OPERATION | ||

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

B. VOLTS / TRIM DISPLAY AND OUTPUT KNOB

The voltage/trim meter displays either the voltage or trim value, depending upon the welding process (mode) being used and the status of the wire feeder and power source.

Below the meter are the words “Volts” and “Trim”. An LED light illuminates to designate which value is being displayed on the meter. The knob below the meter adjusts the value displayed in the meter. The following tables describe the function of the Volts / Trim display depending upon the status of the wire feeder / power source package and the welding process utilized.

PRIOR TO WELDING

Weld Process | Volts / Trim Display prior to operation | |

|

|

|

Nonsynergic CV | Displays the preset Voltage value. | |

|

|

|

Synergic CV | Displays the preset Voltage value. | |

|

|

|

Synergic | Displays the preset Trim value from 0.50 | |

to 1.50, with 1.00 as the default. Trim | ||

| adjusts the arc length for Pulse programs. | |

| Lower the trim value to decrease the arc | |

| length, and raise the trim value to increase | |

| the arc length. A trim value of 1.00 is opti- | |

| mum for most conditions. | |

|

|

|

Synergic | • Adjusts the background current of the | |

| STT waveform. Used to modify the heat | |

| input. | |

| • Linc Net Power Sources: Displays the | |

| background current as a value from 0.50 | |

| to 1.50, with 1.00 as the default. Lower | |

| the trim value to decrease the heat input, | |

| and raise the trim value to increase the | |

| heat input. A trim value of 1.00 is opti- | |

| mum for most conditions. | |

| • Arc Link Power Sources: Displays the | |

| background current in amps. Lower the | |

| background current to decrease the heat | |

| input and raise the background current to | |

| increase the heat input. | |

|

| |

Nonsynergic | Displays the preset CP value from 0 to 20. | |

Power | The Power mode is best for thin sheet | |

| metal and aluminum applications. | |

|

|

|

DURING WELDING | ||

Weld Process | Volts / Trim Display |

|

All Processes | Displays Actual |

|

| Average Arc Voltage |

|

|

|

|

AFTER WELDING

Weld Process | Volt/Trim Display |

|

|

All Processes | After welding, the meter holds the actual |

| average arc voltage for 5 seconds. During |

| this time, the display flashes to indicate |

| the wire feeder is in the "Hold" period. |

| Output adjustment while in the "Hold" |

| period results in the "prior to operation" |

| characteristics described above. |

SYNERGIC CV VOLTAGE DISPLAY

Synergic CV programs feature an ideal voltage best suited for most procedures. Use this voltage as a start- ing point for the weld procedure and adjust if needed for personal preferences.

The voltage is calibrated to ±2% over a range of 10 to 45 volts.

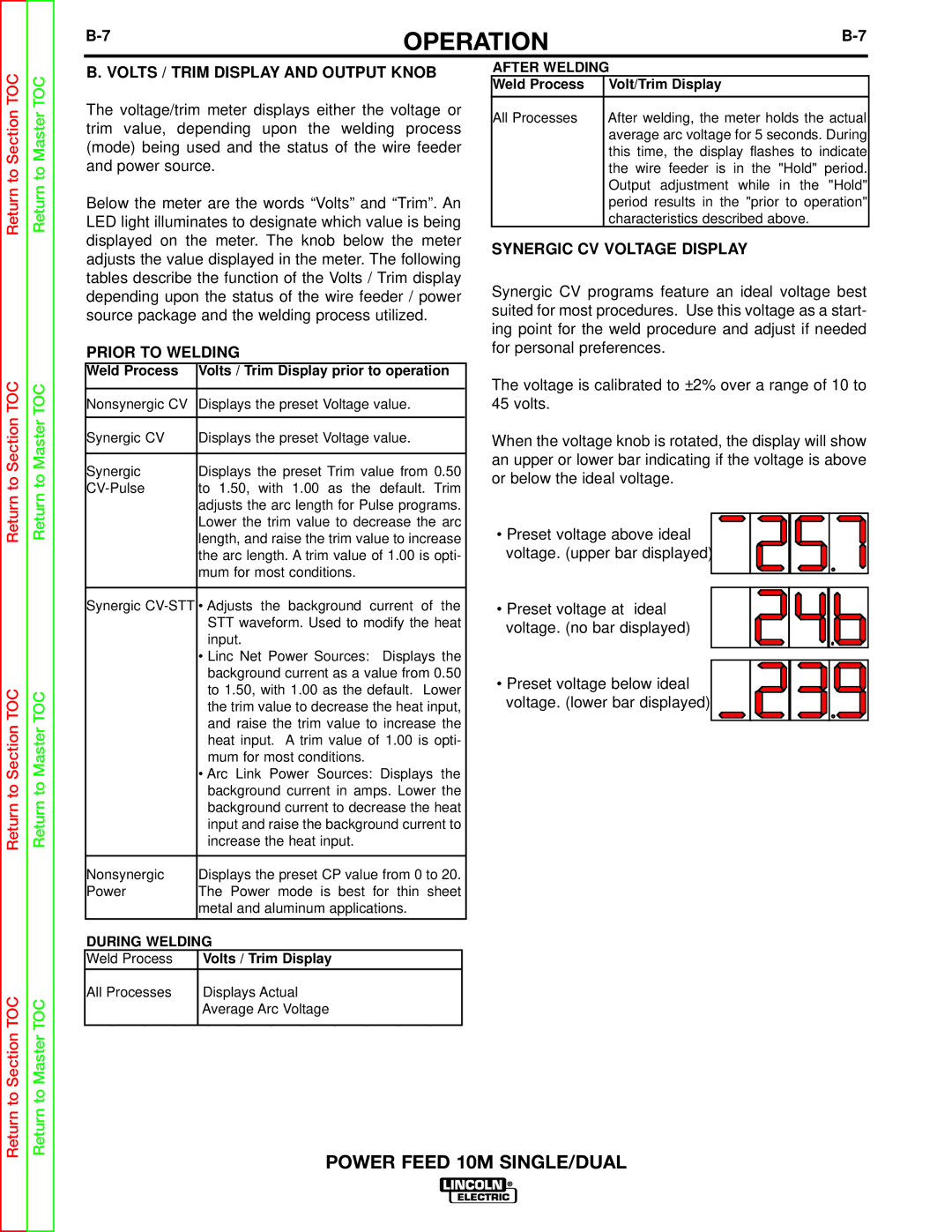

When the voltage knob is rotated, the display will show an upper or lower bar indicating if the voltage is above or below the ideal voltage.

• Preset voltage above ideal voltage. (upper bar displayed)

• Preset voltage at ideal voltage. (no bar displayed)

• Preset voltage below ideal voltage. (lower bar displayed)

POWER FEED 10M SINGLE/DUAL