Because the Dirty Air Filter switch can be configured nor- mally opened or closed, the switch might be open or closed. The configuration for this switch input can be found at variable Configuration→SW.LG→SFS.L. Verify that the configura- tion is set correctly. Verify the wiring and filter status switch. The hose should be connected to the low side of the switch. This alert resets automatically. The dirty filter switch is enabled

at Configuration→UNIT→SENS→FLT.S.

A409 (Supply Fan Commanded On, Sensed Off Failure)

A409 (Supply Fan Commanded Off, Sensed On Failure)

T409 (Supply Fan Commanded On, Sensed Off Failure)

T409 (Supply Fan Commanded Off, Sensed On Failure) — Both the alert and the alarm refer to the same failure. The only difference between the alarm and alert is that in the case where the supply fan status configuration to shut down the unit is set to YES (Configuration→UNIT→SFS.S), the alarm will be generated AND the unit will be shut down. It is possible to configure Configuration→UNITS→SFS.M to either a switch or to monitor a

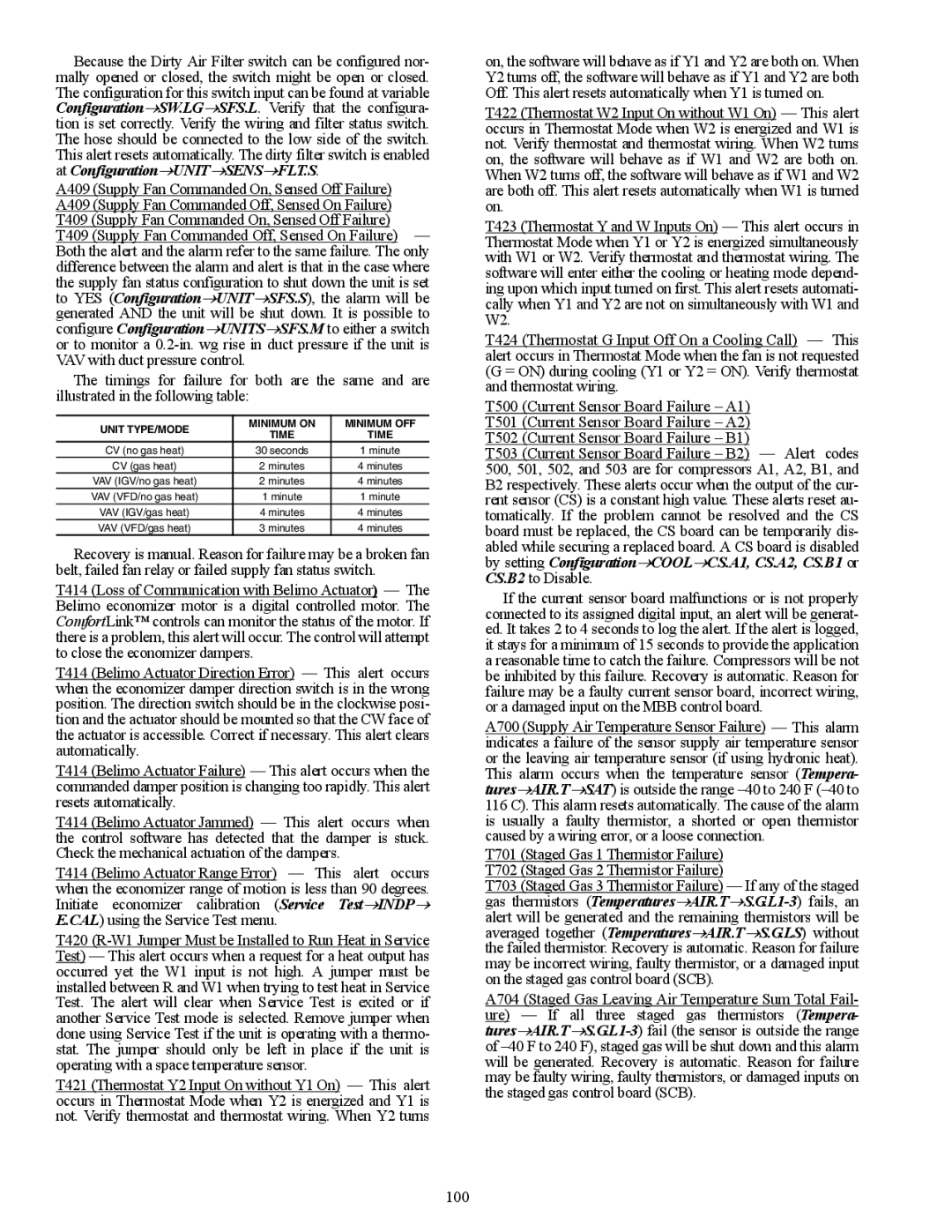

The timings for failure for both are the same and are illustrated in the following table:

