SECTION 3

MICROPROCESSOR

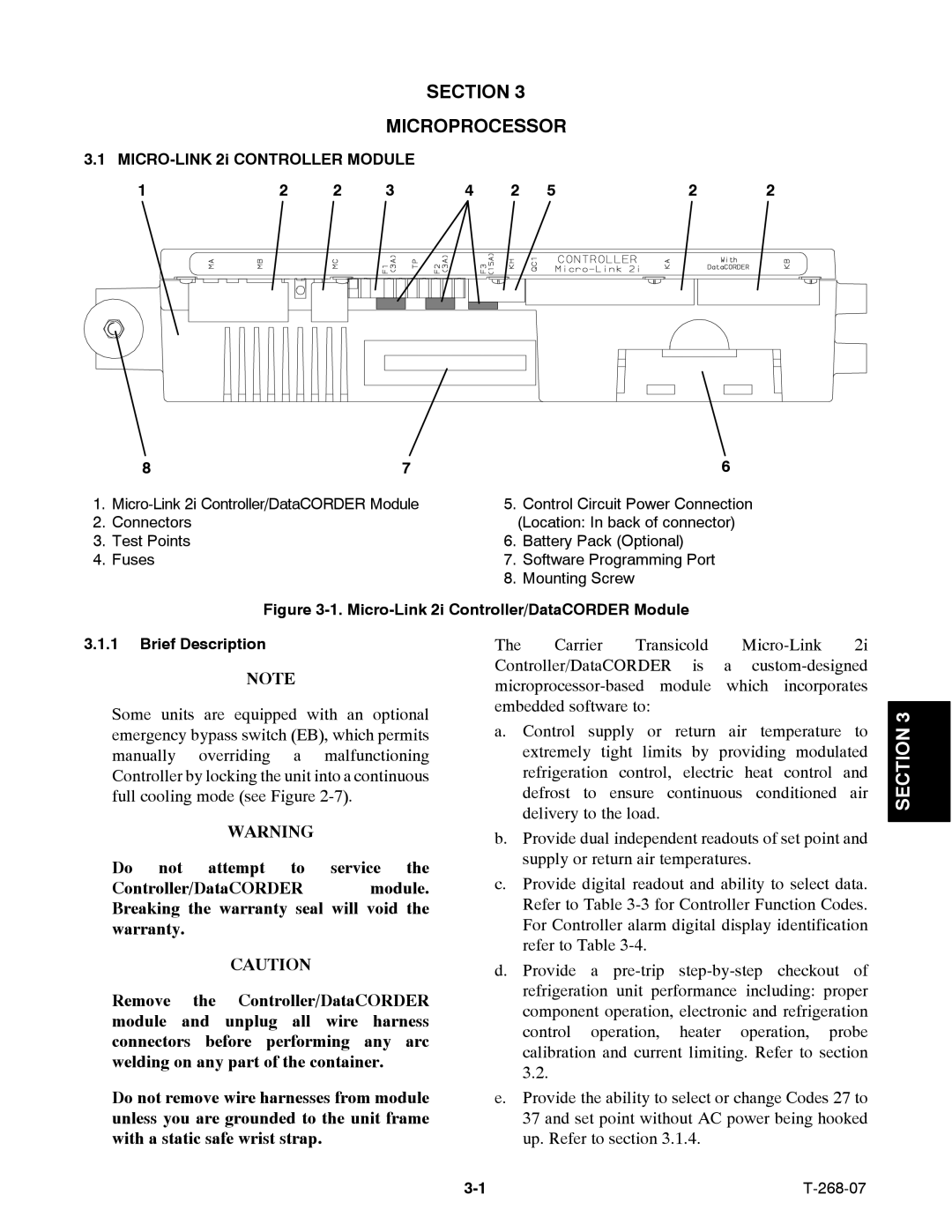

3.1 MICRO-LINK 2i CONTROLLER MODULE

1 | 2 | 2 | 3 | 4 | 2 | 5 | 2 | 2 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 8 | 7 |

| 6 |

1. | 5. | Control Circuit Power Connection | ||

2. | Connectors |

|

| (Location: In back of connector) |

3. | Test Points |

| 6. | Battery Pack (Optional) |

4. | Fuses |

| 7. | Software Programming Port |

|

|

| 8. | Mounting Screw |

Figure 3-1. Micro-Link 2i Controller/DataCORDER Module

3.1.1Brief Description

NOTE

Some units are equipped with an optional emergency bypass switch (EB), which permits manually overriding a malfunctioning Controller by locking the unit into a continuous full cooling mode (see Figure

WARNING

Do not attempt to service the

Controller/DataCORDER module. Breaking the warranty seal will void the warranty.

CAUTION

Remove the Controller/DataCORDER module and unplug all wire harness connectors before performing any arc welding on any part of the container.

The Carrier Transicold

a. Control supply or return air temperature to extremely tight limits by providing modulated refrigeration control, electric heat control and defrost to ensure continuous conditioned air delivery to the load.

b.Provide dual independent readouts of set point and supply or return air temperatures.

c.Provide digital readout and ability to select data. Refer to Table

d.Provide a

SECTION 3

Do not remove wire harnesses from module | e. Provide the ability to select or change Codes 27 to |

unless you are grounded to the unit frame | 37 and set point without AC power being hooked |

with a static safe wrist strap. | up. Refer to section 3.1.4. |