Compensated Start section for more information. A setting of 0 minutes indicates Temperature Compensated Start in Cooling is not permitted.

Temperature Compensated Start Heating Factor (TCS.H) — This factor is used in the equation of the Temperature Compen- sated Start Time Bias for heating. Refer to the Temperature Compensated Start section for more information. A setting of 0 minutes indicates Temperature Compensated Start in Heating is not permitted.

Fan Fail Shuts Downs Unit (SFS.S) — This configuration will determine whether the unit should shut down on a supply fan status fail or simply alert the condition and continue to run. If set to YES, then the control will shut down the unit and send out an alarm if supply fan status monitoring fails. If set to NO, the control will not shut down the unit if supply fan status mon- itoring fails but the control will send out an alert.

Fan Status Monitoring (SFS.M) — This configuration selects the type of fan status monitoring to be performed.

0 - NONE — No switch or monitoring

1 - SWITCH — Use of the fan status switch

2 - SP RISE — Monitoring of the supply duct pressure.

VAV Unoccupied Fan Retry Time (VAV.S) — Machine con- trol types 1 and 2

Unit Size (SIZE) — There are several unit sizes (tons) for the A Series control. Make sure this configuration matches the size called out by the model number of the unit. This is important as the cooling stage tables are directly determined based on this configuration.

Discharge Pressure Transducers (DP.XR) — This configuration configures the unit for use with discharge pressure transducers. The 48/50A2,A3,A4,A5 units will be automatically configured for discharge pressure transducers and DP.XR should be set to Yes.

Suction Pressure Transducer Type (SP.XR) — This configu- ration specifies the type of suction pressure transducer that is being used. Set SP.XR to 0 for support of a pressure transducer with a range of 0 to 135 psig. Set SP.XR to 1 for support of a pressure transducer with a range of 0 to 200 psig.

NOTE: The 48/50A2,A3,A4,A5 units do not require a change to the SP.XR factory default setting.

Refrigerant Type (RFG.T) — This configuration specifies the type of refrigerant used in the unit. Configuration RFG.T is set to 0 if the refrigerant used is

Condenser Type (CND.T) — This configuration specifies the type of condenser installed in the unit. Configuration CND.T is set to 0 if the condenser is a round tube, plate fin coil (RTPF). Configuration CND.T is set to 1 if the condenser is a micro- channel heat exchanger coil (MCHX).

MAT Calc Config (MAT.S) — This configuration gives the user three options in the processing of the

•MAT.S = 0

There will be no MAT calculation.

•MAT.S = 1

The control will attempt to learn MAT over time. Any time the system is in a vent mode and the economizer stays at a particular position for long enough, MAT is set to equal EDT. Using this, the control has an internal table whereby it can more closely determine the true MAT value.

•MAT.S = 2

The control will not attempt to learn MAT over time.

To calculate MAT linearly, the user should reset the MAT table entries by setting MAT.R to YES. Then set MAT.S = 2. The control will calculate MAT based on the position of the economizer,

To freeze the MAT table entries, let the unit run with MAT.S

=1. Once sufficient data has been collected, change MAT.S

=2. Do not reset the MAT table.