UNIT TYPE/MODE | MINIMUM ON | MINIMUM OFF | |

TIME | TIME | ||

| |||

CV (no gas heat) | 30 seconds | 1 minute | |

CV (gas heat) | 2 minutes | 4 minutes | |

VAV (IGV/no gas heat) | 2 minutes | 4 minutes | |

VAV (VFD/no gas heat) | 1 minute | 1 minute | |

VAV (IGV/gas heat) | 4 minutes | 4 minutes | |

VAV (VFD/gas heat) | 3 minutes | 4 minutes |

Recovery is manual. Reason for failure may be a broken fan belt, failed fan relay or failed supply fan status switch.

T414 (Loss of Communication with Belimo Actuator) — The Belimo economizer motor is a digital controlled motor. The ComfortLink™ controls can monitor the status of the motor. If there is a problem, this alert will occur. The control will attempt to close the economizer dampers.

T414 (Belimo Actuator Direction Error) — This alert occurs when the economizer damper direction switch is in the wrong position. The direction switch should be in the clockwise posi- tion and the actuator should be mounted so that the CW face of the actuator is accessible. Correct if necessary. This alert clears automatically.

T414 (Belimo Actuator Failure) — This alert occurs when the commanded damper position is changing too rapidly. This alert resets automatically.

T414 (Belimo Actuator Jammed) — This alert occurs when the control software has detected that the damper is stuck. Check the mechanical actuation of the dampers.

T414 (Belimo Actuator Range Error) — This alert occurs when the economizer range of motion is less than 90 degrees. Initiate economizer calibration (Service Test→INDP→ E.CAL) using the Service Test menu.

T420

T421 (Thermostat Y2 Input On without Y1 On) — This alert occurs in Thermostat Mode when Y2 is energized and Y1 is not. Verify thermostat and thermostat wiring. When Y2 turns

on, the software will behave as if Y1 and Y2 are both on. When Y2 turns off, the software will behave as if Y1 and Y2 are both Off. This alert resets automatically when Y1 is turned on.

T422 (Thermostat W2 Input On without W1 On) — This alert occurs in Thermostat Mode when W2 is energized and W1 is not. Verify thermostat and thermostat wiring. When W2 turns on, the software will behave as if W1 and W2 are both on. When W2 turns off, the software will behave as if W1 and W2 are both off. This alert resets automatically when W1 is turned on.

T423 (Thermostat Y and W Inputs On) — This alert occurs in Thermostat Mode when Y1 or Y2 is energized simultaneously with W1 or W2. Verify thermostat and thermostat wiring. The software will enter either the cooling or heating mode depend- ing upon which input turned on first. This alert resets automati- cally when Y1 and Y2 are not on simultaneously with W1 and W2.

T424 (Thermostat G Input Off On a Cooling Call) — This alert occurs in Thermostat Mode when the fan is not requested (G = ON) during cooling (Y1 or Y2 = ON). Verify thermostat and thermostat wiring.

T500 (Current Sensor Board Failure – A1)

T501 (Current Sensor Board Failure – A2)

T502 (Current Sensor Board Failure – B1)

T503 (Current Sensor Board Failure – B2) — Alert codes 500, 501, 502, and 503 are for compressors A1, A2, B1, and B2 respectively. These alerts occur when the output of the cur- rent sensor (CS) is a constant high value. These alerts reset au- tomatically. If the problem cannot be resolved and the CS board must be replaced, the CS board can be temporarily dis- abled while securing a replaced board. A CS board is disabled by setting Configuration→COOL→CS.A1, CS.A2, CS.B1 or CS.B2 to Disable.

If the current sensor board malfunctions or is not properly connected to its assigned digital input, an alert will be generat- ed. It takes 2 to 4 seconds to log the alert. If the alert is logged, it stays for a minimum of 15 seconds to provide the application a reasonable time to catch the failure. Compressors will be not be inhibited by this failure. Recovery is automatic. Reason for failure may be a faulty current sensor board, incorrect wiring, or a damaged input on the MBB control board.

A700 (Supply Air Temperature Sensor Failure) — This alarm indicates a failure of the sensor supply air temperature sensor or the leaving air temperature sensor (if using hydronic heat). This alarm occurs when the temperature sensor (Tempera- tures→AIR.T→SAT) is outside the range

T701 (Staged Gas 1 Thermistor Failure)

T702 (Staged Gas 2 Thermistor Failure)

T703 (Staged Gas 3 Thermistor Failure) — If any of the staged gas thermistors

A704 (Staged Gas Leaving Air Temperature Sum Total Fail- ure) — If all three staged gas thermistors (Tempera-

100