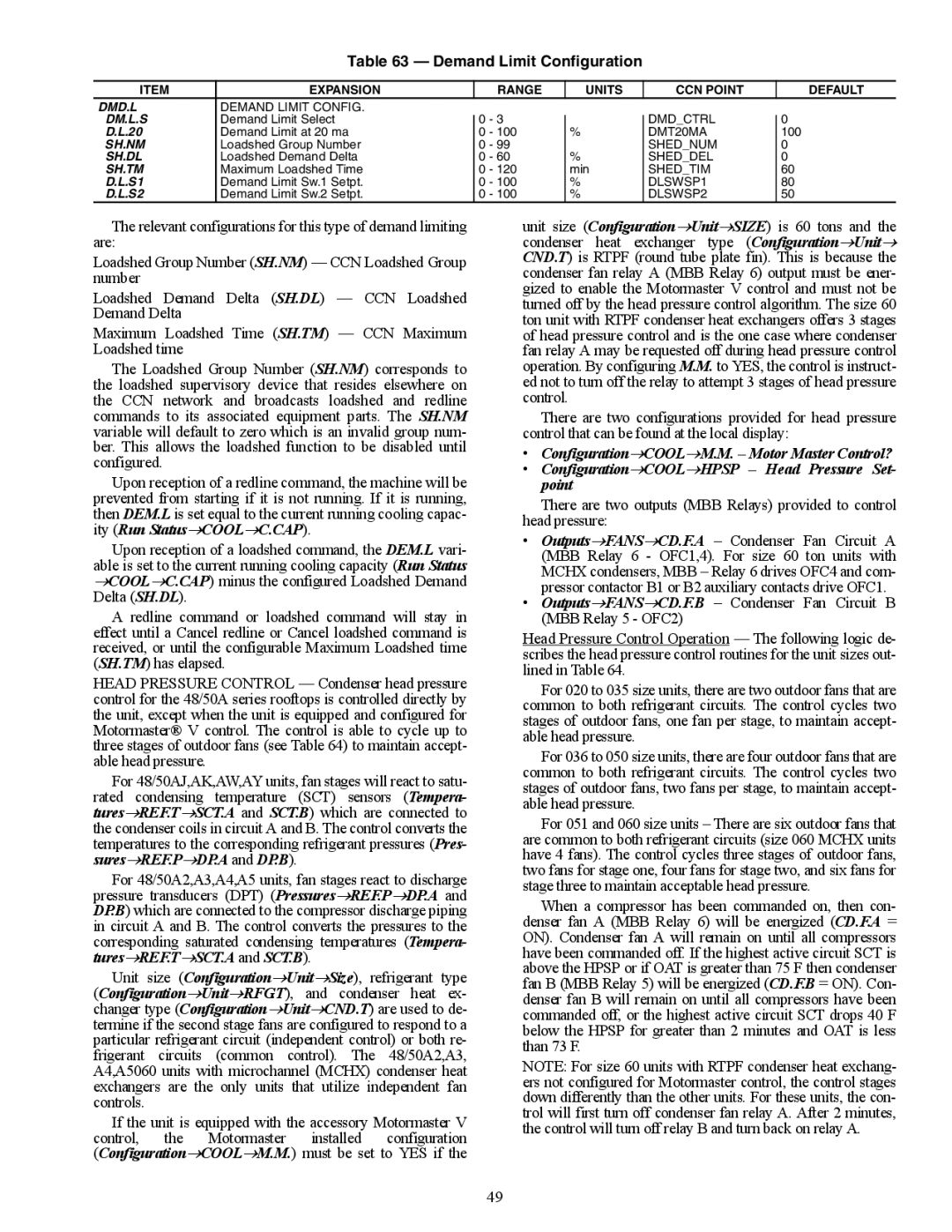

Table 63 — Demand Limit Configuration

ITEM | EXPANSION |

|

| RANGE | UNITS | CCN POINT |

| DEFAULT |

DMD.L | DEMAND LIMIT CONFIG. |

|

|

|

|

|

|

|

DM.L.S | Demand Limit Select |

| 0 | - 3 |

| DMD_CTRL |

| 0 |

|

|

| ||||||

D.L.20 | Demand Limit at 20 ma |

| 0 | - 100 | % | DMT20MA |

| 100 |

SH.NM | Loadshed Group Number |

| 0 | - 99 |

| SHED_NUM |

| 0 |

SH.DL | Loadshed Demand Delta |

| 0 | - 60 | % | SHED_DEL |

| 0 |

SH.TM | Maximum Loadshed Time |

| 0 | - 120 | min | SHED_TIM |

| 60 |

D.L.S1 | Demand Limit Sw.1 Setpt. |

| 0 | - 100 | % | DLSWSP1 |

| 80 |

D.L.S2 | Demand Limit Sw.2 Setpt. |

| 0 | - 100 | % | DLSWSP2 |

| 50 |

The relevant configurations for this type of demand limiting are:

Loadshed Group Number (SH.NM) — CCN Loadshed Group number

Loadshed Demand Delta (SH.DL) — CCN Loadshed Demand Delta

Maximum Loadshed Time (SH.TM) — CCN Maximum Loadshed time

The Loadshed Group Number (SH.NM) corresponds to the loadshed supervisory device that resides elsewhere on the CCN network and broadcasts loadshed and redline commands to its associated equipment parts. The SH.NM variable will default to zero which is an invalid group num- ber. This allows the loadshed function to be disabled until configured.

