OPERATION | ||

|

|

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

OVERVIEW:

The MSP4 is the standard mode select panel for the Power Feed 10M Single Wire Feeder wire feeders. The MSP4 is capable of:

-Weld mode selection.

-Arc Control adjustment.

-Weld sequence control (Preflow Time,

|

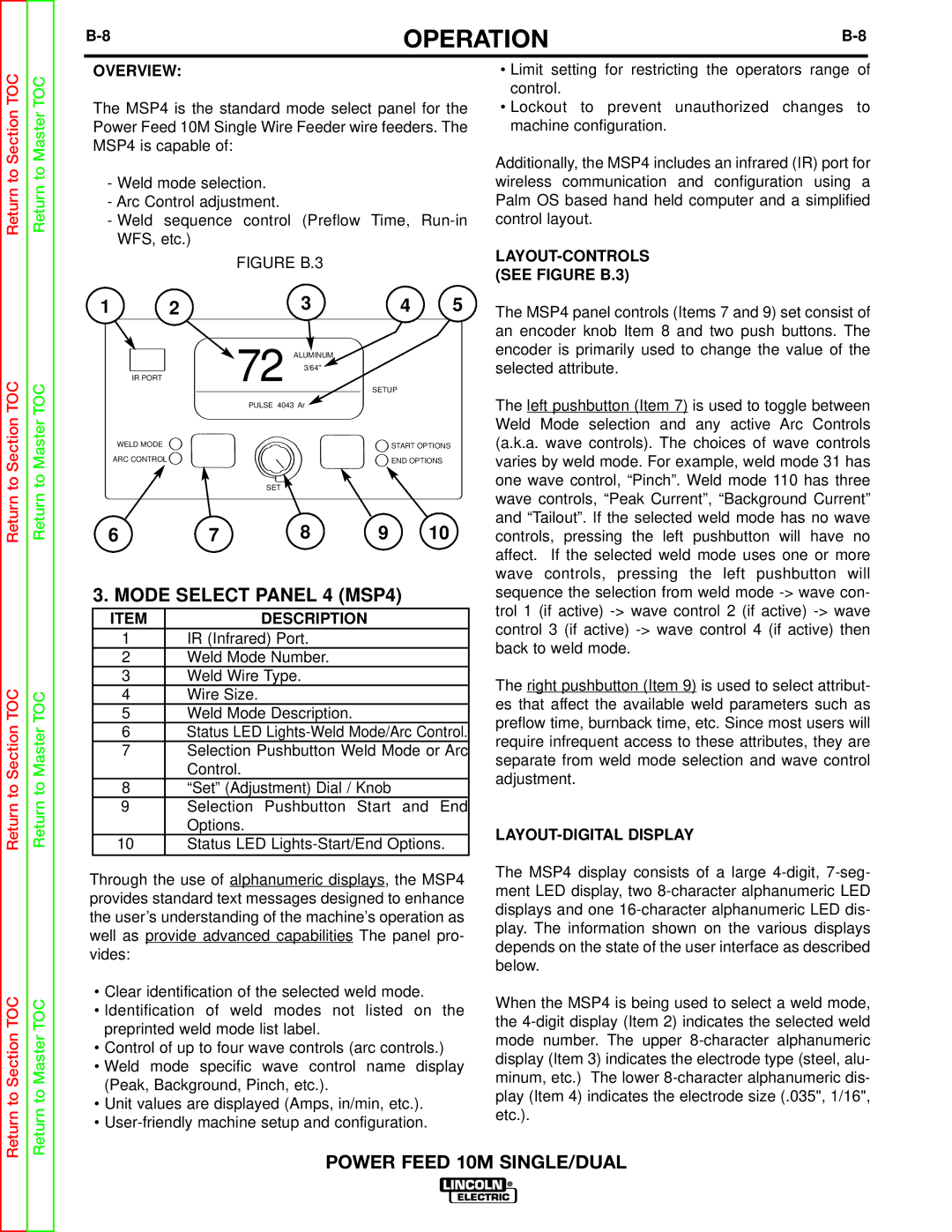

| FIGURE B.3 |

|

|

1 | 2 | 3 | 4 | 5 |

| 72 | ALUMINUM |

|

| |

|

|

| 3/64" |

|

|

IR PORT |

|

|

|

|

|

|

|

|

| SETUP | |

|

| PULSE 4043 Ar |

|

| |

WELD MODE |

|

|

|

| START OPTIONS |

ARC CONTROL |

|

|

|

| END OPTIONS |

|

| SET |

|

|

|

6 | 7 |

| 8 | 9 | 10 |

3. MODE SELECT PANEL 4 (MSP4) | |||||

ITEM |

| DESCRIPTION |

|

| |

1 | IR (Infrared) Port. |

|

| ||

2 | Weld Mode Number. |

|

| ||

3 | Weld Wire Type. |

|

| ||

4 | Wire Size. |

|

|

| |

5 | Weld Mode Description. |

|

| ||

6 | Status LED | ||||

7 | Selection Pushbutton Weld Mode or Arc | ||||

| Control. |

|

|

|

|

8 | “Set” (Adjustment) Dial / Knob |

| |||

9 | Selection Pushbutton Start and End | ||||

| Options. |

|

|

|

|

10 | Status LED | ||||

Through the use of alphanumeric displays, the MSP4 provides standard text messages designed to enhance the user’s understanding of the machine’s operation as well as provide advanced capabilities The panel pro- vides:

•Clear identification of the selected weld mode.

•Identification of weld modes not listed on the preprinted weld mode list label.

•Control of up to four wave controls (arc controls.)

•Weld mode specific wave control name display (Peak, Background, Pinch, etc.).

•Unit values are displayed (Amps, in/min, etc.).

•

•Limit setting for restricting the operators range of control.

•Lockout to prevent unauthorized changes to machine configuration.

Additionally, the MSP4 includes an infrared (IR) port for wireless communication and configuration using a Palm OS based hand held computer and a simplified control layout.

LAYOUT-CONTROLS (SEE FIGURE B.3)

The MSP4 panel controls (Items 7 and 9) set consist of an encoder knob Item 8 and two push buttons. The encoder is primarily used to change the value of the selected attribute.

The left pushbutton (Item 7) is used to toggle between Weld Mode selection and any active Arc Controls (a.k.a. wave controls). The choices of wave controls varies by weld mode. For example, weld mode 31 has one wave control, “Pinch”. Weld mode 110 has three wave controls, “Peak Current”, “Background Current” and “Tailout”. If the selected weld mode has no wave controls, pressing the left pushbutton will have no affect. If the selected weld mode uses one or more wave controls, pressing the left pushbutton will sequence the selection from weld mode

The right pushbutton (Item 9) is used to select attribut- es that affect the available weld parameters such as preflow time, burnback time, etc. Since most users will require infrequent access to these attributes, they are separate from weld mode selection and wave control adjustment.

LAYOUT-DIGITAL DISPLAY

The MSP4 display consists of a large

When the MSP4 is being used to select a weld mode, the

POWER FEED 10M SINGLE/DUAL