Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

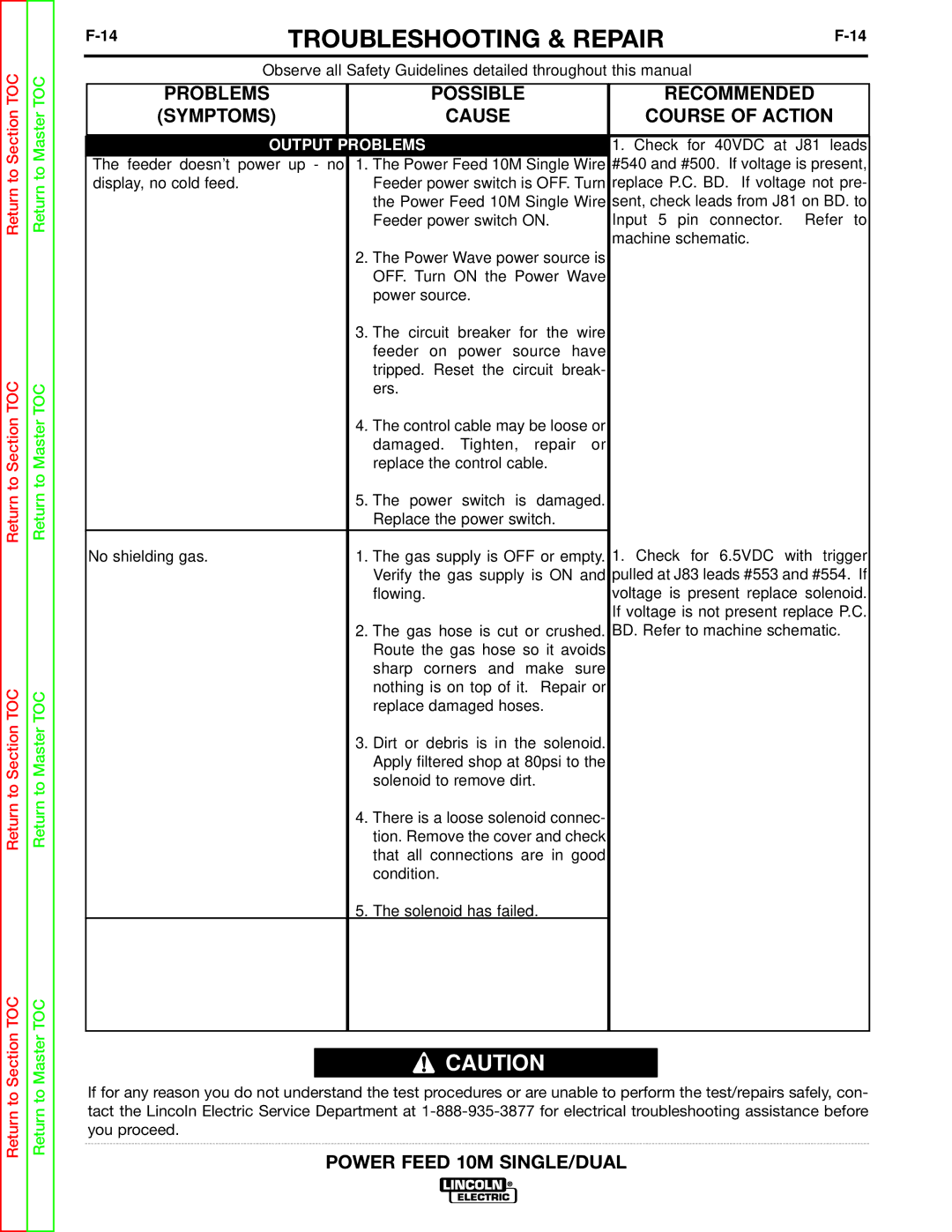

TROUBLESHOOTING & REPAIR | ||||||

|

|

|

|

| ||

| Observe all Safety Guidelines detailed throughout this manual |

| ||||

|

|

|

|

|

| |

| PROBLEMS |

|

| POSSIBLE | RECOMMENDED | |

| (SYMPTOMS) |

|

| CAUSE | COURSE OF ACTION | |

|

|

|

| |||

| OUTPUT | PROBLEMS | 1. Check for 40VDC at J81 leads | |||

| The feeder doesn’t power up - no | 1. The Power Feed 10M Single Wire | #540 and #500. If voltage is present, | |||

| display, no cold feed. |

|

| Feeder power switch is OFF. Turn | replace P.C. BD. If voltage not pre- | |

|

|

|

| the Power Feed 10M Single Wire | sent, check leads from J81 on BD. to | |

|

|

|

| Feeder power switch ON. | Input 5 pin connector. | Refer to |

|

|

|

|

| machine schematic. |

|

|

|

| 2. | The Power Wave power source is |

|

|

|

|

|

| OFF. Turn ON the Power Wave |

|

|

|

|

|

| power source. |

|

|

|

|

| 3. | The circuit breaker for the wire |

|

|

|

|

|

| feeder on power source have |

|

|

|

|

|

| tripped. Reset the circuit break- |

|

|

|

|

|

| ers. |

|

|

|

|

| 4. | The control cable may be loose or |

|

|

|

|

|

| damaged. Tighten, repair or |

|

|

|

|

|

| replace the control cable. |

|

|

|

|

| 5. | The power switch is damaged. |

|

|

|

|

|

| Replace the power switch. |

|

|

|

|

|

|

| 1. Check for 6.5VDC with trigger | |

| No shielding gas. |

| 1. | The gas supply is OFF or empty. | ||

|

|

|

| Verify the gas supply is ON and | pulled at J83 leads #553 and #554. If | |

|

|

|

| flowing. | voltage is present replace solenoid. | |

|

|

|

|

| If voltage is not present replace P.C. | |

|

|

| 2. | The gas hose is cut or crushed. | BD. Refer to machine schematic. | |

|

|

|

| Route the gas hose so it avoids |

|

|

|

|

|

| sharp corners and make sure |

|

|

|

|

|

| nothing is on top of it. Repair or |

|

|

|

|

|

| replace damaged hoses. |

|

|

|

|

| 3. | Dirt or debris is in the solenoid. |

|

|

|

|

|

| Apply filtered shop at 80psi to the |

|

|

|

|

|

| solenoid to remove dirt. |

|

|

|

|

| 4. | There is a loose solenoid connec- |

|

|

|

|

|

| tion. Remove the cover and check |

|

|

|

|

|

| that all connections are in good |

|

|

|

|

|

| condition. |

|

|

|

|

| 5. The solenoid has failed. |

|

| |

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department at