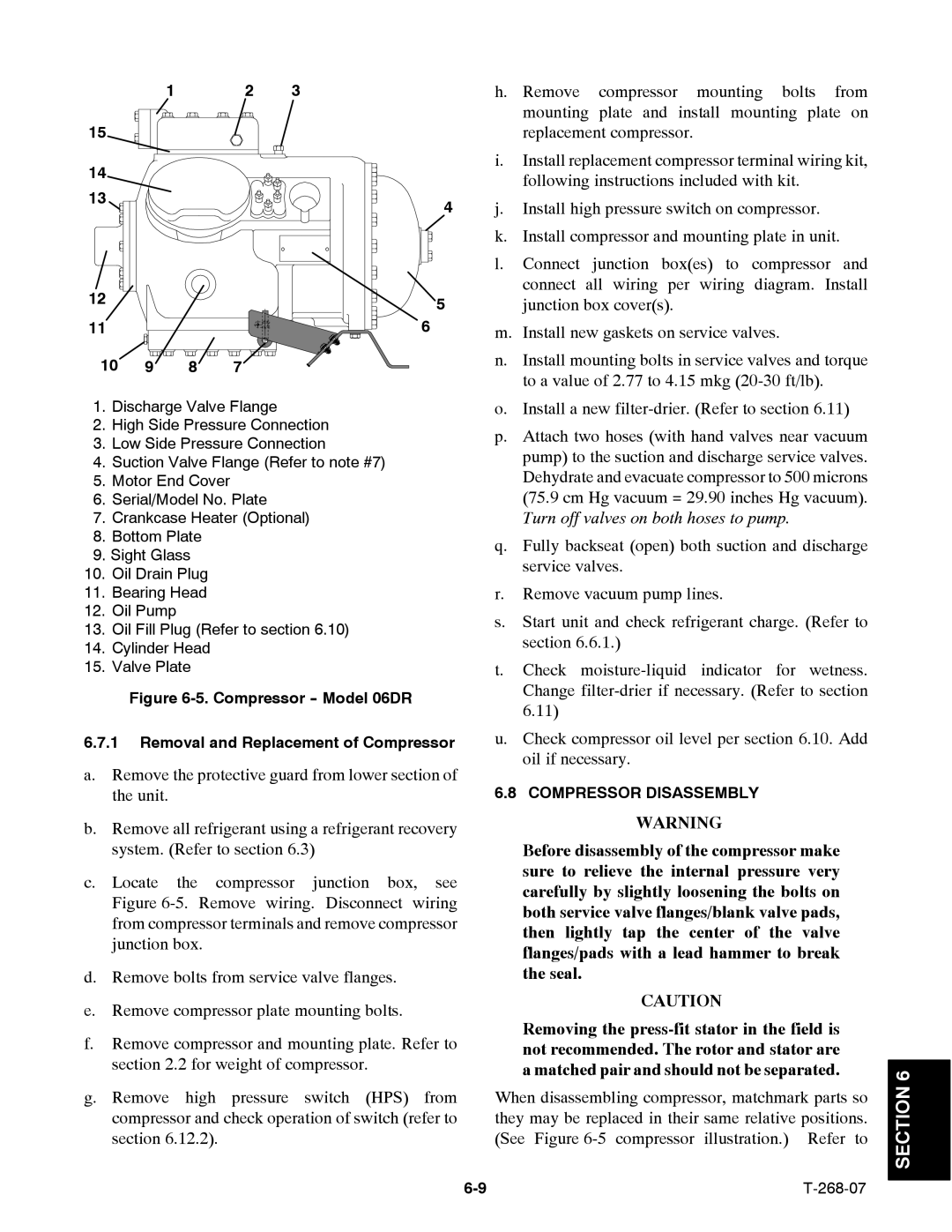

1 2

15

14

13

12

11

10 9 8 7

3

4

5

6

h. Remove compressor mounting bolts from mounting plate and install mounting plate on replacement compressor.

i. | Install replacement compressor terminal wiring kit, |

| following instructions included with kit. |

j. | Install high pressure switch on compressor. |

k. | Install compressor and mounting plate in unit. |

l. | Connect junction box(es) to compressor and |

| connect all wiring per wiring diagram. Install |

| junction box cover(s). |

m. Install new gaskets on service valves. | |

n. | Install mounting bolts in service valves and torque |

| to a value of 2.77 to 4.15 mkg |

1.Discharge Valve Flange

2.High Side Pressure Connection

3.Low Side Pressure Connection

4.Suction Valve Flange (Refer to note #7)

5.Motor End Cover

6.Serial/Model No. Plate

7.Crankcase Heater (Optional)

8.Bottom Plate

9.Sight Glass

10.Oil Drain Plug

11.Bearing Head

12.Oil Pump

13.Oil Fill Plug (Refer to section 6.10)

14.Cylinder Head

15.Valve Plate

Figure 6-5. Compressor -- Model 06DR

6.7.1Removal and Replacement of Compressor

a.Remove the protective guard from lower section of the unit.

b.Remove all refrigerant using a refrigerant recovery system. (Refer to section 6.3)

c.Locate the compressor junction box, see Figure

d.Remove bolts from service valve flanges.

e.Remove compressor plate mounting bolts.

f.Remove compressor and mounting plate. Refer to section 2.2 for weight of compressor.

g.Remove high pressure switch (HPS) from compressor and check operation of switch (refer to section 6.12.2).

o. | Install a new |

p. | Attach two hoses (with hand valves near vacuum |

| pump) to the suction and discharge service valves. |

| Dehydrate and evacuate compressor to 500 microns |

| (75.9 cm Hg vacuum = 29.90 inches Hg vacuum). |

| Turn off valves on both hoses to pump. |

q. | Fully backseat (open) both suction and discharge |

| service valves. |

r. | Remove vacuum pump lines. |

s. | Start unit and check refrigerant charge. (Refer to |

| section 6.6.1.) |

t. | Check |

| Change |

| 6.11) |

u. | Check compressor oil level per section 6.10. Add |

| oil if necessary. |

6.8 COMPRESSOR DISASSEMBLY

WARNING

Before disassembly of the compressor make sure to relieve the internal pressure very carefully by slightly loosening the bolts on both service valve flanges/blank valve pads, then lightly tap the center of the valve flanges/pads with a lead hammer to break the seal.

CAUTION

Removing the

When disassembling compressor, matchmark parts so they may be replaced in their same relative positions. (See Figure