Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

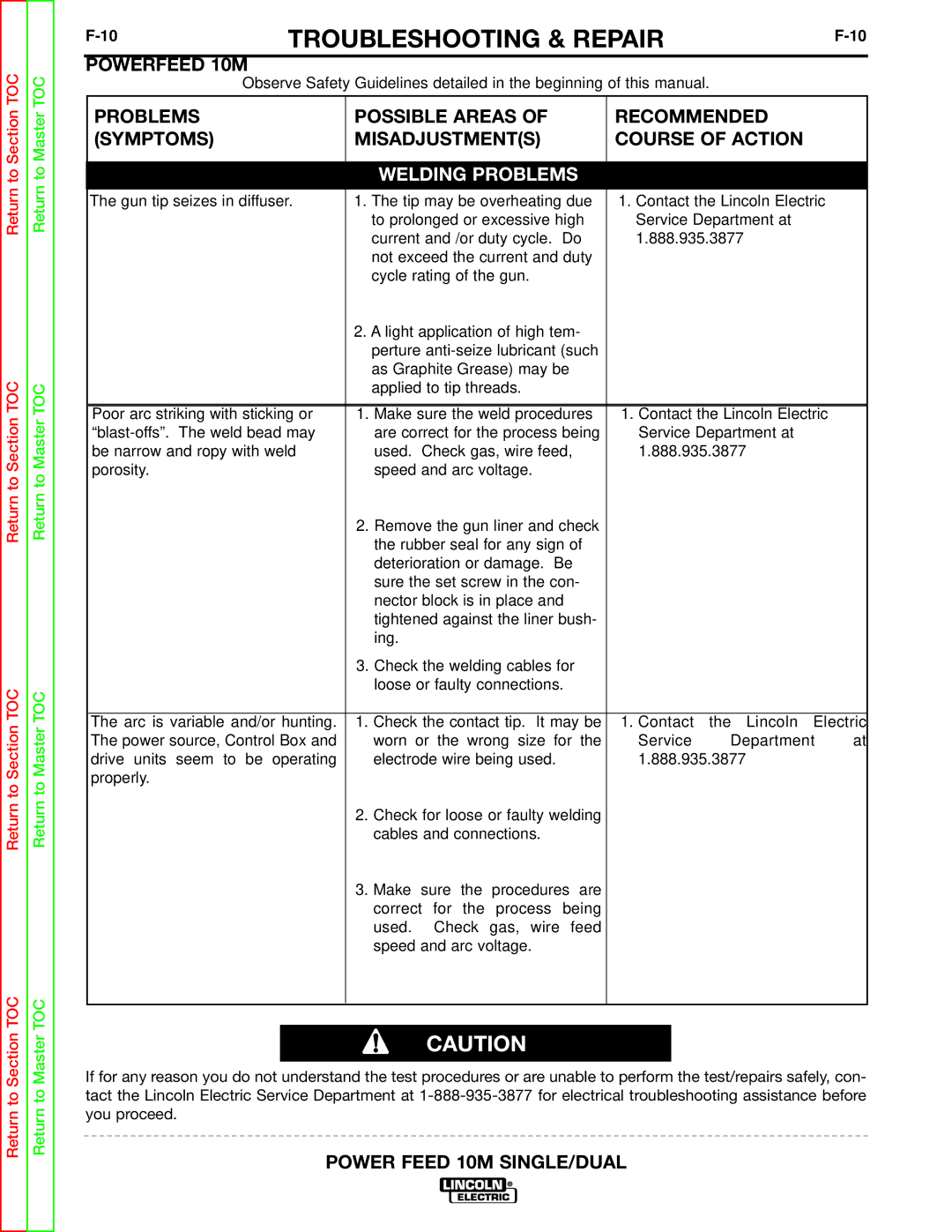

TROUBLESHOOTING & REPAIR |

| |||||

|

|

|

|

|

| |

POWERFEED 10M |

|

|

|

| ||

|

| Observe Safety Guidelines detailed in the beginning of this manual. |

| |||

|

|

|

|

|

| |

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

| |

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| |

|

|

|

|

|

|

|

|

|

| WELDING PROBLEMS |

|

|

|

|

|

|

|

| ||

| The gun tip seizes in diffuser. | 1. The tip may be overheating due | 1. Contact the Lincoln Electric |

| ||

|

|

| to prolonged or excessive high | Service Department at |

| |

|

|

| current and /or duty cycle. Do | 1.888.935.3877 |

| |

|

|

| not exceed the current and duty |

|

|

|

|

|

| cycle rating of the gun. |

|

|

|

|

|

| 2. A light application of high tem- |

|

|

|

|

|

| perture |

|

|

|

|

|

| as Graphite Grease) may be |

|

|

|

|

|

| applied to tip threads. |

|

|

|

|

|

|

|

| ||

| Poor arc striking with sticking or | 1. Make sure the weld procedures | 1. Contact the Lincoln Electric |

| ||

| are correct for the process being | Service Department at |

| |||

| be narrow and ropy with weld | used. Check gas, wire feed, | 1.888.935.3877 |

| ||

| porosity. |

| speed and arc voltage. |

|

|

|

|

|

| 2. Remove the gun liner and check |

|

|

|

|

|

| the rubber seal for any sign of |

|

|

|

|

|

| deterioration or damage. Be |

|

|

|

|

|

| sure the set screw in the con- |

|

|

|

|

|

| nector block is in place and |

|

|

|

|

|

| tightened against the liner bush- |

|

|

|

|

|

| ing. |

|

|

|

|

|

| 3. Check the welding cables for |

|

|

|

|

|

| loose or faulty connections. |

|

|

|

|

|

|

|

| ||

| The arc is variable and/or hunting. | 1. Check the contact tip. It may be | 1. Contact | the Lincoln Electric | ||

| The power source, Control Box and | worn or the wrong size for the | Service | Department | at | |

| drive units seem to be operating | electrode wire being used. | 1.888.935.3877 |

| ||

| properly. |

|

|

|

|

|

|

|

| 2. Check for loose or faulty welding |

|

|

|

|

|

| cables and connections. |

|

|

|

|

|

| 3. Make sure the procedures are |

|

|

|

|

|

| correct for the process being |

|

|

|

|

|

| used. Check gas, wire feed |

|

|

|

|

|

| speed and arc voltage. |

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department at