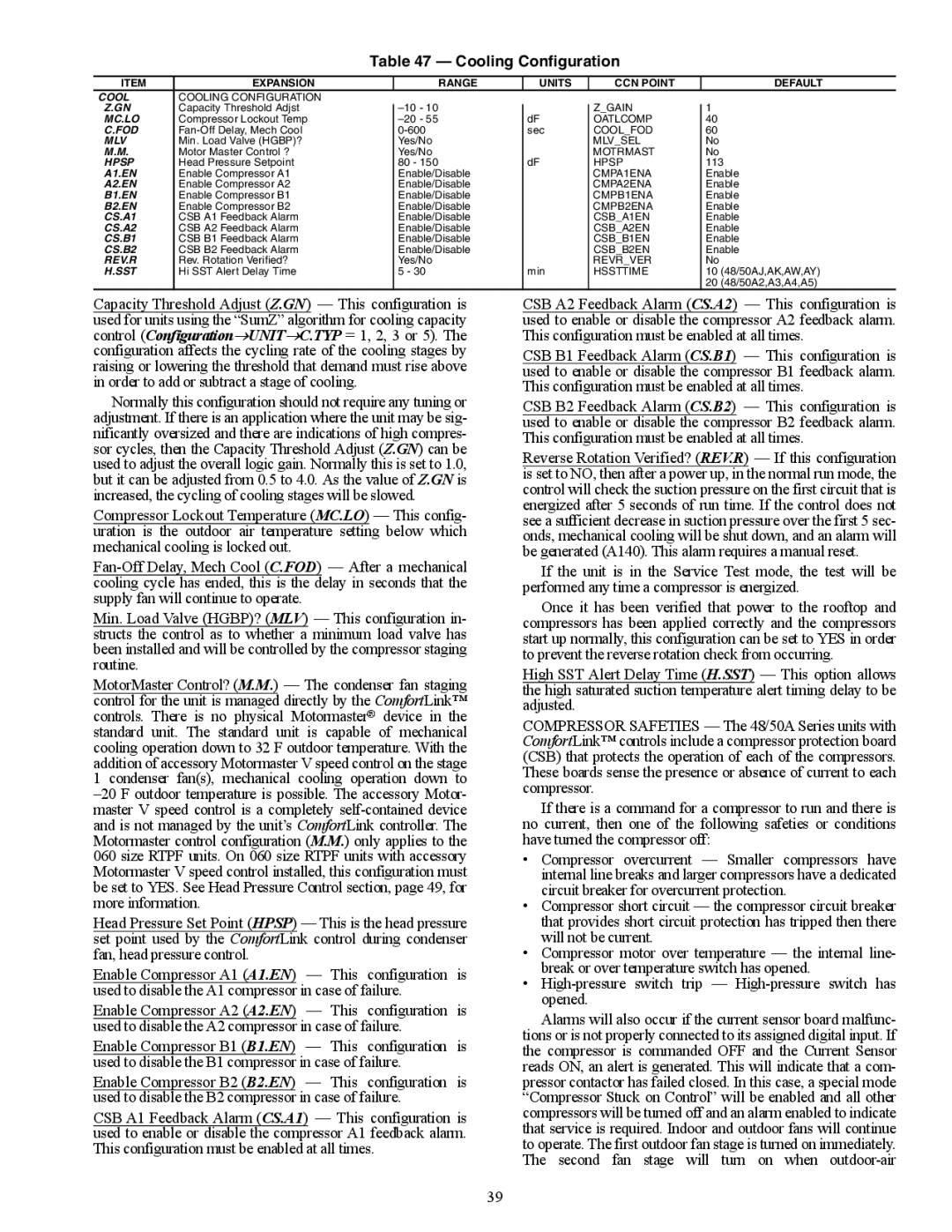

Table 47 — Cooling Configuration

ITEM | EXPANSION |

| RANGE | UNITS | CCN POINT |

| DEFAULT |

COOL | COOLING CONFIGURATION |

|

|

|

|

|

|

Z.GN | Capacity Threshold Adjst |

|

| Z_GAIN |

| 1 | |

|

|

| |||||

MC.LO | Compressor Lockout Temp |

| dF | OATLCOMP |

| 40 | |

C.FOD |

| sec | COOL_FOD |

| 60 | ||

MLV | Min. Load Valve (HGBP)? |

| Yes/No |

| MLV_SEL |

| No |

M.M. | Motor Master Control ? |

| Yes/No |

| MOTRMAST |

| No |

HPSP | Head Pressure Setpoint |

| 80 - 150 | dF | HPSP |

| 113 |

A1.EN | Enable Compressor A1 |

| Enable/Disable |

| CMPA1ENA |

| Enable |

A2.EN | Enable Compressor A2 |

| Enable/Disable |

| CMPA2ENA |

| Enable |

B1.EN | Enable Compressor B1 |

| Enable/Disable |

| CMPB1ENA |

| Enable |

B2.EN | Enable Compressor B2 |

| Enable/Disable |

| CMPB2ENA |

| Enable |

CS.A1 | CSB A1 Feedback Alarm |

| Enable/Disable |

| CSB_A1EN |

| Enable |

CS.A2 | CSB A2 Feedback Alarm |

| Enable/Disable |

| CSB_A2EN |

| Enable |

CS.B1 | CSB B1 Feedback Alarm |

| Enable/Disable |

| CSB_B1EN |

| Enable |

CS.B2 | CSB B2 Feedback Alarm |

| Enable/Disable |

| CSB_B2EN |

| Enable |

REV.R | Rev. Rotation Verified? |

| Yes/No |

| REVR_VER |

| No |

H.SST | Hi SST Alert Delay Time |

| 5 - 30 | min | HSSTTIME |

| 10 (48/50AJ,AK,AW,AY) |

|

|

|

|

|

|

| 20 (48/50A2,A3,A4,A5) |

Capacity Threshold Adjust (Z.GN) — This configuration is used for units using the “SumZ” algorithm for cooling capacity control (Configuration→UNIT→C.TYP = 1, 2, 3 or 5). The configuration affects the cycling rate of the cooling stages by raising or lowering the threshold that demand must rise above in order to add or subtract a stage of cooling.

Normally this configuration should not require any tuning or adjustment. If there is an application where the unit may be sig- nificantly oversized and there are indications of high compres- sor cycles, then the Capacity Threshold Adjust (Z.GN) can be used to adjust the overall logic gain. Normally this is set to 1.0, but it can be adjusted from 0.5 to 4.0. As the value of Z.GN is increased, the cycling of cooling stages will be slowed.

Compressor Lockout Temperature (MC.LO) — This config- uration is the outdoor air temperature setting below which mechanical cooling is locked out.

Min. Load Valve (HGBP)? (MLV) — This configuration in- structs the control as to whether a minimum load valve has been installed and will be controlled by the compressor staging routine.

MotorMaster Control? (M.M.) — The condenser fan staging control for the unit is managed directly by the ComfortLink™ controls. There is no physical Motormaster® device in the standard unit. The standard unit is capable of mechanical cooling operation down to 32 F outdoor temperature. With the addition of accessory Motormaster V speed control on the stage 1 condenser fan(s), mechanical cooling operation down to

Head Pressure Set Point (HPSP) — This is the head pressure set point used by the ComfortLink control during condenser fan, head pressure control.

Enable Compressor A1 (A1.EN) — This configuration is used to disable the A1 compressor in case of failure.

Enable Compressor A2 (A2.EN) — This configuration is used to disable the A2 compressor in case of failure.

