Understanding paper and specialty media guidelines

•Do not use paper that has been cut or trimmed by hand.

•Do not mix media sizes, weights, or types in the same source; mixing results in jams.

•Do not use coated papers unless they are specifically designed for electrophotographic printing.

•Do not forget to change the Paper Size setting when using a source that does not support auto size sensing.

•Do not remove trays while a job is printing or Busy appears on the operator panel.

•Make sure the Paper Type, Paper Texture, and Paper Weight settings are correct. (See “Paper Menu” in the Menus and Messages Guide located on the Software and Documentation CD for detailed information about these settings.)

•Make sure the paper is properly loaded in the source.

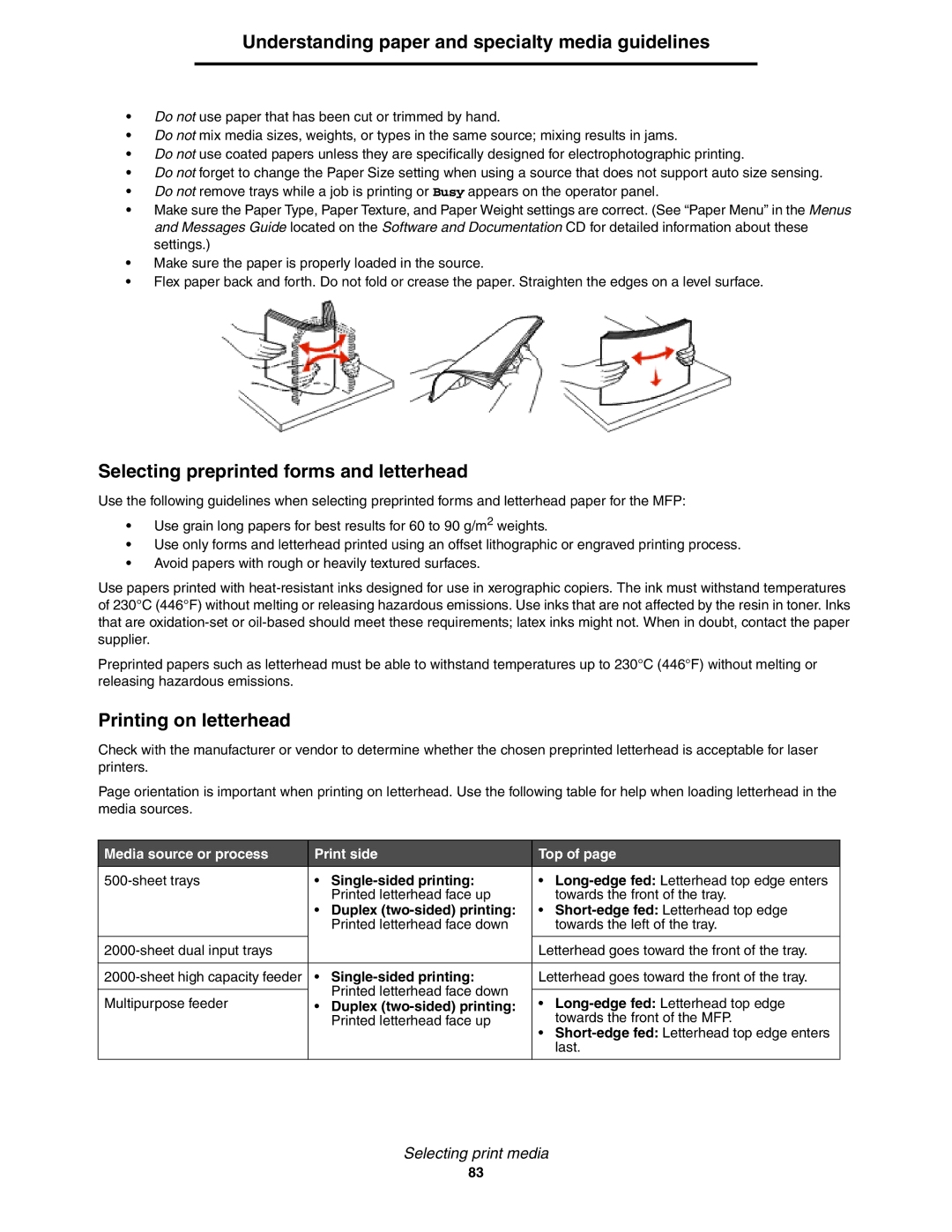

•Flex paper back and forth. Do not fold or crease the paper. Straighten the edges on a level surface.

Selecting preprinted forms and letterhead

Use the following guidelines when selecting preprinted forms and letterhead paper for the MFP:

•Use grain long papers for best results for 60 to 90 g/m2 weights.

•Use only forms and letterhead printed using an offset lithographic or engraved printing process.

•Avoid papers with rough or heavily textured surfaces.

Use papers printed with

Preprinted papers such as letterhead must be able to withstand temperatures up to 230°C (446°F) without melting or releasing hazardous emissions.

Printing on letterhead

Check with the manufacturer or vendor to determine whether the chosen preprinted letterhead is acceptable for laser printers.

Page orientation is important when printing on letterhead. Use the following table for help when loading letterhead in the media sources.

Media source or process | Print side | Top of page | |

• |

| • | |

|

| Printed letterhead face up | towards the front of the tray. |

| • | Duplex | • |

|

| Printed letterhead face down | towards the left of the tray. |

|

|

|

|

|

| Letterhead goes toward the front of the tray. | |

|

|

|

|

• | Letterhead goes toward the front of the tray. | ||

|

| Printed letterhead face down |

|

Multipurpose feeder |

| • | |

• | Duplex | ||

|

| Printed letterhead face up | towards the front of the MFP. |

|

|

| • |

|

|

| last. |

|

|

|

|

Selecting print media

83