FARGO Electronics Inc.

Begin by selecting either

Next, apply a strip of ½” (12mm) wide

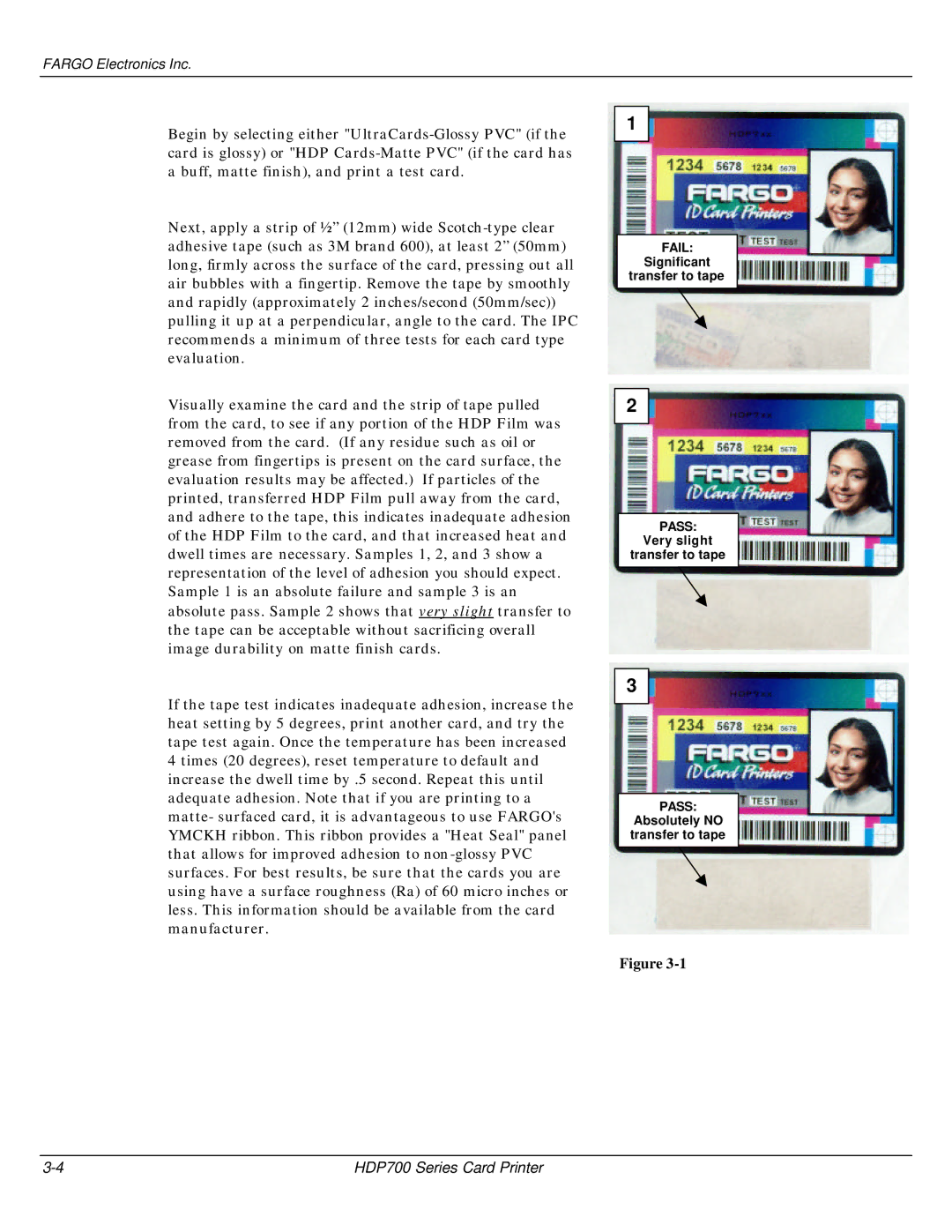

Visually examine the card and the strip of tape pulled from the card, to see if any portion of the HDP Film was removed from the card. (If any residue such as oil or grease from fingertips is present on the card surface, the evaluation results may be affected.) If particles of the printed, transferred HDP Film pull away from the card, and adhere to the tape, this indicates inadequate adhesion of the HDP Film to the card, and that increased heat and dwell times are necessary. Samples 1, 2, and 3 show a representation of the level of adhesion you should expect. Sample 1 is an absolute failure and sample 3 is an absolute pass. Sample 2 shows that very slight transfer to the tape can be acceptable without sacrificing overall image durability on matte finish cards.

If the tape test indicates inadequate adhesion, increase the heat setting by 5 degrees, print another card, and try the tape test again. Once the temperature has been increased 4 times (20 degrees), reset temperature to default and increase the dwell time by .5 second. Repeat this until adequate adhesion. Note that if you are printing to a matte- surfaced card, it is advantageous to use FARGO's YMCKH ribbon. This ribbon provides a "Heat Seal" panel that allows for improved adhesion to

1

FAIL:

Significant transfer to tape

2

PASS:

Very slight

transfer to tape

3

PASS:

Absolutely NO transfer to tape

Figure

HDP700 Series Card Printer |