Controls, Start-Up, Operation, Service and Troubleshooting

Contents

Contents

Safety Considerations

Series Product Line

General

Basic Control Usage

Sents pressing Enter to move into the next level

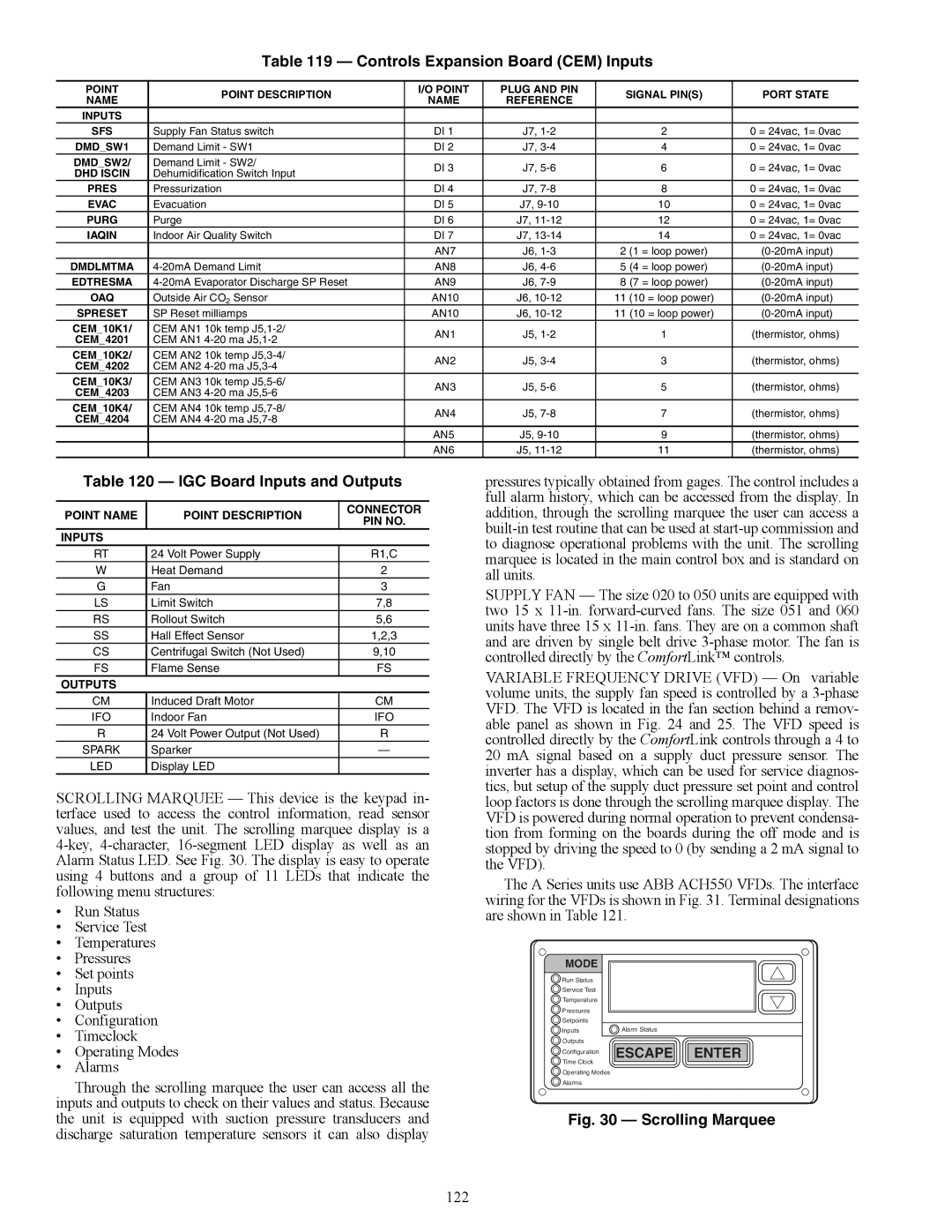

Scrolling Marquee

System Pilot User Interface

Test

START-UP

Fan Performance 48AJ,AK020,025 and 48A2,A3020 Units

Fan Performance 48AJ,AK027,030 and 48A2,A3025-030 Units

Fan Performance 48AJ,AK,A2,A3035 Units

Fan Performance 48AJ,AK036 Units

Fan Performance 48AJ,AK,A2,A3040 Units

Fan Performance 48AJ,AK041 Units

Fan Performance 48AJ,AK,A2,A3050 Units

Fan Performance 48AJ,AK051 Units

Fan Performance 48AJ,AK,A2,A3060 Units

Fan Performance 50AJ,AK020,025 and 50A2,A3020 Units

Fan Performance 50AJ,AK027,030 and 50A2,A3025-030 Units

Fan Performance 50AJ,AKA2,A3035 Units

Fan Performance 50AJ,AK036 Units

Fan Performance 50AJ,AK,A2,A3040 Units

Fan Performance 50AJ,AK041 Units

Fan Performance 50AJ,AK,A2,A3050 Units

Fan Performance 50AJ,AK051 Units

Fan Performance 50AJ,AK,A2,A3060 Units

Fan Performance 48AW,AY020,025 and 48A4,A5020 Units

Fan Performance 48AW,AY027,030 and 48A4,A5025-030 Units

Fan Performance 48AW,AY,A4,A5035 Units

Fan Performance 48AW,AY036 Units

Fan Performance 48AW,AY,A4,A5040 Units

Fan Performance 48AW,AY041 Units

Fan Performance 48AW,AY,A4,A5050 Units

Fan Performance 48AW,AY051 Units

Fan Performance 48AW,AY,A4,A5060 Units

Fan Performance 50AW,AY020,025 and 50A4,A5020 Units

Fan Performance 50AW,AY027,030 and 50A4,A5025-030 Units

Fan Performance 50AW,AY,A4,A5035 Units

Fan Performance 50AW,AY036 Units

Fan Performance 50AW,AY,A4,A5040 Units

Fan Performance 50AW,AY041 Units

Fan Performance 50AW,AY,A4,A5050 Units

Fan Performance 50AW,AY051 Units

Fan Performance 50AW,AY,A4,A5060 Units

Motor Limitations

Air Quantity Limits 48AJ,AK,AW,AY,A2,A3,A4,A5

Controls Quick Start

Air Quantity Limits 50AJ,AK,AW,AY,A2,A3,A4,A5

Page

Service Test

Indoor Air Quality IAQ Options

Service Test

MLV

Third Party Control

Demand Controlled Ventilation Control

Controls Operation

Operating Modes Display Table

Expansion Range CCN Point

Hvac

TYP = 3 TSTAT-MULTI

TYP = 6 SPT-2 STG

There will be no MAT calculation

Unit Configuration

Expansion Range Units CCN Point Defaults

Under Configuration→UNIT

Setpoints

Machine Dependent Configurations

Supply Air Reset Configuration

Cooling Configuration

Advanced Scroll Temperature Protection Label

