opening after the piston rings are compressed. A piston ring compresser will facilitate removal. Each piston pin is locked in place by lock rings which are snapped into grooves in the piston wall.

|

| 6 | 5 |

|

| 7 |

|

| |

|

|

|

| |

9 | 8 |

|

|

|

|

| 3 | 4 | |

|

|

|

| |

|

|

| 2 |

|

10

1

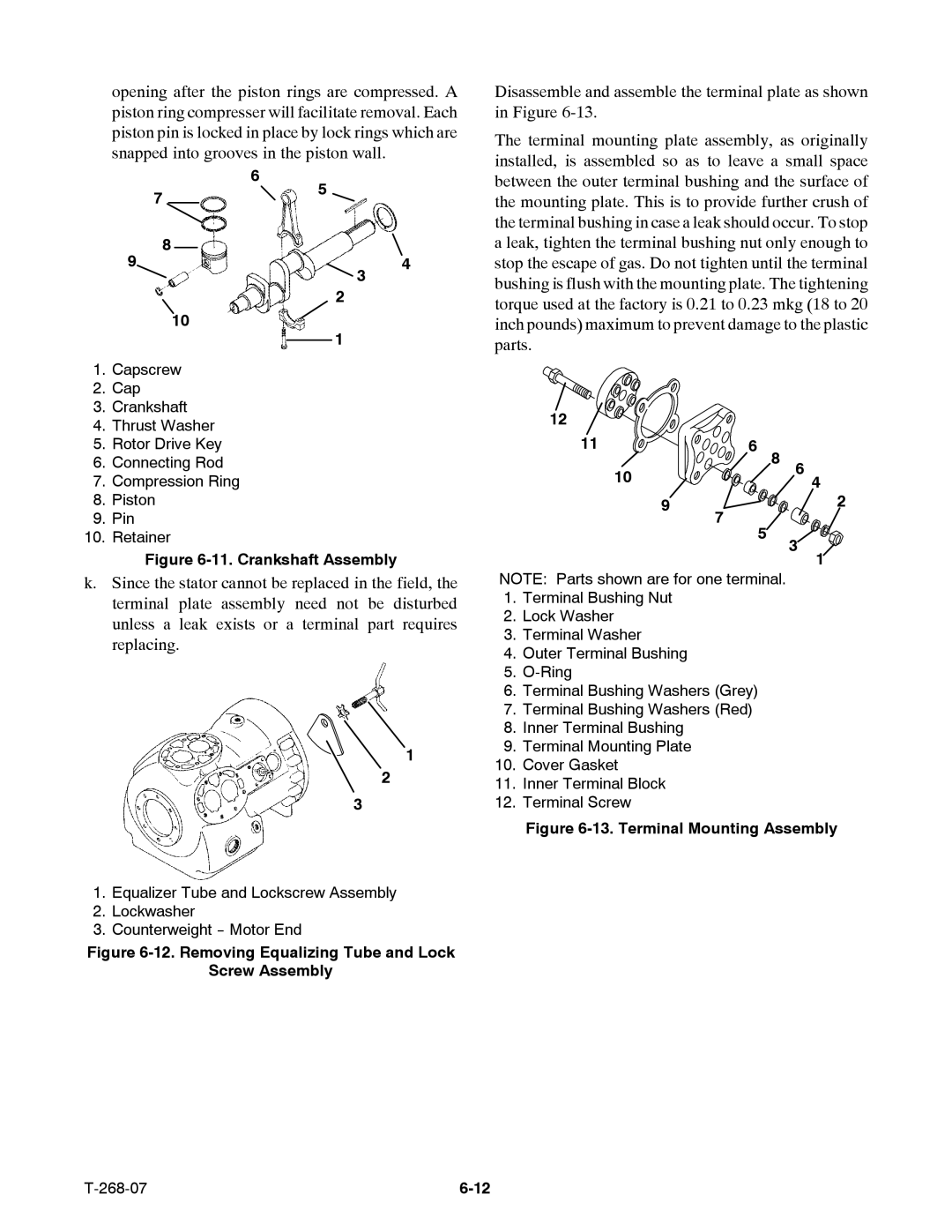

1.Capscrew

2.Cap

3.Crankshaft

4.Thrust Washer

5.Rotor Drive Key

6.Connecting Rod

7.Compression Ring

8.Piston

9.Pin

10.Retainer

Figure 6-11. Crankshaft Assembly

k.Since the stator cannot be replaced in the field, the terminal plate assembly need not be disturbed unless a leak exists or a terminal part requires replacing.

1

2

3

1.Equalizer Tube and Lockscrew Assembly

2.Lockwasher

3.Counterweight

Figure 6-12. Removing Equalizing Tube and Lock

Screw Assembly

Disassemble and assemble the terminal plate as shown in Figure

The terminal mounting plate assembly, as originally installed, is assembled so as to leave a small space between the outer terminal bushing and the surface of the mounting plate. This is to provide further crush of the terminal bushing in case a leak should occur. To stop a leak, tighten the terminal bushing nut only enough to stop the escape of gas. Do not tighten until the terminal bushing is flush with the mounting plate. The tightening torque used at the factory is 0.21 to 0.23 mkg (18 to 20 inch pounds) maximum to prevent damage to the plastic parts.

12

11 |

| 6 | 8 |

|

|

| 10 | 6 | 4 | ||

|

|

|

| ||

|

|

|

|

| |

| 9 | 7 |

|

| 2 |

|

|

|

|

|

5 | 3 |

|

| 1 | |

|

|

NOTE: Parts shown are for one terminal.

1.Terminal Bushing Nut

2.Lock Washer

3.Terminal Washer

4.Outer Terminal Bushing

5.

6.Terminal Bushing Washers (Grey)

7.Terminal Bushing Washers (Red)

8.Inner Terminal Bushing

9.Terminal Mounting Plate

10.Cover Gasket

11.Inner Terminal Block

12.Terminal Screw

Figure 6-13. Terminal Mounting Assembly

|