OPERATION | ||

|

|

|

Return to Master TOC

PROCESS SETUP AND OPERATION

The Power Feed/Power Wave system delivers world class arc performance for a wide variety of processes. Using the foundation of Waveform Control Technology™, each weld mode is precisely tuned to meet exacting standards for low spatter, weld bead profile and arc shape.

Customized welding software means even the most difficult materials can by welded with the Power Feed/Power Wave system. Copper, Nickel, Silicon Bronze are just a few of the unusual alloys the Power Feed system welds with ease when special software is loaded.

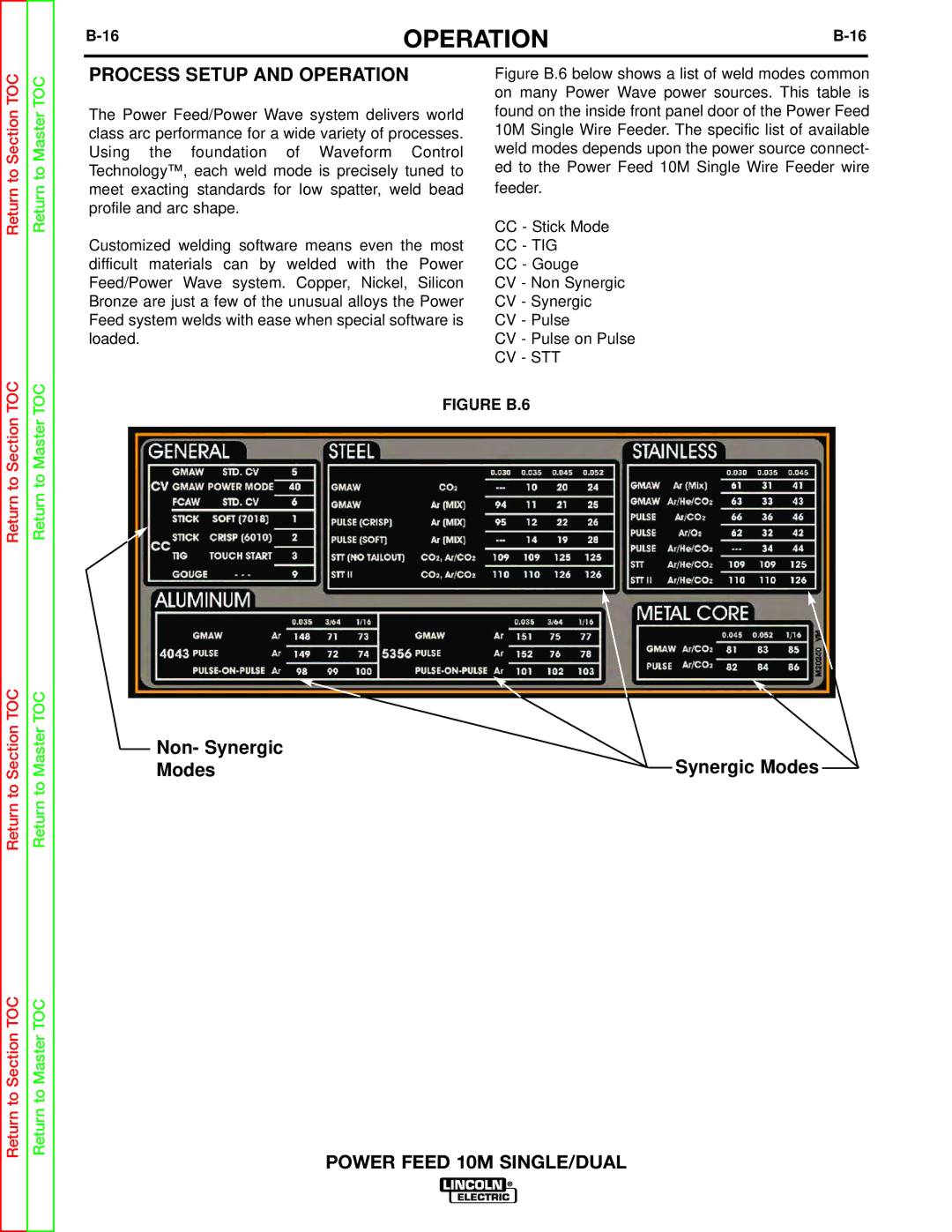

Figure B.6 below shows a list of weld modes common on many Power Wave power sources. This table is found on the inside front panel door of the Power Feed 10M Single Wire Feeder. The specific list of available weld modes depends upon the power source connect- ed to the Power Feed 10M Single Wire Feeder wire feeder.

CC- Stick Mode

CC - TIG CC - Gouge

CV - Non Synergic CV - Synergic CV - Pulse

CV - Pulse on Pulse

CV - STT

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

FIGURE B.6

Non- Synergic | Synergic Modes |

Modes |

POWER FEED 10M SINGLE/DUAL