Conductive Pipe

14. Grounding with Grounding Rings or Lining Protectors

16. Grounding with Grounding Electrodes

Standard Housing Configuration

Process Leak Protection Optional

NPT Conduit Connection

Process Leak Containment

Relief Valves

Grounding Electrode Port

Safety Information

Maintenance Troubleshooting

Sensor

Installation Check and Guide

Wiring for Remote Configurations

Before You Begin Transmitter

Message Potential Cause Corrective Action

High Process Noise

Advanced Troubleshooting on next

Transmitter Troubleshooting

Advanced Troubleshooting-Rosemount

Symptom Potential Cause Corrective Action

Perform the auto zero function with full pipe and no flow

Wiring Errors Process Noise Installed Sensor Tests

Quick Troubleshooting

Location Equipment Connections

00809-0100-4663, Rev BA January Sensor Test

Sensor Circuit Diagram

Uninstalled Sensor Tests

Hazardous Location Certification

Uninstalled Rosemount 8711 Wafer Sensor Tests

Hazardous Location Certifications

Measuring at Connections N5, KD

Appendix a Reference Data

Functional Specifications

Ambient Temperature Limits Operating

Installation Coordination

Power Consumption

Switch-on current

Enclosure Rating

Output Signal

Foundation Fieldbus Specifications

Performance Specifications

Rosemount 8732E with Other Manufacturers’ Sensors

Rosemount 8732E with 8721 Sensor

Rosemount 8732E with Legacy 8705 Sensors

Rosemount 8732E with Legacy 8711 Sensors

Physical Specifications

Rosemount

European Directive Information

Appendix B Approval Information

Product Certifications

Approved Manufacturing Locations

All other Rosemount 8705/8707/8711/8721 Sensors

Electro Magnetic Compatibility EMC 2004/108/EC

Other Certifications Product Certification Code

Hazardous Locations Product Approvals Offering

Transmitter 8732E1 Sensor 8705 8707 8711 IECEx Category

Table B-4. IECEx Approvals Offering

Non-Hazardous

Equipment Category

Other Certifications Product Certification Code3

Hazardous Location Certifications

Transmitter Approval Information

Equipment Category 1 Dust Environment

E5 Explosion-Proof Approval 8732E

North American Certifications Factory Mutual FM

Canadian Standards Association CSA

N0 Division 2 Approval All transmitters

ND Atex Dust

European Certifications

E1 Atex Flameproof

ED Atex Flameproof

EF IECEx Flameproof

N1 Atex Type n

Remote Junction Box

E7 IECEx Flameproof

N7 IECEx Type n

Table B-6. Sensor Approval Information

E5 Explosion-Proof 8705 and 8711 Only

N0 Division 2 Approval for Non-Flammable Fluids All Sensors

N0 for 8721 Hygienic Sensor

N5 Division 2 Approval for Flammable Fluids All Sensors

Special Conditions for Safe USE

Rosemount 8732E Flow Transmitter

00809-0100-4663, Rev BA January Table B-7. Electrical Data

Rosemount 8732 Flow Transmitter

Rosemount 8705 and 8711 Sensors

In. sensor size

149F 65C 351F 177C 210F 99C

Figure B-1. Atex Installation

Figure B-2. Atex Installation

Figure B-3. Atex Installation

Figure B-4. Atex Installation

Figure B-5. Atex Installation

Figure B-6. Atex Installation 6

Figure B-7. FM Certified I.S. Output 1

Figure B-8. FM Certified I.S. Output 2

Figure B-9. FM Certified I.S. Output 3

Figure B-10. FM Certified I.S. Output 4

Figure B-11. CSA Certified I.S. Output 1

Figure B-12. CSA Certified I.S. Output 2

Figure B-13. CSA Installation

Figure B-14. Factory Mutual Hazardous Locations

Options for Accessing Diagnostics

Appendix C Diagnostics

Diagnostic Availability

Table C-1. Rosemount Magmeter Diagnostics

Tunable Empty Pipe Parameters

Licensing the 8732 Diagnostics

Licensing and Enabling

Tunable Empty Pipe Detection

Set the counts to

Optimizing Tunable Empty Pipe

Empty Pipe Trigger Level

Empty Pipe Counts

Turning Ground/Wiring Fault On/Off

Troubleshooting Empty Pipe

GROUND/WIRING Fault Detection

Ground/Wiring Fault Parameters

Turning High Process Noise On/Off

High Process Noise Detection

Hz Signal to Noise Ratio

White Noise

High Process Noise Functionality

Noise

Spike Noise

Establishing the baseline sensor signature

8714I Meter Verification

Sensor Signature Parameters

Initiating 8714i Meter Verification

8714i Meter Verification Test Parameters

8714i Meter Verification Test Results Parameters

8714i Meter Verification Test Scope

All

Viewing the 8714i Meter Verification Results

Electrode Circuit Verification

Transmitter Calibration Verification

Sensor Calibration Verification

Coil Circuit Verification

Optimizing the 8714i Meter Verification

Sensor Signature Values

8714i Meter Verification

Test

8714i Meter Verification Functionality

8714i Meter Verification Measurements

Electrode Circuit Resistance

Flowmeter Information and Configuration

Calibration Verification Report Parameters

Summary of Calibration Verification Results

Process leaks could result in death or serious injury

Appendix D Digital Signal Processing

Auto Zero

Procedures

How Does It Really Work?

