| INSTALLATION | |

|

|

|

Return to Master TOC

OUTPUT CABLES, CONNECTIONS AND LIMITATIONS

Connect a work lead of sufficient size and length (Per Table AA.1) between the proper output terminal on the power source and the work. Be sure the connection to the work makes tight

For additional Safety information regarding the elec- trode and work cable

CAUTION

Excessive voltage drops caused by poor work piece connections often result in unsatisfactory welding performance.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

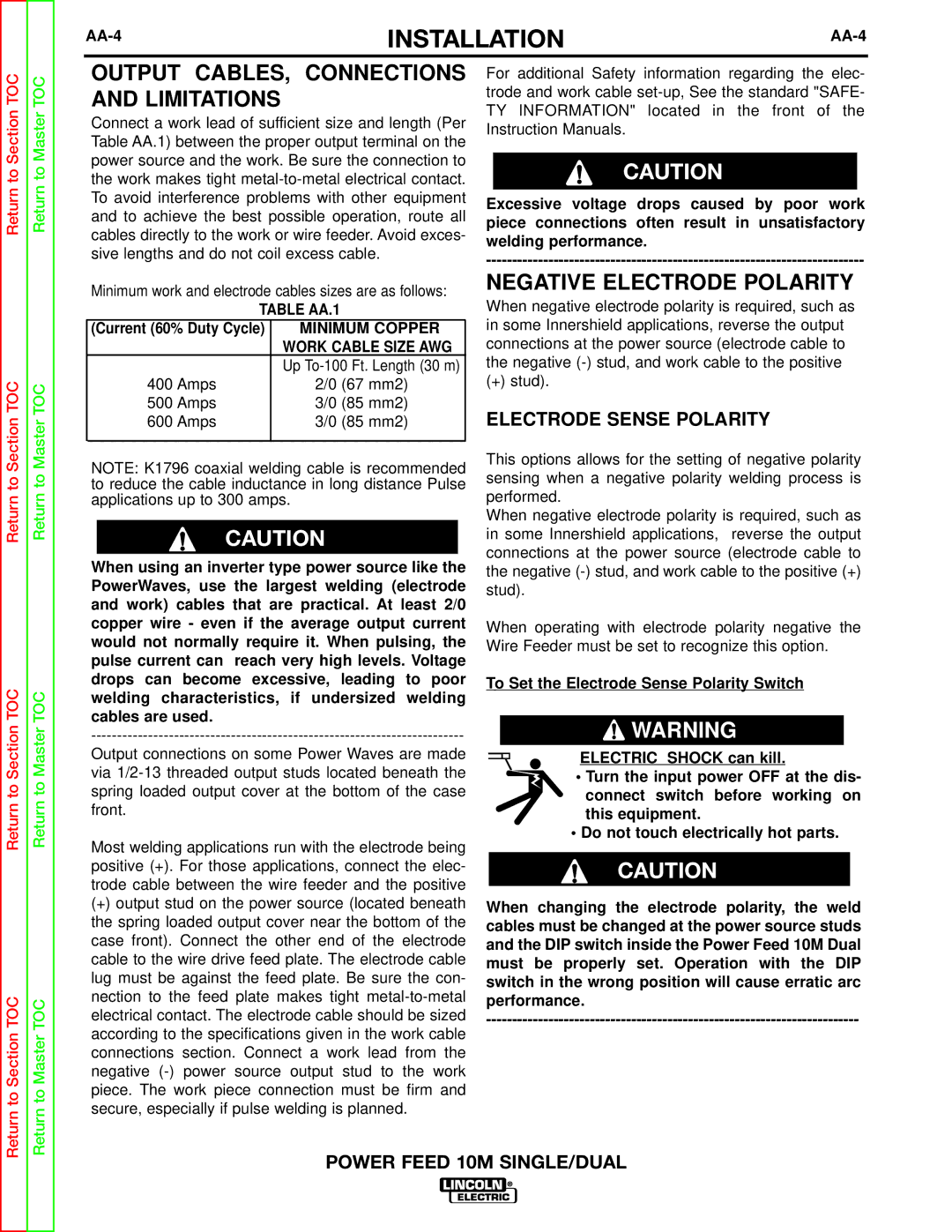

Minimum work and electrode cables sizes are as follows:

TABLE AA.1

(Current (60% Duty Cycle) MINIMUM COPPER WORK CABLE SIZE AWG

| Up |

400 Amps | 2/0 (67 mm2) |

500 Amps | 3/0 (85 mm2) |

600 Amps | 3/0 (85 mm2) |

NOTE: K1796 coaxial welding cable is recommended to reduce the cable inductance in long distance Pulse applications up to 300 amps.

CAUTION

When using an inverter type power source like the PowerWaves, use the largest welding (electrode and work) cables that are practical. At least 2/0 copper wire - even if the average output current would not normally require it. When pulsing, the pulse current can reach very high levels. Voltage drops can become excessive, leading to poor welding characteristics, if undersized welding cables are used.

Output connections on some Power Waves are made via

Most welding applications run with the electrode being positive (+). For those applications, connect the elec- trode cable between the wire feeder and the positive

(+)output stud on the power source (located beneath the spring loaded output cover near the bottom of the case front). Connect the other end of the electrode cable to the wire drive feed plate. The electrode cable lug must be against the feed plate. Be sure the con- nection to the feed plate makes tight

NEGATIVE ELECTRODE POLARITY

When negative electrode polarity is required, such as in some Innershield applications, reverse the output connections at the power source (electrode cable to the negative

(+) stud).

ELECTRODE SENSE POLARITY

This options allows for the setting of negative polarity sensing when a negative polarity welding process is performed.

When negative electrode polarity is required, such as in some Innershield applications, reverse the output connections at the power source (electrode cable to the negative

When operating with electrode polarity negative the Wire Feeder must be set to recognize this option.

To Set the Electrode Sense Polarity Switch

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

•Turn the input power OFF at the dis- connect switch before working on this equipment.

•Do not touch electrically hot parts.

CAUTION

When changing the electrode polarity, the weld cables must be changed at the power source studs and the DIP switch inside the Power Feed 10M Dual must be properly set. Operation with the DIP switch in the wrong position will cause erratic arc performance.