INSTALLATION | ||

|

|

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

CHANGING THE WIRE DRIVE GEAR RATIO

Changing the ratio requires a gear and a dip switch setting change. The Power Feed Wire Feeders are shipped with both high speed and a low speed gears. As shipped from the factory, the low speed (high torque) gear is installed on the feeder. For identification purposes, the low speed (high torque) gear has 20 teeth and is 1.1 inches in diameter. The high speed gear has 30 teeth and is 1.6 inches in diameter.

![]() WARNING

WARNING

Power down the Power Feed 10M Dual Wire Feeder by turning off its companion Power Wave power source. For maximum safety, disconnect the con- trol cable from the Power Feed 10M Dual Wire Feeder.

GEAR RATIO CHANGE PROCEDURE:

1.Pull open the Wire Drive Door.

2.Remove the Phillips head screw retaining the pin- ion gear to be changed and remove the gear. If the gear is not easily accessible or difficult to remove, remove the feed plate from the gearbox. To remove feed plate:

a.Loosen the clamping collar screw using a 3/16" Allen wrench. The clamping collar screw is accessed from the bottom of the feed plate. It is the screw which is perpendicular to the feeding direction.

b.Loosen the retaining screw, which is also accessed from bottom of feeder, using a 3/16" Allen wrench. Continue to loosen the screw until the feed plate can be easily pulled off of the wire feeder.

3.Loosen, but do not remove, the screw on the lower right face of the feed plate with a 3/16" Allen wrench.

4.Remove the screw on the left face of the feed plate. If changing from high speed (larger gear) to low speed (smaller gear), line the lower hole on the left face of the feed plate with the threads on the clamping collar. Line the upper hole with the threads to install larger gear for high speed feeder. If feed plate does not rotate to allow holes to line up, further loosen the screw on right face of feed plate.

5.Remove the small gear from the output shaft. Lightly cover the output shaft with engine oil or equivalent. Install gear onto output shaft and secure with flat washer, lock washer, and Phillips head screw which were previously removed.

6.Tighten the screw on lower right face of feed plate.

7.

8.Feed plate will be rotated

9.Set the wire drive gear ratio switch on Wire Drive PC board as follows:

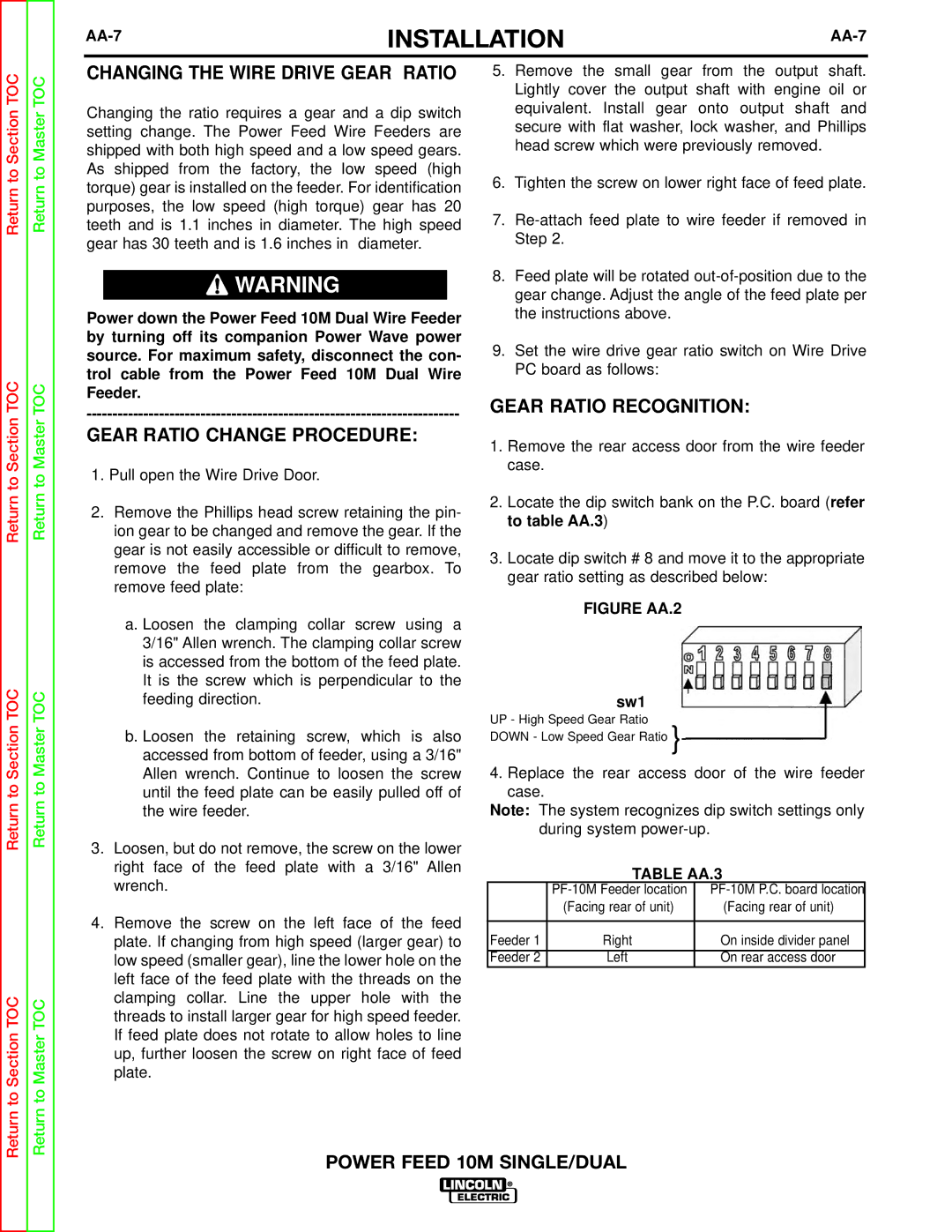

GEAR RATIO RECOGNITION:

1.Remove the rear access door from the wire feeder case.

2.Locate the dip switch bank on the P.C. board (refer to table AA.3)

3.Locate dip switch # 8 and move it to the appropriate gear ratio setting as described below:

FIGURE AA.2

sw1

UP - High Speed Gear Ratio

DOWN - Low Speed Gear Ratio }

4.Replace the rear access door of the wire feeder case.

Note: The system recognizes dip switch settings only during system

TABLE AA.3

| ||

| (Facing rear of unit) | (Facing rear of unit) |

|

|

|

Feeder 1 | Right | On inside divider panel |

Feeder 2 | Left | On rear access door |