OPERATION | ||

|

|

|

Return to Master TOC

Return to Master TOC

LIMIT SETTING

The MSP4 can be optionally configured to limit the operator’s range of control of any weld parameter (weld WFS, arc con- trol, etc.). Limits are only available with the Dual Procedure/Memory Panel.

MACHINE SETUP/USER PREFERENCES

The MSP4 can be used to configure and troubleshoot the machine.

ACCESSING THE MACHINE SETUP MENU

To access the Machine Setup menu, press both MSP4 push buttons simultaneously. The MSP4

•Pressing the left MSP4 pushbutton will exit the entire Machine Setup menu while in the P.0 user preference.

•Turning the MSP4 encoder knob will select other available User Preferences.

•To exit the User Preference Menu, either rotate the MSP4 encoder until P.0 is displayed and press the left MSP4 pushbutton or press both MSP4 push buttons simultane- ously at any time.

SETUP FEATURES MENU

The Setup Menu gives access to the

•P.1 through P.99 Unsecured Parameters (always adjustable)

•P.101 through P.199 Diagnostic Parameters (always read only)

•P.501 through P.599 Secured Parameters (accessible only though a p.c. or palm application.)

To access the setup menu, press the right and left buttons of the MSP4 panel simultaneously. Note that the setup menu cannot be accessed if the system is welding, or if there is a fault (The status LED is not solid green).

Change the value of the blinking parameter rotating the SET knob.

To exit the setup menu at any time, press the right and left buttons of the MSP4 panel simultaneously. Alternately, 1 minute of inactivity will also exit the setup menu.

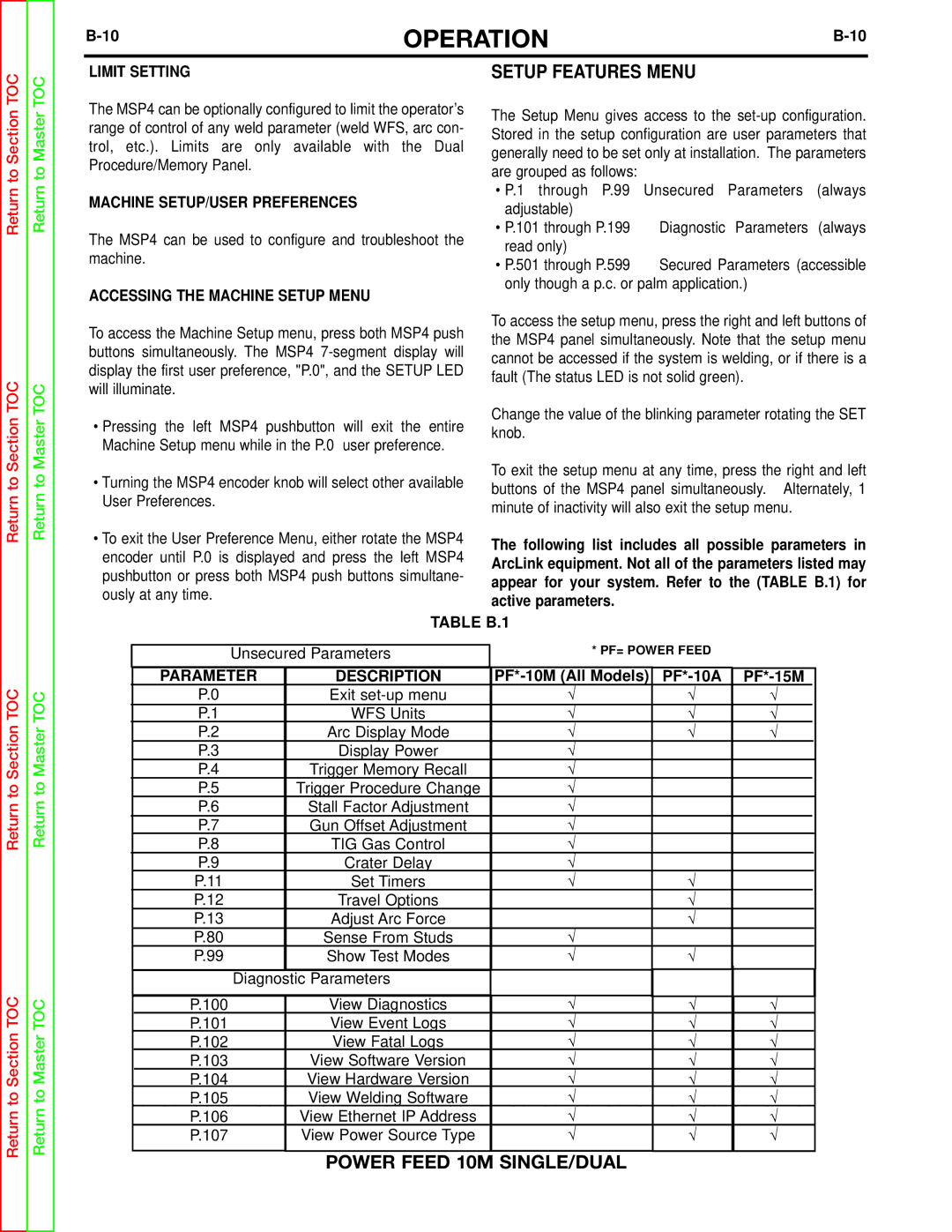

The following list includes all possible parameters in ArcLink equipment. Not all of the parameters listed may appear for your system. Refer to the (TABLE B.1) for active parameters.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

| TABLE B.1 |

|

|

| ||

|

| * PF= POWER FEED |

|

| ||

Unsecured Parameters |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| ||

PARAMETER | DESCRIPTION |

|

|

|

|

|

P.0 | Exit |

| √ | √ | √ | |

P.1 | WFS Units |

| √ | √ | √ |

|

P.2 | Arc Display Mode |

| √ | √ | √ | |

P.3 | Display Power |

| √ |

|

|

|

P.4 | Trigger Memory Recall |

| √ |

|

|

|

P.5 | Trigger Procedure Change |

| √ |

|

|

|

P.6 | Stall Factor Adjustment |

| √ |

|

|

|

P.7 | Gun Offset Adjustment |

| √ |

|

|

|

P.8 | TIG Gas Control |

| √ |

|

|

|

P.9 | Crater Delay |

| √ |

|

|

|

P.11 | Set Timers |

| √ | √ |

|

|

P.12 | Travel Options |

|

| √ |

|

|

P.13 | Adjust Arc Force |

|

| √ |

|

|

P.80 | Sense From Studs |

| √ |

|

|

|

P.99 | Show Test Modes |

| √ | √ |

|

|

|

|

|

|

|

|

|

Diagnostic Parameters |

|

|

|

|

| |

|

|

|

|

|

|

|

P.100 | View Diagnostics |

| √ | √ | √ | |

P.101 | View Event Logs |

| √ | √ | √ | |

P.102 | View Fatal Logs |

| √ | √ | √ | |

P.103 | View Software Version |

| √ | √ | √ | |

P.104 | View Hardware Version |

| √ | √ | √ | |

P.105 | View Welding Software |

| √ | √ | √ | |

P.106 | View Ethernet IP Address |

| √ | √ | √ | |

P.107 | View Power Source Type |

| √ | √ | √ | |

POWER FEED 10M SINGLE/DUAL