Are VAV occupied cooling offsets under Setpoints

Cool Mode Evaluation

Cool/Heat Set Point Offsets Configuration

LV.T

Stage Sequence

Stage Sequence 48/50AJ,AW020-027

Stage Sequence 48/50AJ,AW030-060

Stage Sequence 48/50A2,A4030-060

Staging Sequence with Hot Gas Bypass 48/50AK,AY030-060

Stage Sequence 48/50A2,A4020-027

Staging Sequence with Hot Gas Bypass 48/50A3,A5030-060

Run Status Mode Trip Helper

PCT = MAT EDT/ C.CAP

Run Status Cool Display

Expansion Range Units CCN Point Write Status

Control will not attempt to learn MAT over time

Inputs→GEN.I→DL.S1 Inputs→GEN.I→DL.S2

Demand Limit Configuration

Expansion Range Units CCN Point Default

Condenser Fan Staging

FAN Relay 48/50A Unit Size

Heating Configuration

Occupied Heating Enable OC.EN This configuration

Expansion Range Units CCN Default Point Ohsp

Uhsp

Mode Trip Helper Table

Expansion Units CCN Point

Unit Size

Staged Gas Configuration

Staged Gas Heat 48AJ,AK,AW,AY Units

Unit Model no

Staged Gas Heat 48A2,A3,A4,A5 Units

Relay Output Stage

LED Indication Error Code

IGC LED Indicators

Hvac mode = Tempering Vent

Capacity

Page

As an example, the static pressure reset limit SP.LM =

Static Pressure Control Configuration

Fan Status Monitoring

Dirty Filter Switch Points

Static Pressure Reset Related Points

Fan Status Monitoring Configuration

None

Outdoor Enthalpy Changeover

Economizer Configuration Table

Custom Changeover Curve Example

SPT 2 Stage

Tstat 2 Stage

SPT Multi-Staging

Economizer Run Status Table

PE.A PE.B PE.C

Building Pressure Configuration

Power Exhaust Staging BP.CF =

PID

Expansion Range CCN Write Point Status

Indoor Air Quality Control The indoor air quality

Trol can also be set up to respond to a discrete IAQ input

Described above when DAQ is above the DAQ Fan On Set

Will be turned off when DAQ is below the DAQ Fan Off Set

IQ.A.F = 2 Fan On Occupied/Unoccupied IAQ

IAQ Purge Configuration → IAQ → IAQ.P → IQ.PG

Indoor Air Quality Configuration

Dehumidification Configuration

Expansion Range Units CCN Point

Temperature Compensated Start This logic is

Carrier Comfort Network CCN System It

CCN Configuration

Expansion Range Units Point Default

Alert Limit Configuration

Sensor Trim Configuration

Discrete Switch Logic Configuration The SW.LG

Display Configuration

Time Clock Configuration

Switch Logic Configuration

Remote Switch Configuration

Closed

Remote Switch Logic Configuration

Open

Troubleshooting

