OPERATION | ||

|

|

|

Return to Master TOC

Return to Master TOC

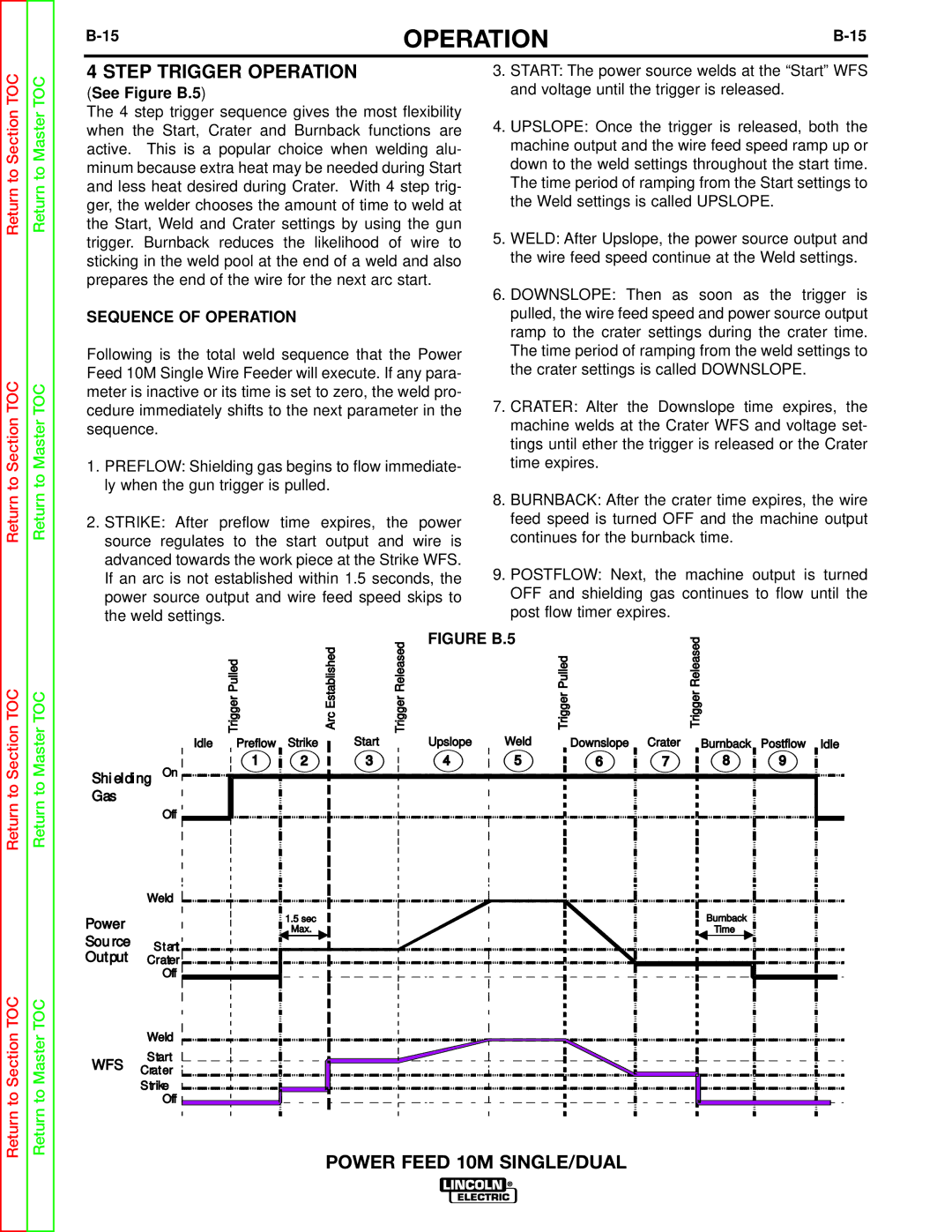

4 STEP TRIGGER OPERATION

(See Figure B.5)

The 4 step trigger sequence gives the most flexibility when the Start, Crater and Burnback functions are active. This is a popular choice when welding alu- minum because extra heat may be needed during Start and less heat desired during Crater. With 4 step trig- ger, the welder chooses the amount of time to weld at the Start, Weld and Crater settings by using the gun trigger. Burnback reduces the likelihood of wire to sticking in the weld pool at the end of a weld and also prepares the end of the wire for the next arc start.

SEQUENCE OF OPERATION

Following is the total weld sequence that the Power Feed 10M Single Wire Feeder will execute. If any para- meter is inactive or its time is set to zero, the weld pro- cedure immediately shifts to the next parameter in the sequence.

1.PREFLOW: Shielding gas begins to flow immediate- ly when the gun trigger is pulled.

2.STRIKE: After preflow time expires, the power source regulates to the start output and wire is advanced towards the work piece at the Strike WFS. If an arc is not established within 1.5 seconds, the power source output and wire feed speed skips to the weld settings.

3.START: The power source welds at the “Start” WFS and voltage until the trigger is released.

4.UPSLOPE: Once the trigger is released, both the machine output and the wire feed speed ramp up or down to the weld settings throughout the start time. The time period of ramping from the Start settings to the Weld settings is called UPSLOPE.

5.WELD: After Upslope, the power source output and the wire feed speed continue at the Weld settings.

6.DOWNSLOPE: Then as soon as the trigger is pulled, the wire feed speed and power source output ramp to the crater settings during the crater time. The time period of ramping from the weld settings to the crater settings is called DOWNSLOPE.

7.CRATER: Alter the Downslope time expires, the machine welds at the Crater WFS and voltage set- tings until ether the trigger is released or the Crater time expires.

8.BURNBACK: After the crater time expires, the wire feed speed is turned OFF and the machine output continues for the burnback time.

9.POSTFLOW: Next, the machine output is turned OFF and shielding gas continues to flow until the post flow timer expires.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

| Trigger Pulled |

Idle | Preflow |

1

Shi elding On

Gas

Gas

Off ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Arc Established | Trigger Released |

Strike Start

2 3

FIGURE B.5

Trigger Pulled

Upslope Weld Downslope

4 ![]() 5

5 ![]() 6

6

Trigger Released

Crater | Burnback | Postflow | Idle |

7 | 8 | 9 |

|

Return to Section TOC

Return to Master TOC

Power | Weld |

|

|

|

| |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1.5 sec | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Max. | ||

Source | Start |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Output | Crater |

|

| |||||||||||||||||

| ||||||||||||||||||||

| Off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Weld

Start

WFS Crater

Strike

Off ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Burnback |

Time |

POWER FEED 10M SINGLE/DUAL