4. If adjustment is required, loosen setscrew | S | Calibration should only be done when bulb | |

| temperature is decreasing. | ||

the adjustment screw clockwise to set the stylus 1 to | S | DO NOT move stylus by hand. | |

2_C (1.8 to 3.6_F) higher than desired temperature. | |||

|

|

5.Rotate the adjustment screw counterclockwise to set the stylus about 0.5_C (0.9_F) higher than set temperature. Rotate the chart by hand. The indicated temperature should be 0_C (32_F).

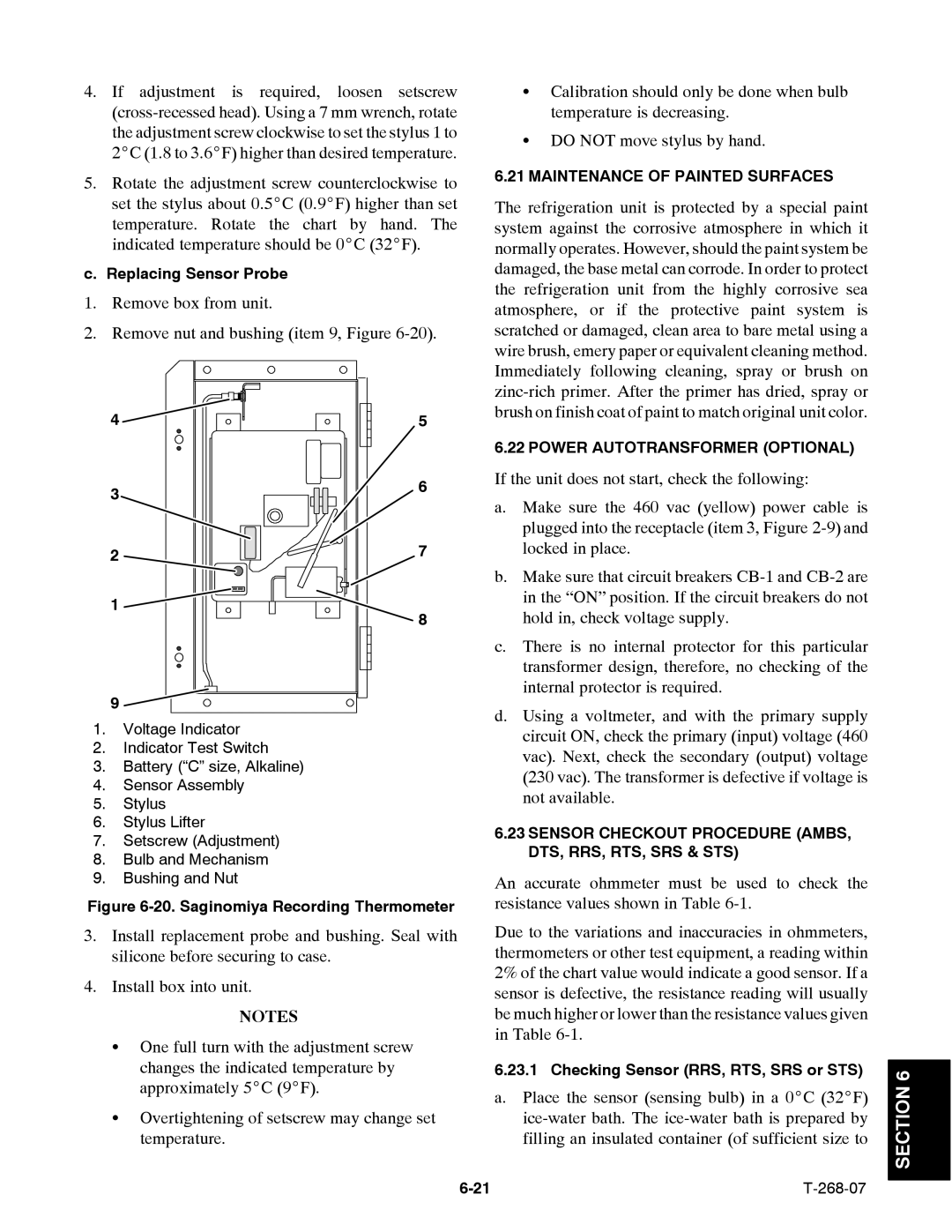

c. Replacing Sensor Probe

1.Remove box from unit.

2.Remove nut and bushing (item 9, Figure 6-20).

4 | 5 |

3 | 6 |

| |

2 | 7 |

1 | 8 |

|

9

1.Voltage Indicator

2.Indicator Test Switch

3.Battery (“C” size, Alkaline)

4.Sensor Assembly

5.Stylus

6.Stylus Lifter

7.Setscrew (Adjustment)

8.Bulb and Mechanism

9.Bushing and Nut

Figure 6-20. Saginomiya Recording Thermometer

3.Install replacement probe and bushing. Seal with silicone before securing to case.

4.Install box into unit.

NOTES

SOne full turn with the adjustment screw changes the indicated temperature by approximately 5_C (9_F).

SOvertightening of setscrew may change set temperature.

6.21 MAINTENANCE OF PAINTED SURFACES

The refrigeration unit is protected by a special paint system against the corrosive atmosphere in which it normally operates. However, should the paint system be damaged, the base metal can corrode. In order to protect the refrigeration unit from the highly corrosive sea atmosphere, or if the protective paint system is scratched or damaged, clean area to bare metal using a wire brush, emery paper or equivalent cleaning method. Immediately following cleaning, spray or brush on

6.22 POWER AUTOTRANSFORMER (OPTIONAL)

If the unit does not start, check the following:

a.Make sure the 460 vac (yellow) power cable is plugged into the receptacle (item 3, Figure

b.Make sure that circuit breakers

c.There is no internal protector for this particular transformer design, therefore, no checking of the internal protector is required.

d.Using a voltmeter, and with the primary supply circuit ON, check the primary (input) voltage (460 vac). Next, check the secondary (output) voltage (230 vac). The transformer is defective if voltage is not available.

6.23SENSOR CHECKOUT PROCEDURE (AMBS, DTS, RRS, RTS, SRS & STS)

An accurate ohmmeter must be used to check the resistance values shown in Table

Due to the variations and inaccuracies in ohmmeters, thermometers or other test equipment, a reading within 2% of the chart value would indicate a good sensor. If a sensor is defective, the resistance reading will usually be much higher or lower than the resistance values given in Table

6.23.1 Checking Sensor (RRS, RTS, SRS or STS)

a.Place the sensor (sensing bulb) in a 0_C (32_F)