Return to Section TOC

Return to Master TOC

INSTALLATION | ||

|

| |

WIRE FEED SHUT DOWN CIRCUIT |

| |

The wire feed shut down circuit is used to stop the wire feed in the event of a fault. The most common use of the circuit is with water cooled guns. A flow sensor is connected to the circuit to protect the welding gun if the water flow is interrupted.

The Power Feed 10M Single Wire Feeder has two leads, 570A and 570B, located inside the wire drive that are electrically common. If flow switch is used, separate these leads and connect to normally closed flow switch terminals when water is flowing. Connect the flow sensor to these two leads.

CHANGING THE GEAR RATIO

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

The Power Feed 10M Single Wire Feeder wire drive may be configured for either low speed or high speed, depending upon the application. The wire feeders are factory assembled for low speed operation and include a gear for high speed operation.

|

|

|

|

|

|

|

|

|

| |

Gear |

|

|

| Wire Size |

| |||||

Purpose: |

|

|

| |||||||

Speed | ||||||||||

Ratio |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| Solid | Core | |||

|

|

|

|

|

|

|

|

| ||

| Best | for | most |

|

|

|

|

| ||

| GMAW and FCAW |

|

|

|

|

| ||||

| welding. The | low |

|

|

|

|

| |||

Low Speed | speed | gear | ratio | .035 | ||||||

provides | the | most | ||||||||

| force | for | pushing | (0.6 - 2.4 mm) | (0.9 - 3.0 | |||||

|

|

|

| mm) | ||||||

| wires through long |

|

|

| ||||||

|

|

|

|

|

| |||||

| guns | or | pulling |

|

|

|

|

| ||

| wire through | con- |

|

|

|

|

| |||

| duits. |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| ||||

High Speed | Suitable | only for |

|

| ||||||

| small |

| diameter | .(0.6 - 1.6 mm) | .035 - 5/64 in. | |||||

| wires | operating at |

|

|

| (0.9 - 2.0 | ||||

| high | wire | feed |

|

|

| ||||

|

|

|

| mm) | ||||||

| speeds. | Feeding |

|

|

| |||||

|

|

|

|

|

| |||||

| force is less. |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

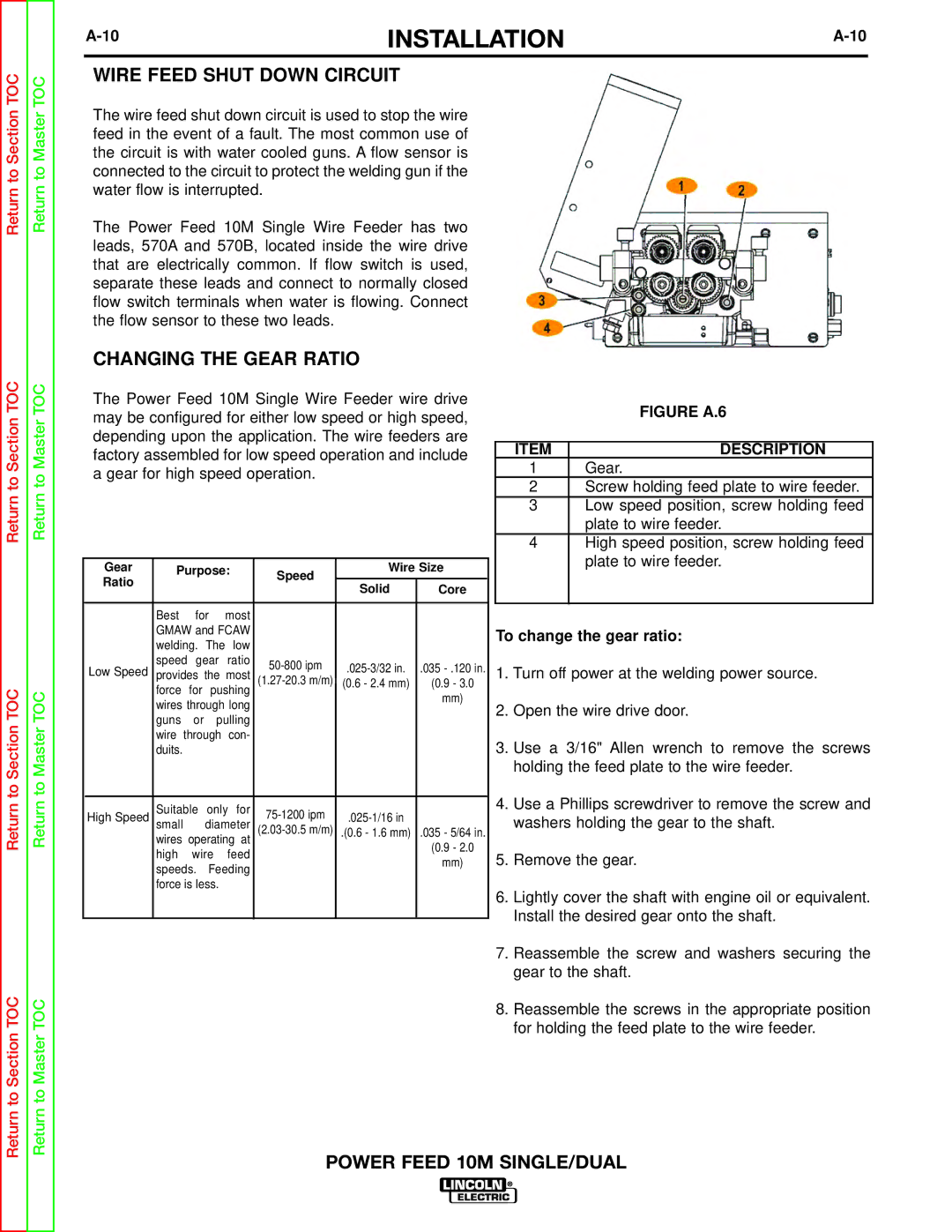

FIGURE A.6

ITEM | DESCRIPTION |

1Gear.

2Screw holding feed plate to wire feeder.

3Low speed position, screw holding feed plate to wire feeder.

4High speed position, screw holding feed plate to wire feeder.

To change the gear ratio:

1.Turn off power at the welding power source.

2.Open the wire drive door.

3.Use a 3/16" Allen wrench to remove the screws holding the feed plate to the wire feeder.

4.Use a Phillips screwdriver to remove the screw and washers holding the gear to the shaft.

5.Remove the gear.

6.Lightly cover the shaft with engine oil or equivalent. Install the desired gear onto the shaft.

7.Reassemble the screw and washers securing the gear to the shaft.

8.Reassemble the screws in the appropriate position for holding the feed plate to the wire feeder.

POWER FEED 10M SINGLE/DUAL