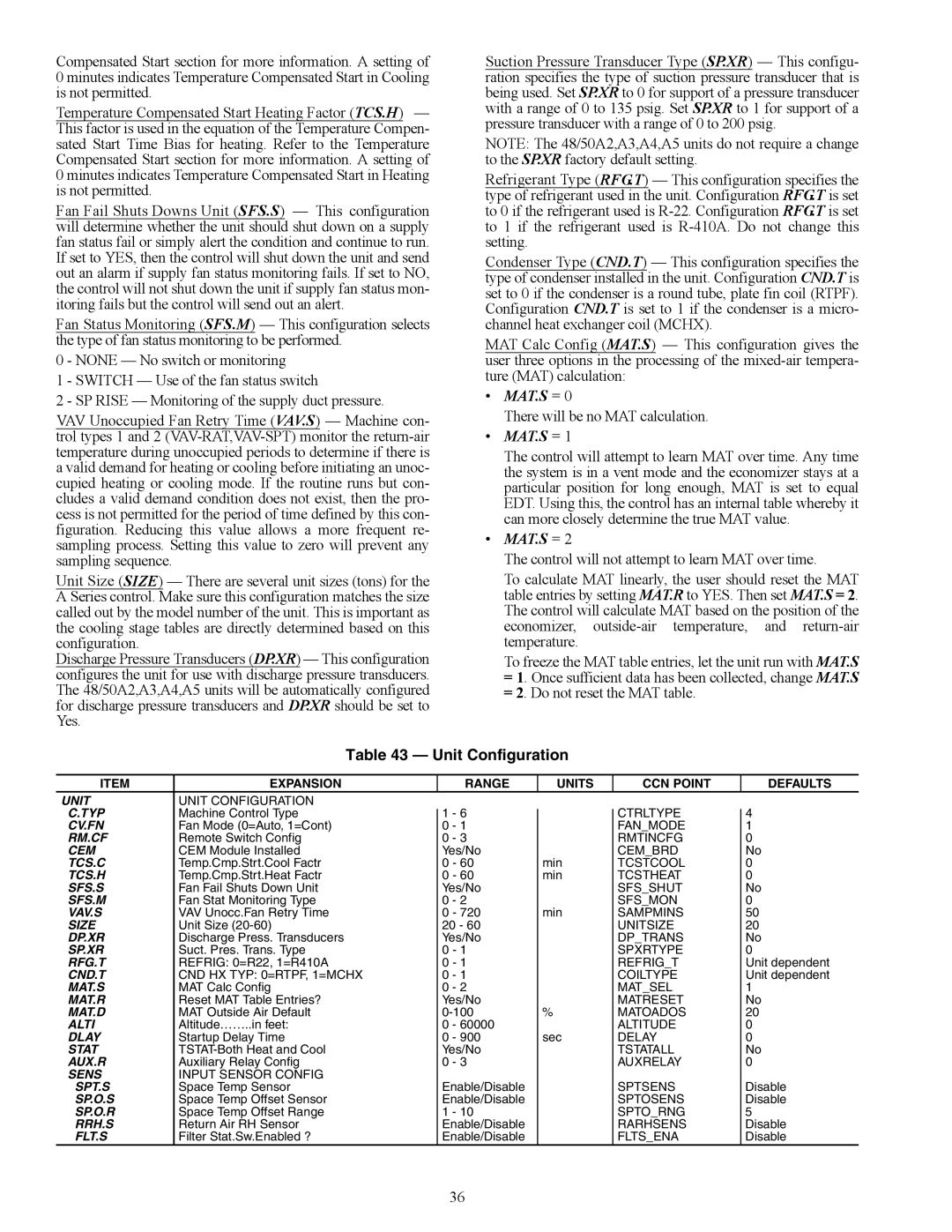

Table 43 — Unit Configuration

ITEM | EXPANSION |

|

| RANGE | UNITS | CCN POINT |

| DEFAULTS |

UNIT | UNIT CONFIGURATION |

|

|

|

|

|

|

|

C.TYP | Machine Control Type |

| 1 | - 6 |

| CTRLTYPE |

| 4 |

|

|

| ||||||

CV.FN | Fan Mode (0=Auto, 1=Cont) |

| 0 | - 1 |

| FAN_MODE |

| 1 |

RM.CF | Remote Switch Config |

| 0 | - 3 |

| RMTINCFG |

| 0 |

CEM | CEM Module Installed |

| Yes/No |

| CEM_BRD |

| No | |

TCS.C | Temp.Cmp.Strt.Cool Factr |

| 0 | - 60 | min | TCSTCOOL |

| 0 |

TCS.H | Temp.Cmp.Strt.Heat Factr |

| 0 | - 60 | min | TCSTHEAT |

| 0 |

SFS.S | Fan Fail Shuts Down Unit |

| Yes/No |

| SFS_SHUT |

| No | |

SFS.M | Fan Stat Monitoring Type |

| 0 | - 2 |

| SFS_MON |

| 0 |

VAV.S | VAV Unocc.Fan Retry Time |

| 0 | - 720 | min | SAMPMINS |

| 50 |

SIZE | Unit Size |

| 20 - 60 |

| UNITSIZE |

| 20 | |

DP.XR | Discharge Press. Transducers |

| Yes/No |

| DP_TRANS |

| No | |

SP.XR | Suct. Pres. Trans. Type |

| 0 | - 1 |

| SPXRTYPE |

| 0 |

RFG.T | REFRIG: 0=R22, 1=R410A |

| 0 | - 1 |

| REFRIG_T |

| Unit dependent |

CND.T | CND HX TYP: 0=RTPF, 1=MCHX |

| 0 | - 1 |

| COILTYPE |

| Unit dependent |

MAT.S | MAT Calc Config |

| 0 | - 2 |

| MAT_SEL |

| 1 |

MAT.R | Reset MAT Table Entries? |

| Yes/No |

| MATRESET |

| No | |

MAT.D | MAT Outside Air Default |

| % | MATOADOS |

| 20 | ||

ALTI | Altitude……..in feet: |

| 0 | - 60000 |

| ALTITUDE |

| 0 |

DLAY | Startup Delay Time |

| 0 | - 900 | sec | DELAY |

| 0 |

STAT |

| Yes/No |

| TSTATALL |

| No | ||

AUX.R | Auxiliary Relay Config |

| 0 | - 3 |

| AUXRELAY |

| 0 |

SENS | INPUT SENSOR CONFIG |

|

|

|

|

|

|

|

SPT.S | Space Temp Sensor |

| Enable/Disable |

| SPTSENS |

| Disable | |

SP.O.S | Space Temp Offset Sensor |

| Enable/Disable |

| SPTOSENS |

| Disable | |

SP.O.R | Space Temp Offset Range |

| 1 | - 10 |

| SPTO_RNG |

| 5 |

RRH.S | Return Air RH Sensor |

| Enable/Disable |

| RARHSENS |

| Disable | |

FLT.S | Filter Stat.Sw.Enabled ? |

| Enable/Disable |

| FLTS_ENA |

| Disable | |

36