Enable Compressor B1 (B1.EN) — This configuration is used to disable the B1 compressor in case of failure.

Enable Compressor B2 (B2.EN) — This configuration is used to disable the B2 compressor in case of failure.

CSB A1 Feedback Alarm (CS.A1) — This configuration is used to enable or disable the compressor A1 feedback alarm. This configuration must be enabled at all times.

CSB A2 Feedback Alarm (CS.A2) — This configuration is used to enable or disable the compressor A2 feedback alarm. This configuration must be enabled at all times.

CSB B1 Feedback Alarm (CS.B1) — This configuration is used to enable or disable the compressor B1 feedback alarm. This configuration must be enabled at all times.

CSB B2 Feedback Alarm (CS.B2) — This configuration is used to enable or disable the compressor B2 feedback alarm. This configuration must be enabled at all times.

Reverse Rotation Verified? (REV.R) — If this configuration is set to NO, then after a power up, in the normal run mode, the control will check the suction pressure on the first circuit that is energized after 5 seconds of run time. If the control does not see a sufficient decrease in suction pressure over the first 5 sec- onds, mechanical cooling will be shut down, and an alarm will be generated (A140). This alarm requires a manual reset.

If the unit is in the Service Test mode, the test will be performed any time a compressor is energized.

Once it has been verified that power to the rooftop and compressors has been applied correctly and the compressors start up normally, this configuration can be set to YES in order to prevent the reverse rotation check from occurring.

High SST Alert Delay Time (H.SST) — This option allows the high saturated suction temperature alert timing delay to be adjusted.

COMPRESSOR SAFETIES — The 48/50A Series units with ComfortLink™ controls include a compressor protection board (CSB) that protects the operation of each of the compressors. These boards sense the presence or absence of current to each compressor.

If there is a command for a compressor to run and there is no current, then one of the following safeties or conditions have turned the compressor off:

•Compressor overcurrent — Smaller compressors have internal line breaks and larger compressors have a dedicated circuit breaker for overcurrent protection.

•Compressor short circuit — the compressor circuit breaker that provides short circuit protection has tripped then there will not be current.

•Compressor motor over temperature — the internal line- break or over temperature switch has opened.

•

Alarms will also occur if the current sensor board malfunc- tions or is not properly connected to its assigned digital input. If the compressor is commanded OFF and the Current Sensor reads ON, an alert is generated. This will indicate that a com- pressor contactor has failed closed. In this case, a special mode “Compressor Stuck on Control” will be enabled and all other compressors will be turned off and an alarm enabled to indicate that service is required. Indoor and outdoor fans will continue to operate. The first outdoor fan stage is turned on immediately. The second fan stage will turn on when

39