Air Purging System (Optional)

For more frequent cleaning, a purging system can be installed between the flange and the horn antenna. The system provides an 1/8" inlet (female thread) on the flange where cooling air or cleaning fluid passes through the flange and exits the inside of the horn to clean it. The customer will supply the purging medium by a manual or automatic valve system.

This option is only available with the universal flange for purging shown on page 17.

Notes:

•The Air Purge feature should not be activated with a dust cap in place.

•Purge duration, pressure, and interval, will vary with each application. It is the user’s responsibility to determine the requirements depending on the application and cleaning required.

•Short duration bursts of high pressure provide more effective cleaning than continuous low pressure air.

•Some dust particles are highly abrasive and can be drawn into the inside of the horn during purge cleaning, damaging the internal PTFE emitter of the antenna. A replacement kit is available from your local Siemens Milltronics representative.

•It is the customer’s responsibility to ensure that any vacuum or pressure in the measured vessel is maintained, considering the hole that passes through the process connection and SITRANS LR 460 antenna system.

Recommendation for |

| Air Consumption | |

effective cleaning | (Flow rate versus applied pressure) | ||

| Air Pressure |

| Approx. inlet volume flow rate |

Pressure: 90 to 110 psi | 20 |

| 5 SCFM |

| 40 |

| 6 SCFM |

Inlet flow: 10 SCFM 1 | 60 |

| 8 SCFM |

80 |

| 9 SCFM | |

| 90 |

| 10 SCFM |

Installation

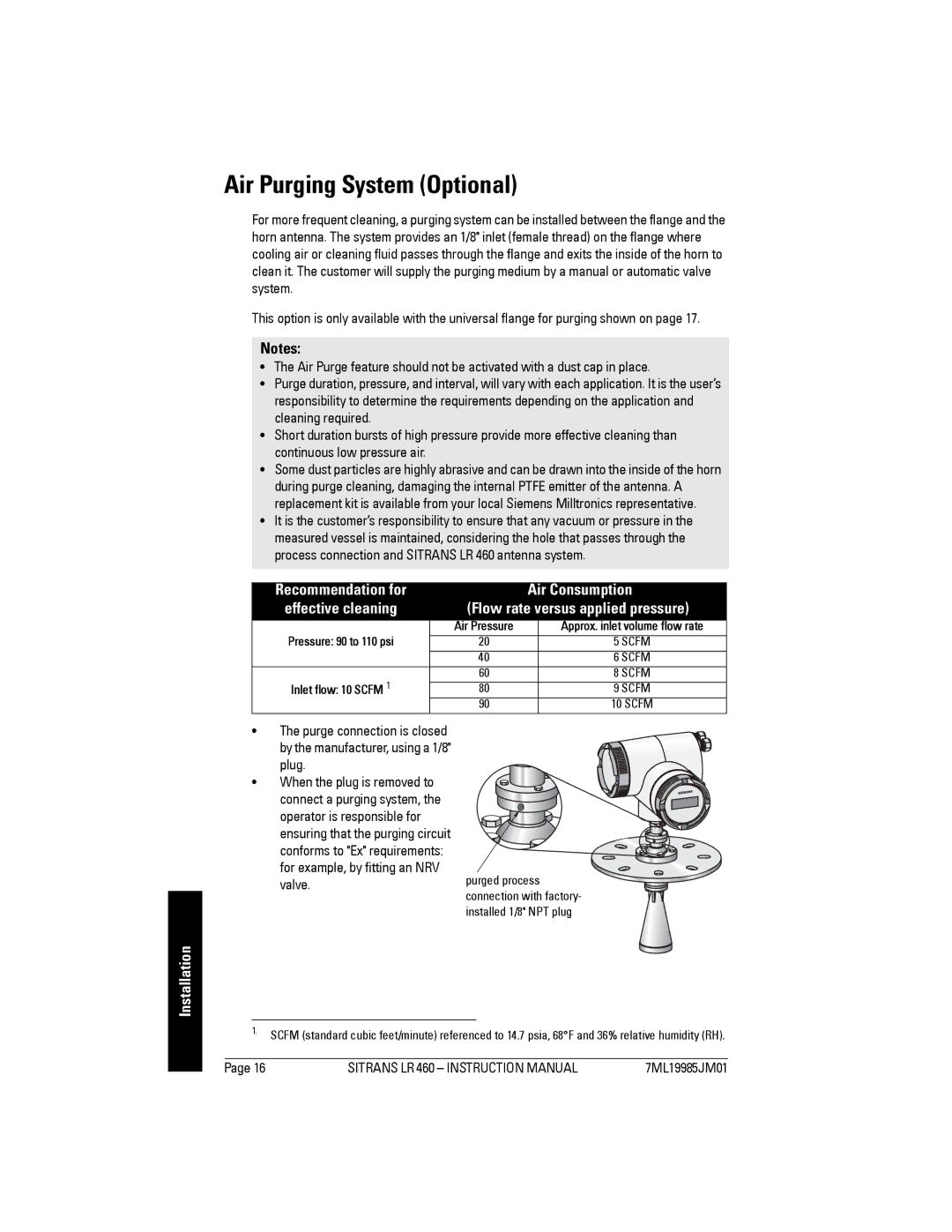

•The purge connection is closed by the manufacturer, using a 1/8" plug.

•When the plug is removed to connect a purging system, the operator is responsible for ensuring that the purging circuit conforms to "Ex" requirements: for example, by fitting an NRV valve.

purged process connection with factory- installed 1/8" NPT plug

1.SCFM (standard cubic feet/minute) referenced to 14.7 psia, 68°F and 36% relative humidity (RH).

Page 16 | SITRANS LR 460 – INSTRUCTION MANUAL | 7ML19985JM01 |