Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

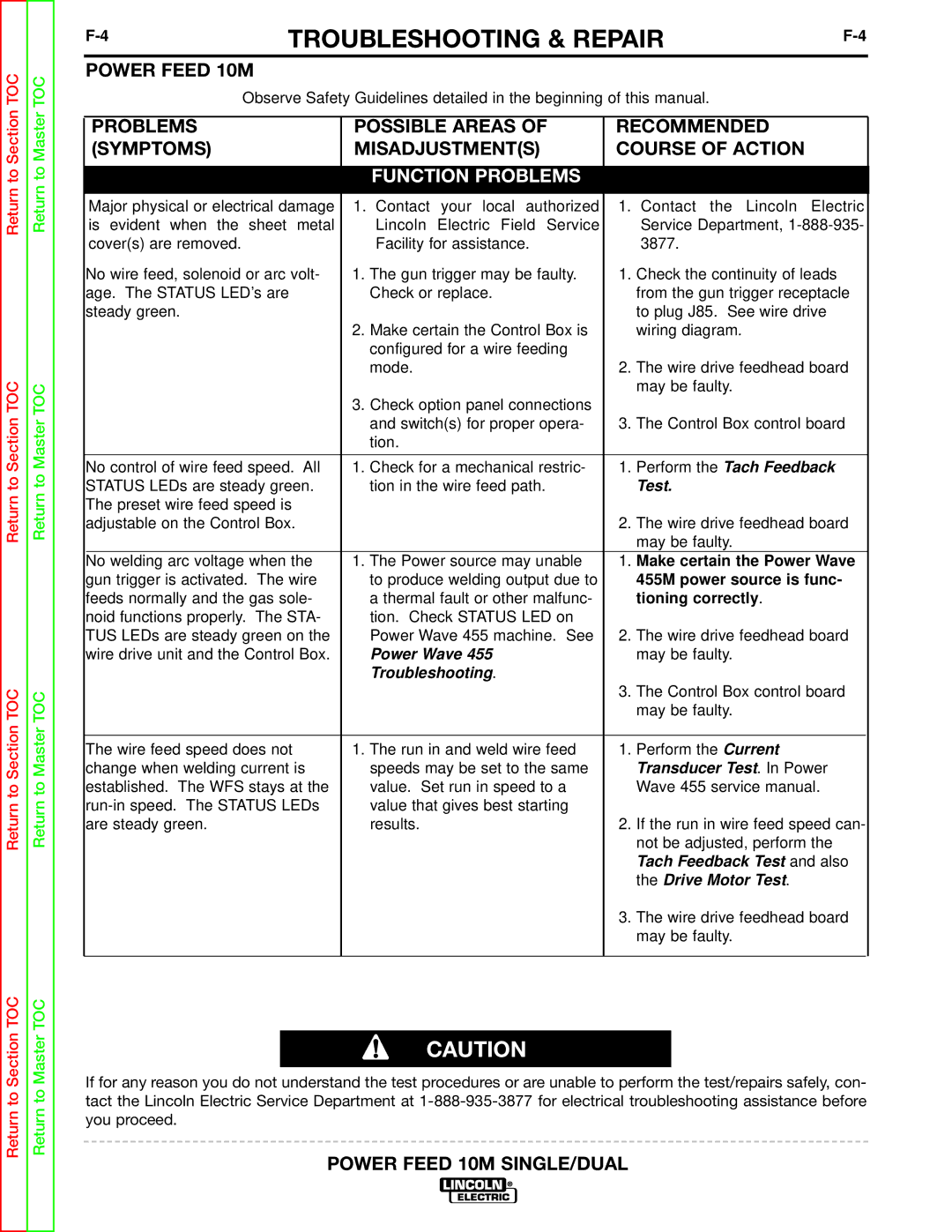

TROUBLESHOOTING & REPAIR |

POWER FEED 10M

Observe Safety Guidelines detailed in the beginning of this manual.

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

|

|

|

|

| Major physical or electrical damage | 1. Contact your local authorized | 1. | Contact the Lincoln Electric |

| is evident when the sheet metal | Lincoln Electric Field Service |

| Service Department, |

| cover(s) are removed. | Facility for assistance. |

| 3877. |

No wire feed, solenoid or arc volt- | 1. The gun trigger may be faulty. | 1. | Check the continuity of leads | |

age. The STATUS LED’s are | Check or replace. |

| from the gun trigger receptacle | |

steady green. |

|

| to plug J85. See wire drive | |

|

| 2. Make certain the Control Box is |

| wiring diagram. |

|

| configured for a wire feeding |

|

|

|

| mode. | 2. | The wire drive feedhead board |

|

|

|

| may be faulty. |

|

| 3. Check option panel connections |

|

|

|

| and switch(s) for proper opera- | 3. | The Control Box control board |

|

| tion. |

|

|

|

|

|

|

|

No control of wire feed speed. All | 1. Check for a mechanical restric- | 1. | Perform the Tach Feedback | |

STATUS LEDs are steady green. | tion in the wire feed path. |

| Test. | |

The preset wire feed speed is |

|

|

| |

adjustable on the Control Box. |

| 2. | The wire drive feedhead board | |

|

|

|

| may be faulty. |

| No welding arc voltage when the | 1. The Power source may unable | 1. | Make certain the Power Wave |

gun trigger is activated. The wire | to produce welding output due to |

| 455M power source is func- | |

feeds normally and the gas sole- | a thermal fault or other malfunc- |

| tioning correctly. | |

noid functions properly. The STA- | tion. Check STATUS LED on |

|

| |

TUS LEDs are steady green on the | Power Wave 455 machine. See | 2. | The wire drive feedhead board | |

wire drive unit and the Control Box. | Power Wave 455 |

| may be faulty. | |

|

| Troubleshooting. |

|

|

|

|

| 3. | The Control Box control board |

|

|

|

| may be faulty. |

|

|

|

| |

The wire feed speed does not | 1. The run in and weld wire feed | 1. | Perform the Current | |

change when welding current is | speeds may be set to the same |

| Transducer Test. In Power | |

established. The WFS stays at the | value. Set run in speed to a |

| Wave 455 service manual. | |

value that gives best starting |

|

| ||

are steady green. | results. | 2. | If the run in wire feed speed can- | |

|

|

|

| not be adjusted, perform the |

|

|

|

| Tach Feedback Test and also |

|

|

|

| the Drive Motor Test. |

|

|

| 3. | The wire drive feedhead board |

|

|

|

| may be faulty. |

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department at