Time Clock Configuration

Compressor Stops on High Pressure

Cooling Service Analysis

Problem Solution Compressor does not RUN

Compressor Cycles on LOW Pressure

Compressor Loses OIL

Unit Operates TOO Long or Continuously

System is Noisy

Frosted Suction Line

Problem Cause Remedy

Gas Heating Service Analysis

Electric Heat Service Analysis

IGC Service Analysis Logic

5K Thermistor Temperature vs. Resistance SCT Sensors English

5K Thermistor Temperature vs. Resistance SCT Sensors SI

143

Pressure Voltage Psig Drop

Pressure Voltage Psig

Pressure Voltage Psig Drop

175

503

PCT = MAT EDT/C.CAP

Expansion Range Units Point Write Status

Auto View of Run Status Display Table

Economizer Run Status Display Table

CCN/Linkage Display Table

Mode Trip Helper Display Table

Cooling Information Display Table

Compressor Run Hours Display Table

Expansion Range Units Point Write Status Tmgd

Time Guard Display Table

Software Version Numbers Display Table

Expansion Range Units Point Write Status Vers

Alert and Alarm Codes

P051

CEM

Check for welded contactor Verify CS wiring

T122 Circuit a High Saturated Suction Temperature

Page

Page

At Configuration→UNIT→SENS→FLT.S

Factory-Installed Components

Major System Components

102

103

104

Typical Auxiliary Control Box Wiring Schematic

105

~~~ ~~~~

106

107

108

109

110

111

112

Typical Power Schematic 48/50A2,A3,A4,A5060 Unit Shown

113

Typical Controls Option Wiring Schematic

114

115

Typical Small Chassis Component Location Size 020-035 Units

116

Typical Large Chassis Component Locations Size 036-060 Units

117

Main Control Board MBB Inputs and Outputs

118

Economizer Control Board ECB1 Inputs and Outputs

119

Outputs Sfanvfd

VAV Control Board ECB2 Inputs and Outputs

120

Staged Gas Control Board SCB Inputs and Outputs

121

122

Controls Expansion Board CEM Inputs

IGC Board Inputs and Outputs

123

Terminal Function

Board SW1 SW2 SW3 SW4 ECB1 ECB2 SCB CEM

W2 G

124

Field Connection Terminal Strips

125

126

IME

Hvac

127

CID

Service

128

Gas Heat Section Details

Lubrication

Manufacturer Lubricant

Evaporator-Fan Motor Replacement

Evaporator Fan Service and Replacement

Belt Tension Adjustment To adjust belt tension

131

132

Condenser-Fan Adjustment

Round Tube, Plate Fin Unit Charge

Unit Refrigerant Size Liquid

Charging Chart 48/50A2,A3,A4,A5020 with R-410A Refrigerant

133

27 Ton Mchx Circuit a Charging Chart

134

