| INSTALLATION | |

|

|

|

Return to Master TOC

TOC

Work Voltage Sensing

The standard Power Wave 455’s default to the work stud (work sense lead disabled)

For processes requiring work voltage sensing, connect the (21) work voltage sense lead (K940) from the Power Wave work sense lead receptacle to the work piece. Attach the sense lead to the work piece as close to the weld as practical, but not in the return current path. Enable the work voltage sensing in the Power Wave as follows:

![]() WARNING

WARNING

•Do not touch electrically live parts or electrodes with your skin or wet clothing.

•Insulate yourself from the work and ground.

WIRE DRIVE GEAR RATIO (HIGH OR LOW SPEED)

The speed range capability and drive torque of the Power Feed wire drives can be easily and quickly changed by changing the external drive gear. The Power Feed Wire Feeders are shipped with both high speed and a low speed gears. As shipped from the fac- tory, the low speed (high torque) gear is installed on the feeder. If this is the desired gear ratio, no changes need be made.

If a change in gear ratio is desired, the systems needs to be made aware of which gear has been installed on the Wire Drive, low or high speed. This is accom- plished through the selection of a dip switch on the wire drive PCB.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master

Return to Master TOC

•Always wear dry insulating gloves.

1.Turn off power to the power source at the disconnect switch.

2.Remove the front cover from the power source.

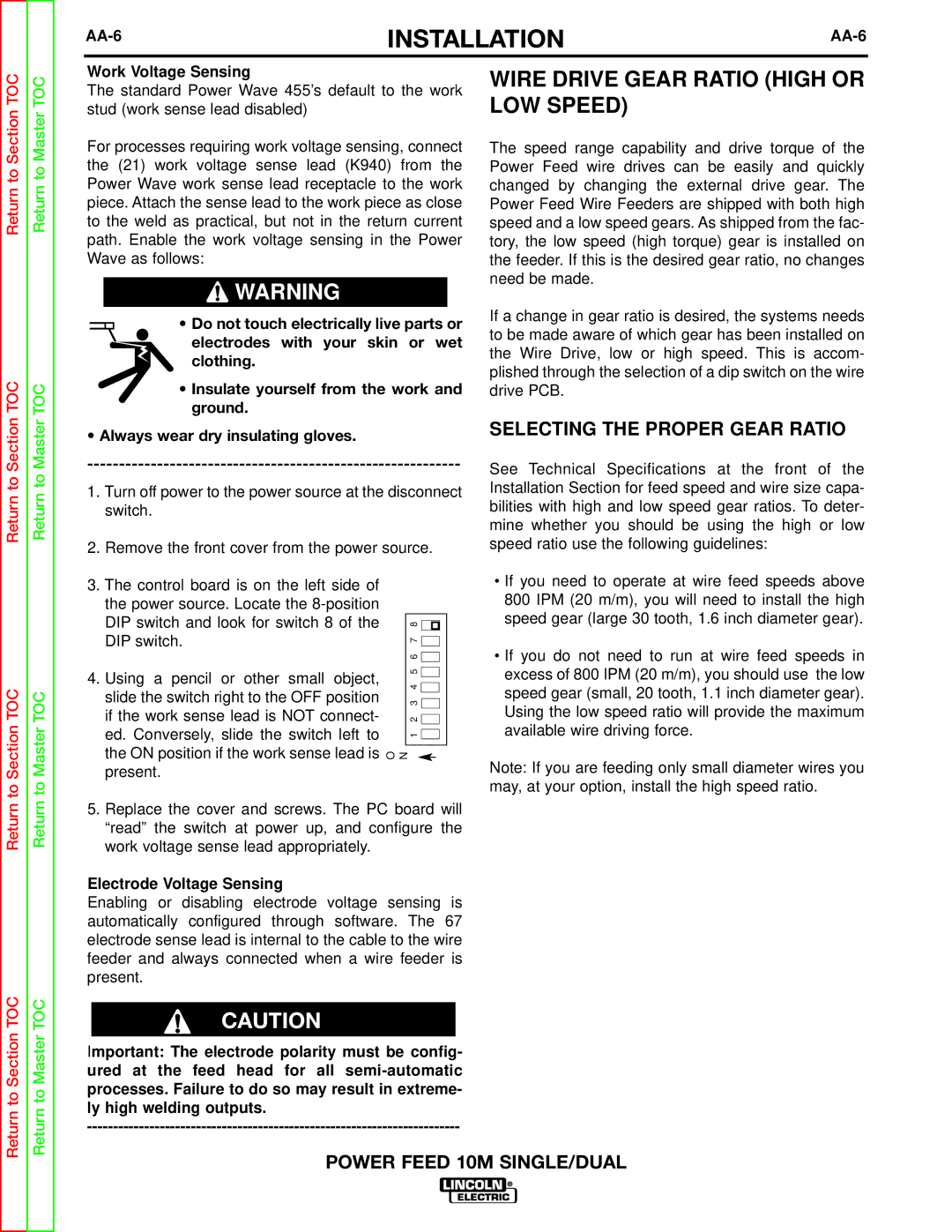

3.The control board is on the left side of the power source. Locate the

DIP switch and look for switch 8 of the |

|

| 8 |

|

|

|

DIP switch. |

|

| 7 |

|

|

|

|

|

| 6 |

|

|

|

4. Using a pencil or other small object, |

|

| 5 |

|

|

|

|

| 3 4 |

|

|

| |

slide the switch right to the OFF position |

|

|

|

|

| |

if the work sense lead is NOT connect- |

|

| 2 |

|

|

|

ed. Conversely, slide the switch left to |

|

| 1 |

|

|

|

the ON position if the work sense lead is |

|

|

|

|

|

|

|

|

|

|

|

| |

O N |

|

| ||||

| ||||||

present. |

|

|

|

|

|

|

5.Replace the cover and screws. The PC board will “read” the switch at power up, and configure the work voltage sense lead appropriately.

Electrode Voltage Sensing

Enabling or disabling electrode voltage sensing is automatically configured through software. The 67 electrode sense lead is internal to the cable to the wire feeder and always connected when a wire feeder is present.

SELECTING THE PROPER GEAR RATIO

See Technical Specifications at the front of the Installation Section for feed speed and wire size capa- bilities with high and low speed gear ratios. To deter- mine whether you should be using the high or low speed ratio use the following guidelines:

•If you need to operate at wire feed speeds above 800 IPM (20 m/m), you will need to install the high speed gear (large 30 tooth, 1.6 inch diameter gear).

•If you do not need to run at wire feed speeds in excess of 800 IPM (20 m/m), you should use the low speed gear (small, 20 tooth, 1.1 inch diameter gear). Using the low speed ratio will provide the maximum available wire driving force.

Note: If you are feeding only small diameter wires you may, at your option, install the high speed ratio.

Return to Section TOC

Return to Master TOC

![]() CAUTION

CAUTION

Important: The electrode polarity must be config- ured at the feed head for all