| INSTALLATION | |

|

|

|

Return to Master TOC

The Power Feed 10M Dual Wire Feeder is factory set for Electrode Positive welding.

Most welding procedures use Electrode Positive weld- ing. Some Innershield procedures may use Electrode Negative welding. For most applications, the Power Feed 10M Dual Wire Feeder will have both sides of the Wire Drive set to the same polarity. To weld with oppo- site polarities, each head would have to be welding on isolated work pieces and the weld cable attaching the two feed heads would have to be removed.

VOLTAGE SENSING

The best arc performance occurs when the PowerWaves have accurate data about the arc condi- tions. Depending upon the process, inductance within the electrode and work lead cables can influence the voltage apparent at the studs of the welder. Voltage sense leads improve the accuracy of the arc conditions and can have a dramatic effect on performance. Sense Lead Kits

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

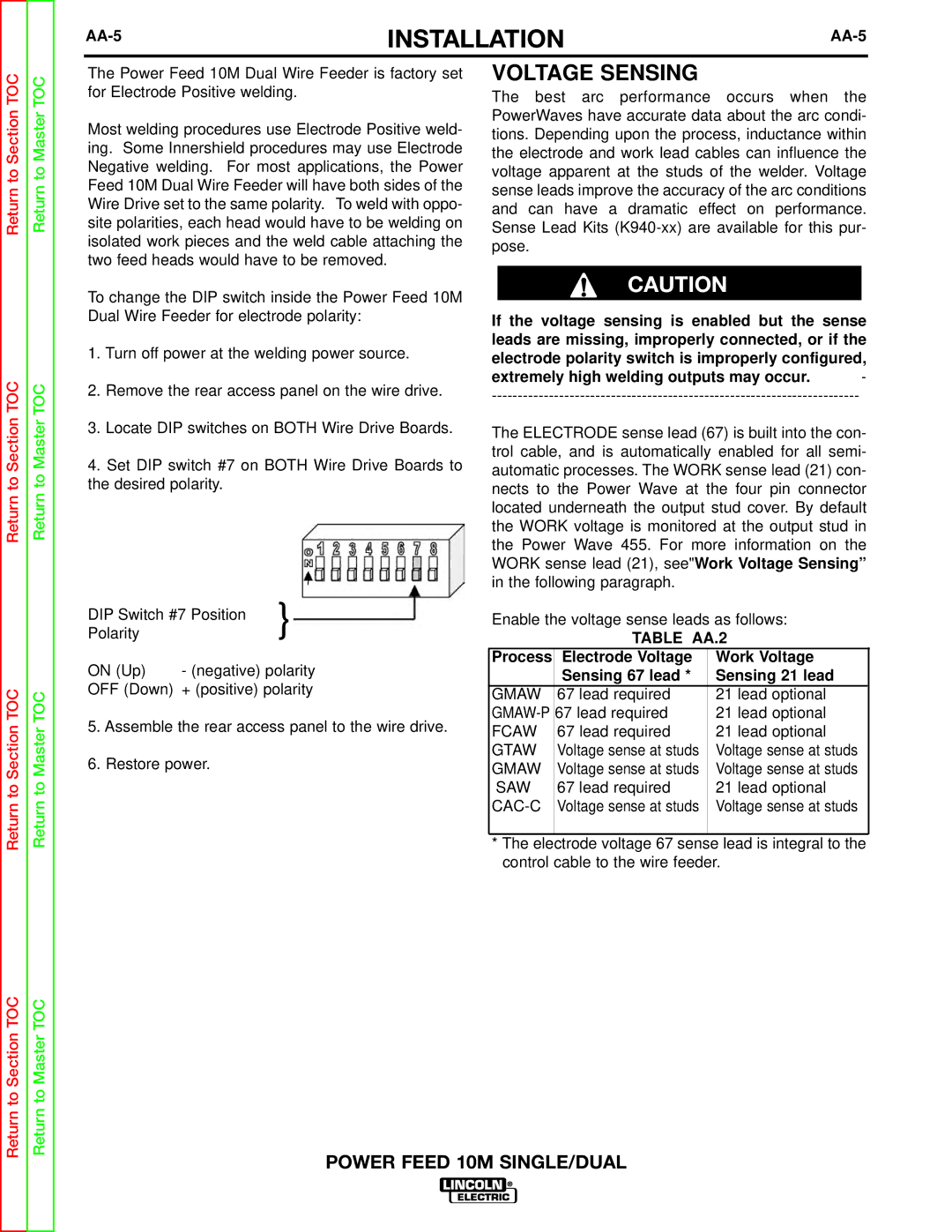

To change the DIP switch inside the Power Feed 10M Dual Wire Feeder for electrode polarity:

1.Turn off power at the welding power source.

2.Remove the rear access panel on the wire drive.

3.Locate DIP switches on BOTH Wire Drive Boards.

4.Set DIP switch #7 on BOTH Wire Drive Boards to the desired polarity.

DIP Switch #7 Position | } | |

Polarity |

| |

ON (Up) | - (negative) polarity | |

OFF (Down) | + (positive) polarity | |

5.Assemble the rear access panel to the wire drive.

6.Restore power.

CAUTION

If the voltage sensing is enabled but the sense leads are missing, improperly connected, or if the electrode polarity switch is improperly configured,

extremely high welding outputs may occur. | - |

|

The ELECTRODE sense lead (67) is built into the con- trol cable, and is automatically enabled for all semi- automatic processes. The WORK sense lead (21) con- nects to the Power Wave at the four pin connector located underneath the output stud cover. By default the WORK voltage is monitored at the output stud in the Power Wave 455. For more information on the WORK sense lead (21), see"Work Voltage Sensing” in the following paragraph.

Enable the voltage sense leads as follows:

TABLE AA.2

Process | Electrode Voltage | Work Voltage |

| Sensing 67 lead * | Sensing 21 lead |

GMAW | 67 lead required | 21 lead optional |

21 lead optional | ||

FCAW | 67 lead required | 21 lead optional |

GTAW | Voltage sense at studs | Voltage sense at studs |

GMAW | Voltage sense at studs | Voltage sense at studs |

SAW | 67 lead required | 21 lead optional |

| Voltage sense at studs | Voltage sense at studs |

*The electrode voltage 67 sense lead is integral to the control cable to the wire feeder.

Return to Section TOC

Return to Master TOC