Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

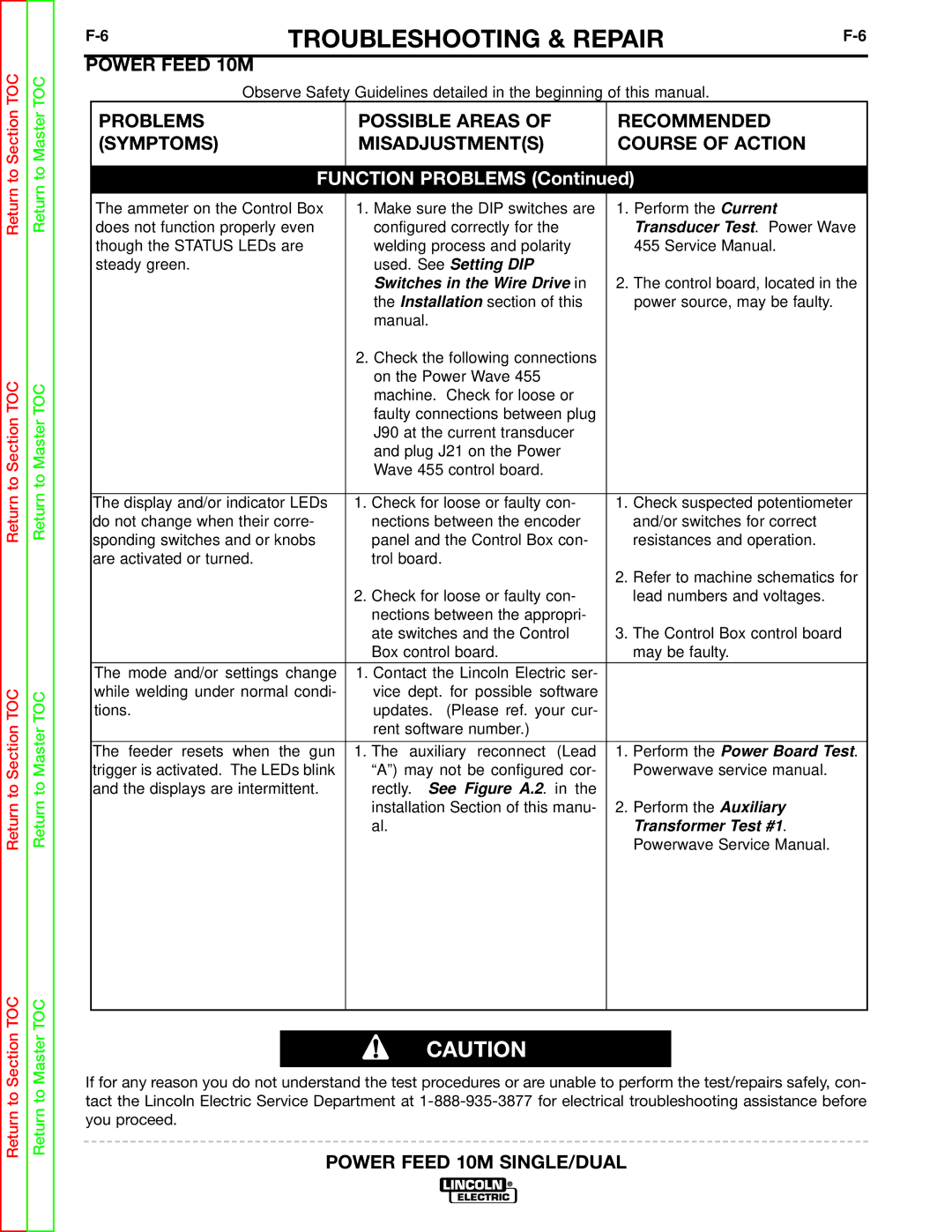

TROUBLESHOOTING & REPAIR | |||||

|

|

|

|

|

|

POWER FEED 10M |

|

|

|

| |

| Observe Safety Guidelines detailed in the beginning of this manual. |

| |||

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

|

|

|

|

|

| FUNCTION PROBLEMS (Continued) |

| ||

|

|

|

|

| |

| The ammeter on the Control Box | 1. Make sure the DIP switches are | 1. Perform the Current |

| |

| does not function properly even | configured correctly for the | Transducer Test. Power Wave | ||

| though the STATUS LEDs are | welding process and polarity | 455 Service Manual. |

| |

| steady green. |

| used. See Setting DIP |

|

|

|

|

| Switches in the Wire Drive in | 2. The control board, located in the | |

|

|

| the Installation section of this | power source, may be faulty. |

|

|

|

| manual. |

|

|

|

|

| 2. Check the following connections |

|

|

|

|

| on the Power Wave 455 |

|

|

|

|

| machine. Check for loose or |

|

|

|

|

| faulty connections between plug |

|

|

|

|

| J90 at the current transducer |

|

|

|

|

| and plug J21 on the Power |

|

|

|

|

| Wave 455 control board. |

|

|

|

|

|

| ||

| The display and/or indicator LEDs | 1. Check for loose or faulty con- | 1. Check suspected potentiometer | ||

| do not change when their corre- | nections between the encoder | and/or switches for correct |

| |

| sponding switches and or knobs | panel and the Control Box con- | resistances and operation. |

| |

| are activated or turned. |

| trol board. |

|

|

|

|

|

| 2. Refer to machine schematics for | |

|

|

| 2. Check for loose or faulty con- | lead numbers and voltages. |

|

|

|

| nections between the appropri- |

|

|

|

|

| ate switches and the Control | 3. The Control Box control board |

|

|

|

| Box control board. | may be faulty. |

|

|

|

|

|

| |

| The mode and/or settings change | 1. Contact the Lincoln Electric ser- |

|

| |

| while welding under normal condi- | vice dept. for possible software |

|

| |

| tions. |

| updates. (Please ref. your cur- |

|

|

|

|

| rent software number.) |

|

|

|

|

|

| ||

| The feeder resets when the gun | 1. The auxiliary reconnect (Lead | 1. Perform the Power Board Test. | ||

| trigger is activated. The LEDs blink | “A”) may not be configured cor- | Powerwave service manual. |

| |

| and the displays are intermittent. | rectly. See Figure A.2. in the |

|

| |

|

|

| installation Section of this manu- | 2. Perform the Auxiliary |

|

|

|

| al. | Transformer Test #1. |

|

|

|

|

| Powerwave Service Manual. |

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department at