Upon reception of a redline command, the machine will be prevented from starting if it is not running. If it is running, then DEM.L is set equal to the current running cooling capac- ity (Run Status→COOL→C.CAP).

Upon reception of a loadshed command, the DEM.L vari- able is set to the current running cooling capacity (Run Status →COOL→C.CAP) minus the configured Loadshed Demand Delta (SH.DL).

A redline command or loadshed command will stay in effect until a Cancel redline or Cancel loadshed command is received, or until the configurable Maximum Loadshed time (SH.TM) has elapsed.

HEAD PRESSURE CONTROL — Condenser head pressure control for the 48/50A series rooftops is controlled directly by the unit, except when the unit is equipped and configured for Motormaster® V control. The control is able to cycle up to three stages of outdoor fans (see Table 64) to maintain accept- able head pressure.

For 48/50AJ,AK,AW,AY units, fan stages will react to satu- rated condensing temperature (SCT) sensors (Tempera- tures→REF.T→SCT.A and SCT.B) which are connected to the condenser coils in circuit A and B. The control converts the temperatures to the corresponding refrigerant pressures (Pres- sures→REF.P→DP.A and DP.B).

For 48/50A2,A3,A4,A5 units, fan stages react to discharge pressure transducers (DPT) (Pressures→REF.P→DP.A and DP.B) which are connected to the compressor discharge piping in circuit A and B. The control converts the pressures to the corresponding saturated condensing temperatures (Tempera- tures→REF.T→SCT.A and SCT.B).

Unit size (Configuration→Unit→Size), refrigerant type (Configuration→Unit→RFG.T), and condenser heat ex- changer type (Configuration→Unit→CND.T) are used to de- termine if the second stage fans are configured to respond to a particular refrigerant circuit (independent control) or both re- frigerant circuits (common control). The 48/50A2,A3, A4,A5060 units with microchannel (MCHX) condenser heat exchangers are the only units that utilize independent fan controls.

If the unit is equipped with the accessory Motormaster V control, the Motormaster installed configuration (Configuration→COOL→M.M.) must be set to YES if the

unit size (Configuration→Unit→SIZE) is 60 tons and the condenser heat exchanger type (Configuration→Unit→ CND.T) is RTPF (round tube plate fin). This is because the condenser fan relay A (MBB Relay 6) output must be ener- gized to enable the Motormaster V control and must not be turned off by the head pressure control algorithm. The size 60 ton unit with RTPF condenser heat exchangers offers 3 stages of head pressure control and is the one case where condenser fan relay A may be requested off during head pressure control operation. By configuring M.M. to YES, the control is instruct- ed not to turn off the relay to attempt 3 stages of head pressure control.

There are two configurations provided for head pressure control that can be found at the local display:

•Configuration→COOL→M.M. – Motor Master Control?

•Configuration→COOL→HPSP – Head Pressure Set- point

There are two outputs (MBB Relays) provided to control head pressure:

•Outputs→FANS→CD.F.A – Condenser Fan Circuit A (MBB Relay 6 - OFC1,4). For size 60 ton units with MCHX condensers, MBB – Relay 6 drives OFC4 and com- pressor contactor B1 or B2 auxiliary contacts drive OFC1.

•Outputs→FANS→CD.F.B – Condenser Fan Circuit B (MBB Relay 5 - OFC2)

Head Pressure Control Operation — The following logic de- scribes the head pressure control routines for the unit sizes out- lined in Table 64.

For 020 to 035 size units, there are two outdoor fans that are common to both refrigerant circuits. The control cycles two stages of outdoor fans, one fan per stage, to maintain accept- able head pressure.

For 036 to 050 size units, there are four outdoor fans that are common to both refrigerant circuits. The control cycles two stages of outdoor fans, two fans per stage, to maintain accept- able head pressure.

For 051 and 060 size units – There are six outdoor fans that are common to both refrigerant circuits (size 060 MCHX units have 4 fans). The control cycles three stages of outdoor fans, two fans for stage one, four fans for stage two, and six fans for stage three to maintain acceptable head pressure.

When a compressor has been commanded on, then con- denser fan A (MBB Relay 6) will be energized (CD.F.A = ON). Condenser fan A will remain on until all compressors have been commanded off. If the highest active circuit SCT is above the HPSP or if OAT is greater than 75 F then condenser fan B (MBB Relay 5) will be energized (CD.F.B = ON). Con- denser fan B will remain on until all compressors have been commanded off, or the highest active circuit SCT drops 40 F below the HPSP for greater than 2 minutes and OAT is less than 73 F.

NOTE: For size 60 units with RTPF condenser heat exchang- ers not configured for Motormaster control, the control stages down differently than the other units. For these units, the con- trol will first turn off condenser fan relay A. After 2 minutes, the control will turn off relay B and turn back on relay A.

49