A-4 INSTALLATIONA-4

TOC

SAFETY PRECAUTION

ELECTRIC SHOCK can kill.

CAUTION

Return to Master

•Only qualified personnel should perform this installation.

•Turn off the input power to the power source at the disconnect switch or fuse box before working on this equipment. Turn off the input power to any other equipment connected to the welding system at the disconnect switch or fuse box before working on this equipment.

•Do not touch electrically hot parts.

When using an inverter type power source like the Power Waves, use the largest welding (electrode and work) cables that are practical. At least 2/0 copper wire - even if the average output current would not normally require it. When pulsing, the pulse current can reach very high levels. Voltage drops can become excessive, leading to poor welding characteristics, if undersized welding cables are used.

WELD CABLE SIZES

Return to Section TOC

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

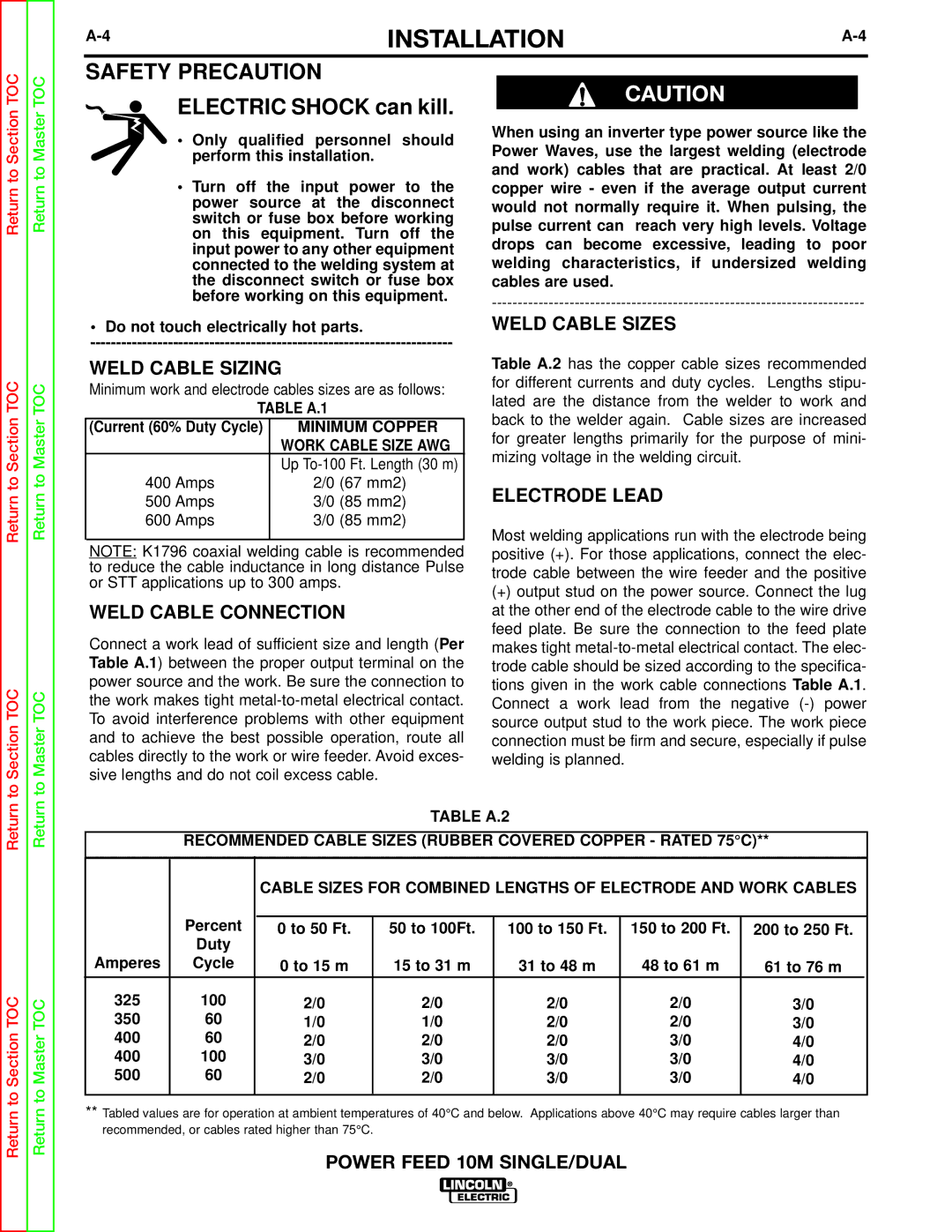

WELD CABLE SIZING

Minimum work and electrode cables sizes are as follows:

TABLE A.1

(Current (60% Duty Cycle) | MINIMUM COPPER |

| WORK CABLE SIZE AWG |

| Up |

400 Amps | 2/0 (67 mm2) |

500 Amps | 3/0 (85 mm2) |

600 Amps | 3/0 (85 mm2) |

|

|

NOTE: K1796 coaxial welding cable is recommended to reduce the cable inductance in long distance Pulse or STT applications up to 300 amps.

WELD CABLE CONNECTION

Connect a work lead of sufficient size and length (Per Table A.1) between the proper output terminal on the power source and the work. Be sure the connection to the work makes tight

Table A.2 has the copper cable sizes recommended for different currents and duty cycles. Lengths stipu- lated are the distance from the welder to work and back to the welder again. Cable sizes are increased for greater lengths primarily for the purpose of mini- mizing voltage in the welding circuit.

ELECTRODE LEAD

Most welding applications run with the electrode being positive (+). For those applications, connect the elec- trode cable between the wire feeder and the positive

(+)output stud on the power source. Connect the lug at the other end of the electrode cable to the wire drive feed plate. Be sure the connection to the feed plate makes tight

Return

Return to Section TOC

Return

Return to Master TOC

TABLE A.2

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 75°C)**

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK CABLES

| Percent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 50 to 100Ft. |

|

|

| 150 to 200 Ft. |

|

|

|

|

| |||||||

| 0 to 50 Ft. |

|

| 100 to 150 Ft. |

|

|

|

| 200 to 250 Ft. |

|

| ||||||

| Duty |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Amperes | Cycle | 0 to 15 m |

|

| 15 to 31 m |

|

| 31 to 48 m |

|

| 48 to 61 m |

|

| 61 to 76 m |

|

| |

325 | 100 |

| 2/0 |

|

| 2/0 |

|

| 2/0 |

|

| 2/0 |

|

| 3/0 |

|

|

350 | 60 |

| 1/0 |

|

| 1/0 |

|

| 2/0 |

|

| 2/0 |

|

| 3/0 |

|

|

400 | 60 |

| 2/0 |

|

| 2/0 |

|

| 2/0 |

|

| 3/0 |

|

| 4/0 |

|

|

400 | 100 |

| 3/0 |

|

| 3/0 |

|

| 3/0 |

|

| 3/0 |

|

| 4/0 |

|

|

500 | 60 |

| 2/0 |

|

| 2/0 |

|

| 3/0 |

|

| 3/0 |

|

| 4/0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

**Tabled values are for operation at ambient temperatures of 40°C and below. Applications above 40°C may require cables larger than recommended, or cables rated higher than 75°C.

POWER FEED 10M SINGLE/DUAL