Flow Rate

Time

When Should Signal Processing Be Used?

Appendix E Universal Sensor Wiring Diagrams

Rosemount Transmitter Sensor Manufacturer Number

Rosemount Sensors

Rosemount

8705/8707/8711/8721 Sensors to Rosemount Transmitter

Table E-3. Rosemount 8701 Sensor Wiring Connections

To Rosemount 8732 Transmitter

Rosemount Rosemount 8701 Sensors

Connecting Sensors of Other Manufacturers

Brooks Sensors

Model 5000 Sensor to Rosemount 8732 Transmitter

Rosemount Brooks Sensors Model

Model 7400 Sensor to Rosemount 8732 Transmitter

Electrodes

Table E-6. Endress and Hauser Sensor Wiring Connections

Endress and Hauser Sensors

Endress and Hauser Sensor to Rosemount 8732 Transmitter

Rosemount

Fischer and Porter Sensors

Model 10D1418 Sensor to Rosemount 8732 Transmitter

Coil Connections

Model 10D1419 Sensor to Rosemount 8732 Transmitter

Electrode Connections

Model 10D1430 Sensor Remote to Rosemount 8732 Transmitter

Model 10D1430 Sensor Integral to Rosemount 8732 Transmitter

Electrode

Connections

Rosemount Fischer and Porter Model 10D1465

Fischer and Porter Sensor to Rosemount 8732 Transmitter

Electrodes Coils Chassis Fuse

Rosemount Fischer and Porter Sensors

Rosemount Foxboro Series 1800 Sensors

Table E-13. Foxboro Generic Sensor Wiring Connections

Foxboro Sensors

Series 1800 Sensor to Rosemount 8732 Transmitter

Black

Series 1800 Version 2 Sensor to Rosemount 8732 Transmitter

8732

White

Rosemount Foxboro Series 2800 Sensors

Series 2800 Sensor to 8732 Transmitter

White Electrodes Black

Ground Coils Fuse

Rosemount Foxboro Sensors

Rosemount Kent Veriflux VTC Sensors

Kent Veriflux VTC Sensor

Veriflux VTC Sensor to 8732 Transmitter

+ 6 SCR

Rosemount Kent Sensors

Kent Sensors

Kent Sensor to Rosemount 8732 Transmitter

Coils Fuse

Rosemount Krohne Sensors

Krohne Sensors

Krohne Sensor to Rosemount 8732 Transmitter

Coil Shield Coils Fuse

Rosemount Taylor Series 1100 Sensors

Taylor Sensors

Series 1100 Sensor to Rosemount 8732 Transmitter

G 1 2 3 White Black Green Coil Connections

Rosemount Taylor Sensors

Taylor Sensor to Rosemount 8732 Transmitter

S1 and S2

Coils White Black Fuse

Electrodes Chassis Ground Coils Fuse

Table E-22. Yamatake Honeywell Sensor Wiring Connections

Yamatake Honeywell Sensors

Yamatake Honeywell Sensor to Rosemount 8732 Transmitter

Rosemount Yokogawa Sensors

Table E-23. Yokogawa Sensor Wiring Connections

Yokogawa Sensors

Yokogawa Sensor to Rosemount 8732 Transmitter

Generic Manufacturer Sensors

Identify coil and electrode terminals

Identify a chassis ground

Appendix F Resource Block

Definition

Parameters and Descriptions

Confirmtime

Itkver

Rsstate

Modes

Resource Block Errors

Status Handling

Alarm Detection

Refer to Table F-4to troubleshoot resource block problems

Table F-4. Troubleshooting

Appendix G Transducer Block

SignalRanging Conversion Units Diagnostics Damping Flow

Densityvalue

Parameter Index Number Definition

User-Defined Sensor Line Size

FLOW-SPECIFIC Block Configuration Values

Table G-2. Supported Line Sizes

Table G-3. Supported Engineering Units

Condition Name and Description

Transducer Block Errors

Value Name and Description Corrective Action

Transducer Block Diagnostics

Alarm Detection Status Handling

Descriptions and Corrective Actions

Table G-6. Troubleshooting

Refer to Table G-6to troubleshoot transducer block problems

Handheld Communicator

Appendix H 375 Field Communicator Operation

Irda Port Fieldbus Connection Ports Field Communicator Ports

Connections and Hardware

ON/OFF Key

Action Keys

Function Keys, and Alphanumeric and Shift Keys

Action Keys

Data Entry

Alphanumeric and Shift Keys

Menus and Functions

Function Key

Online Menu

Main Menu

Message Description

Diagnostic Messages

OFF KEY Disabled

Rosemount

Field Wiring Electrical

Installation -6,2-12

Wiring

Basic Setup -6,3-7

Flowtube

Safety

Troubleshooting . . . . . . . F-6

Mounting

Page

Rosemount Divison

Flow Pacific Private Limited

Emerson FZE

![]() See ”Safety Messages” on pages

See ”Safety Messages” on pages