Charging Chart 48/50A2,A3,A4,A5030 with R-410A Refrigerant

135

Charging Chart 48/50A2,A3,A4,A5035 with R-410A Refrigerant

136

Charging Chart 48/50A2,A3,A4,A5040 with R-410A Refrigerant

Charging Chart 48/50A2,A3,A4,A5050 with R-410A Refrigerant

Charging Chart 48/50A2,A3,A4,A5060 with R-410A Refrigerant

138

Gas Valve Part Number EF33CW271

Main Burner Removal

Mode RUN Status

140

Appendix a Local Display Tables

141

Description Range Units CCN Point Default

142

Mode Inputs

143

Mode Configuration

144

145

→BP.SP

146

→SC.OV→SPT.O

Mode Time Clock

147

Appendix B CCN Tables

148

149

Appendix B CCN Tables

Status Display Tables

Tstat

150

Display Name Range Units Point Name Write Status Temps

Uinputs

151

Name Range Units Point Name Default Allm

Config Tables

Name Range Units Point Name Default Schedovr

152

SERVICE-CONFIG Tables

153

Trim

Name Range Units Point Name Default Heat

154

Name Range Units Point Name Default Swlg

155

156

Display Name Range Units Point Name Write Status ALARMS01

ALARMS02 ALARMS03 ALARMS04 ALARMS05 Compresr

Dmandlim

Display Name Range Units Point Name Write Status Econmin

Maintenance Display Tables

157

Ecdiag

158

159

160

161

Appendix C VFD Information

Table a VFD Terminal Designations

Over Ride

Table B VFD Configurations

Appendix C VFD Information

Fig. C Standard Display Example

Appendix C VFD Information

Appendix C VFD Information

Table C Fault Codes

166

Table E Maintenance Intervals

Table D Alarm Codes

Replace the cooling fan Restore power

167

Fig. D Main Fan Replacement Frame Sizes R1-R4

Fig. F Internal Enclosure Fan Replacement

169

Appendix D Mode Selection Process

Appendix E UPC Open Controller

171

172

Table a SW3 Protocol Switch Settings For MS/TP

Table B Baud Selection Table

DS8 DS7 DS6 DS5 DS4 DS3

173

Table C MS/TP Wiring Recommendations

Appendix E UPC Open Controller

Rmcorp

Wiring Specifications Recommended Vendors and Part Numbers

174

CMP

175

Table E LED Status Indicators

RUN LED Error LED Status

LED Status

176

Bacnet Point Name Read Units Default Range Object ID

Network Points List

Object Name Point

Appendix E UPC Open Controller Network Points List

177

178

Bacnet Point Name Read Units Default Range Object ID Only

179

180

181

182

Index

183

Copyright 2010 Carrier Corporation

Controls SET Point and Configuration LOG

Expansion Range Default Entry

CL-2

CL-3

CL-4

CL-5

Unit START-UP Checklist

PRE-START-UP