Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OPERATION | ||

|

|

|

MACHINE FUNCTIONALITY BY WELD PROCESS

CV GMAW/FCAW (NON-SYNERGIC)

Use the following tables to review how the machine functions (output controls, arc control, Start options and weld options) for the weld modes listed in the top table.

CV NON-SYNERGIC MODES

Material | PROCESS | WELD MODE |

|

|

|

Steel | GMAW, CV | 5 |

|

|

|

Steel | GMAW, POWER MODE | 40 |

Steel | FCAW, CV | 6 |

|

|

|

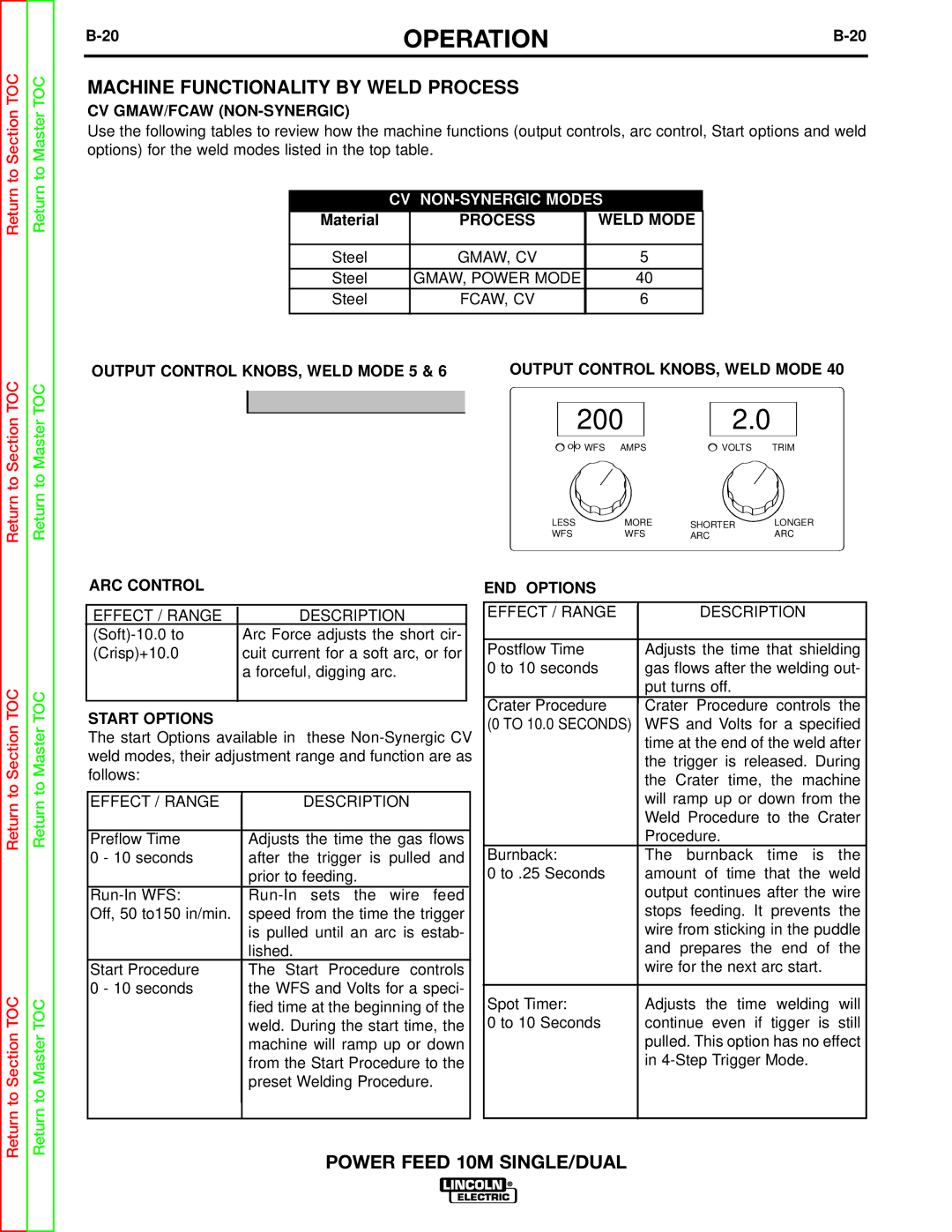

OUTPUT CONTROL KNOBS, WELD MODE 5 & 6 OUTPUT CONTROL KNOBS, WELD MODE 40

300 | 25.3 | 200 | 2.0 |

WFS AMPS | VOLTS TRIM | WFS AMPS | VOLTS TRIM |

|

|

LESS | MORE | LESS | MORE | LESS | MORE | SHORTER | LONGER | |

WFS | WFS | WFS | WFS | ARC | ARC | |||

VOLTS | VOLTS | |||||||

|

|

|

|

|

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

ARC CONTROL

|

|

|

|

|

|

| EFFECT / RANGE |

|

| DESCRIPTION |

|

|

|

| Arc Force adjusts the short cir- |

| |

| (Crisp)+10.0 |

|

| cuit current for a soft arc, or for |

|

|

|

|

| a forceful, digging arc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

START OPTIONS

The start Options available in these

|

|

|

|

|

EFFECT / RANGE |

|

| DESCRIPTION |

|

|

|

|

|

|

Preflow Time |

|

| Adjusts the time the gas flows |

|

0 - 10 seconds |

|

| after the trigger is pulled and |

|

|

|

| prior to feeding. |

|

|

|

| ||

Off, 50 to150 in/min. |

|

| speed from the time the trigger |

|

|

|

| is pulled until an arc is estab- |

|

|

|

| lished. |

|

Start Procedure |

|

| The Start Procedure controls |

|

0 - 10 seconds |

|

| the WFS and Volts for a speci- |

|

|

|

| fied time at the beginning of the |

|

|

|

| weld. During the start time, the |

|

|

|

| machine will ramp up or down |

|

|

|

| from the Start Procedure to the |

|

|

|

| preset Welding Procedure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

END OPTIONS

|

|

|

|

|

EFFECT / RANGE |

|

| DESCRIPTION |

|

|

|

|

|

|

Postflow Time |

|

| Adjusts the time that shielding |

|

0 to 10 seconds |

|

| gas flows after the welding out- |

|

|

|

| put turns off. |

|

Crater Procedure |

|

| Crater Procedure controls the |

|

|

|

| ||

(0 TO 10.0 SECONDS) |

|

| WFS and Volts for a specified |

|

|

|

| time at the end of the weld after |

|

|

|

| the trigger is released. During |

|

|

|

| the Crater time, the machine |

|

|

|

| will ramp up or down from the |

|

|

|

| Weld Procedure to the Crater |

|

|

|

| Procedure. |

|

Burnback: |

|

| The burnback time is the |

|

0 to .25 Seconds |

|

| amount of time that the weld |

|

|

|

| output continues after the wire |

|

|

|

| stops feeding. It prevents the |

|

|

|

| wire from sticking in the puddle |

|

|

|

| and prepares the end of the |

|

|

|

| wire for the next arc start. |

|

|

|

|

|

|

Spot Timer: |

|

| Adjusts the time welding will |

|

0 to 10 Seconds |

|

| continue even if tigger is still |

|

|

|

| pulled. This option has no effect |

|

|

|

| in |

|

|

|

|

|

|

|

|

|

|

|

POWER FEED 10M SINGLE/DUAL