to Section TOC

to Master TOC

INSTALLATION | ||

|

|

|

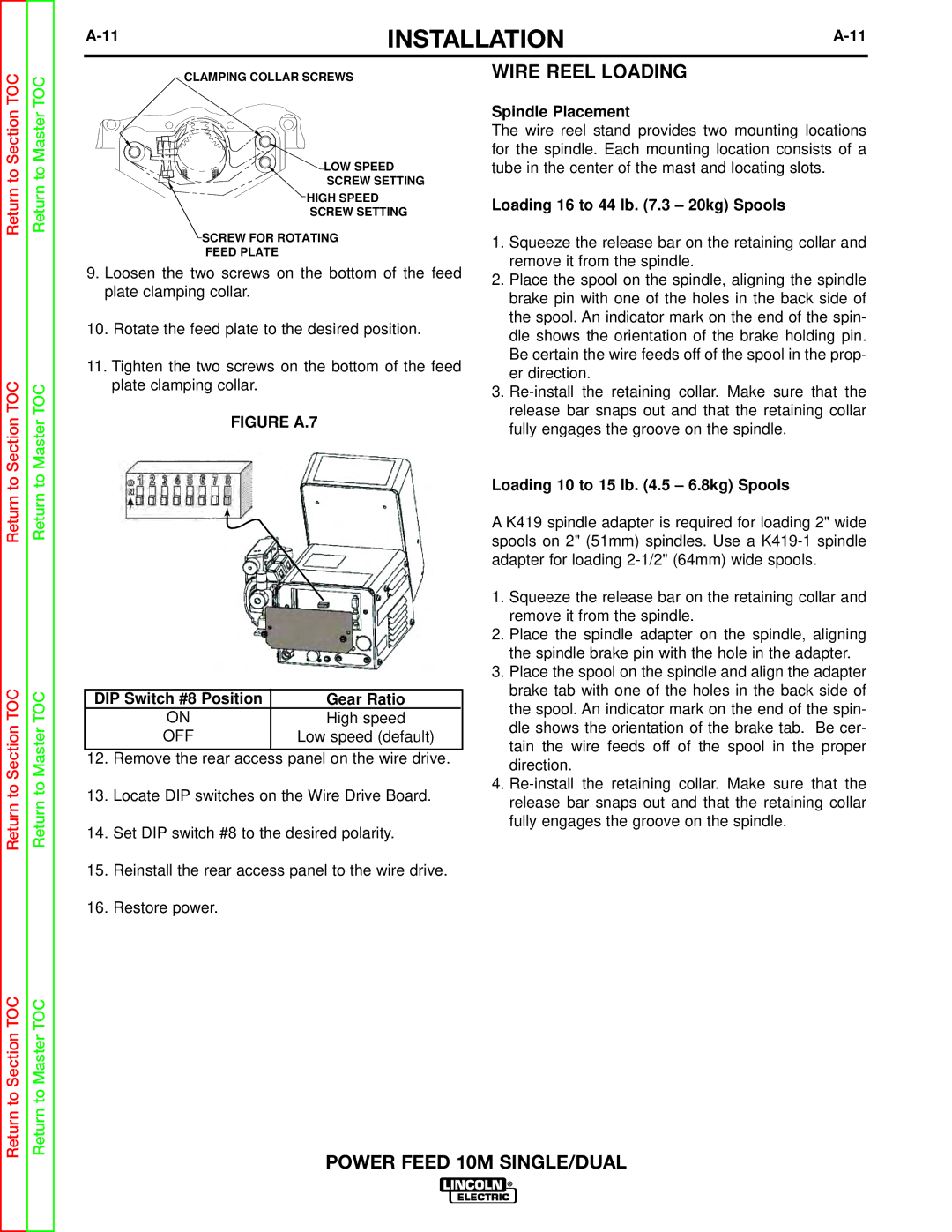

CLAMPING COLLAR SCREWS | WIRE REEL LOADING |

|

| Spindle Placement |

| The wire reel stand provides two mounting locations |

| for the spindle. Each mounting location consists of a |

LOW SPEED | tube in the center of the mast and locating slots. |

SCREW SETTING |

|

Return

Return to Section TOC

Return to Section TOC

Return

Return to Master TOC

Return to Master TOC

HIGH SPEED

SCREW SETTING

SCREW FOR ROTATING

FEED PLATE

9.Loosen the two screws on the bottom of the feed plate clamping collar.

10.Rotate the feed plate to the desired position.

11.Tighten the two screws on the bottom of the feed plate clamping collar.

FIGURE A.7

| DIP Switch #8 Position |

|

| Gear Ratio |

|

| ON |

|

| High speed |

|

| OFF |

|

| Low speed (default) |

|

|

|

|

|

|

|

12.Remove the rear access panel on the wire drive.

13.Locate DIP switches on the Wire Drive Board.

14.Set DIP switch #8 to the desired polarity.

Loading 16 to 44 lb. (7.3 – 20kg) Spools

1.Squeeze the release bar on the retaining collar and remove it from the spindle.

2.Place the spool on the spindle, aligning the spindle brake pin with one of the holes in the back side of the spool. An indicator mark on the end of the spin- dle shows the orientation of the brake holding pin. Be certain the wire feeds off of the spool in the prop- er direction.

3.

Loading 10 to 15 lb. (4.5 – 6.8kg) Spools

A K419 spindle adapter is required for loading 2" wide spools on 2" (51mm) spindles. Use a

1.Squeeze the release bar on the retaining collar and remove it from the spindle.

2.Place the spindle adapter on the spindle, aligning the spindle brake pin with the hole in the adapter.

3.Place the spool on the spindle and align the adapter brake tab with one of the holes in the back side of the spool. An indicator mark on the end of the spin- dle shows the orientation of the brake tab. Be cer- tain the wire feeds off of the spool in the proper direction.

4.

Return to Section TOC

Return to Master TOC

15.Reinstall the rear access panel to the wire drive.

16.Restore power.

POWER FEED 10M SINGLE/DUAL