Appendix J: PROFIBUS PA Profile Structure

PROFIBUS Level Device Design

The device follows the profile block model and is implemented as a Profile 3.01, Class B, PA device. Standard profile parameters are used to program the Level Transducer Block.

Block Model for recording and processing measured values

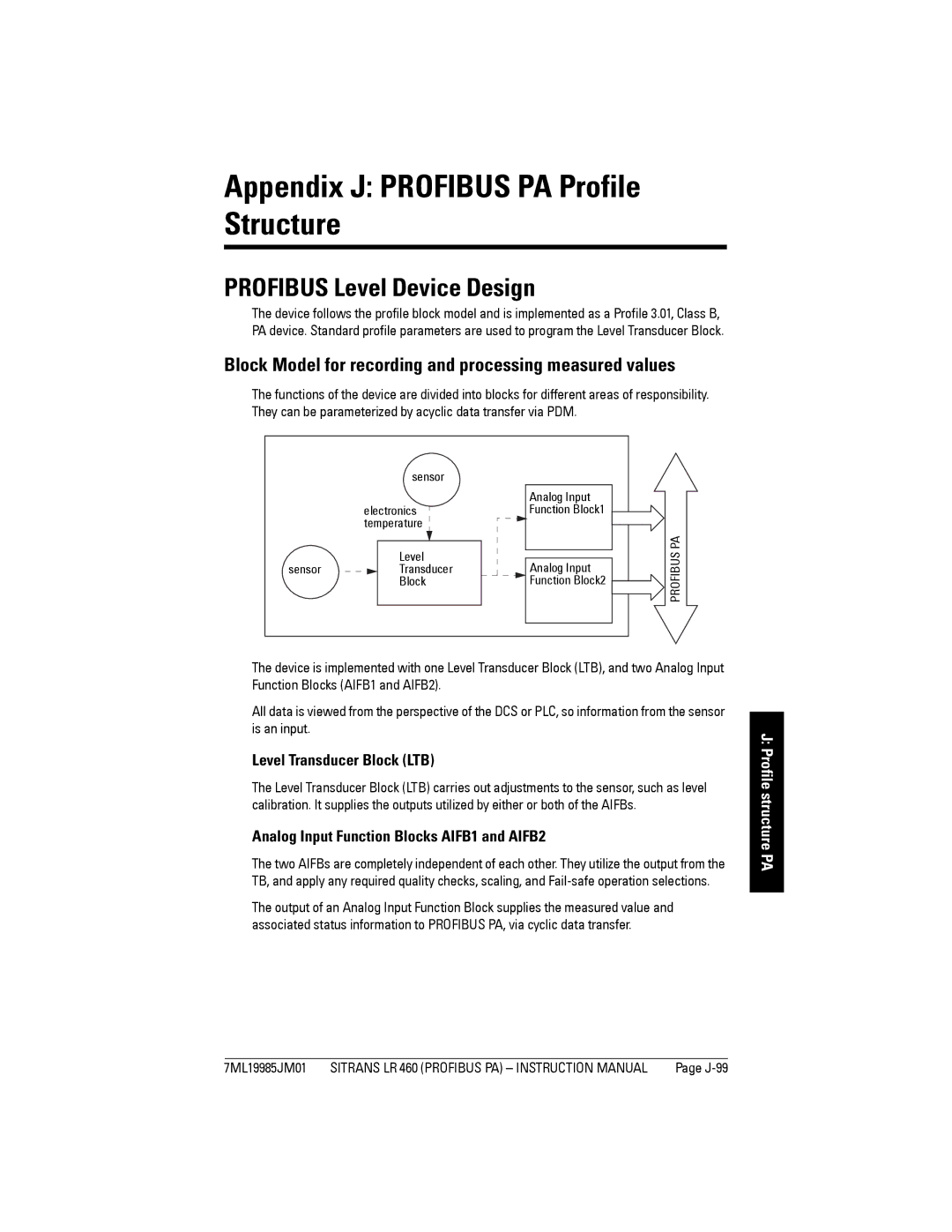

The functions of the device are divided into blocks for different areas of responsibility. They can be parameterized by acyclic data transfer via PDM.

| sensor |

| electronics |

| temperature |

| Level |

sensor | Transducer |

| Block |

Analog Input |

|

Function Block1 |

|

| PA |

Analog Input | PROFIBUS |

Function Block2 |

|

The device is implemented with one Level Transducer Block (LTB), and two Analog Input Function Blocks (AIFB1 and AIFB2).

All data is viewed from the perspective of the DCS or PLC, so information from the sensor is an input.

Level Transducer Block (LTB)

The Level Transducer Block (LTB) carries out adjustments to the sensor, such as level calibration. It supplies the outputs utilized by either or both of the AIFBs.

Analog Input Function Blocks AIFB1 and AIFB2

The two AIFBs are completely independent of each other. They utilize the output from the TB, and apply any required quality checks, scaling, and

The output of an Analog Input Function Block supplies the measured value and associated status information to PROFIBUS PA, via cyclic data transfer.

J: Profile structure PA

7ML19985JM01 | SITRANS LR 460 (PROFIBUS PA) – INSTRUCTION MANUAL | Page |