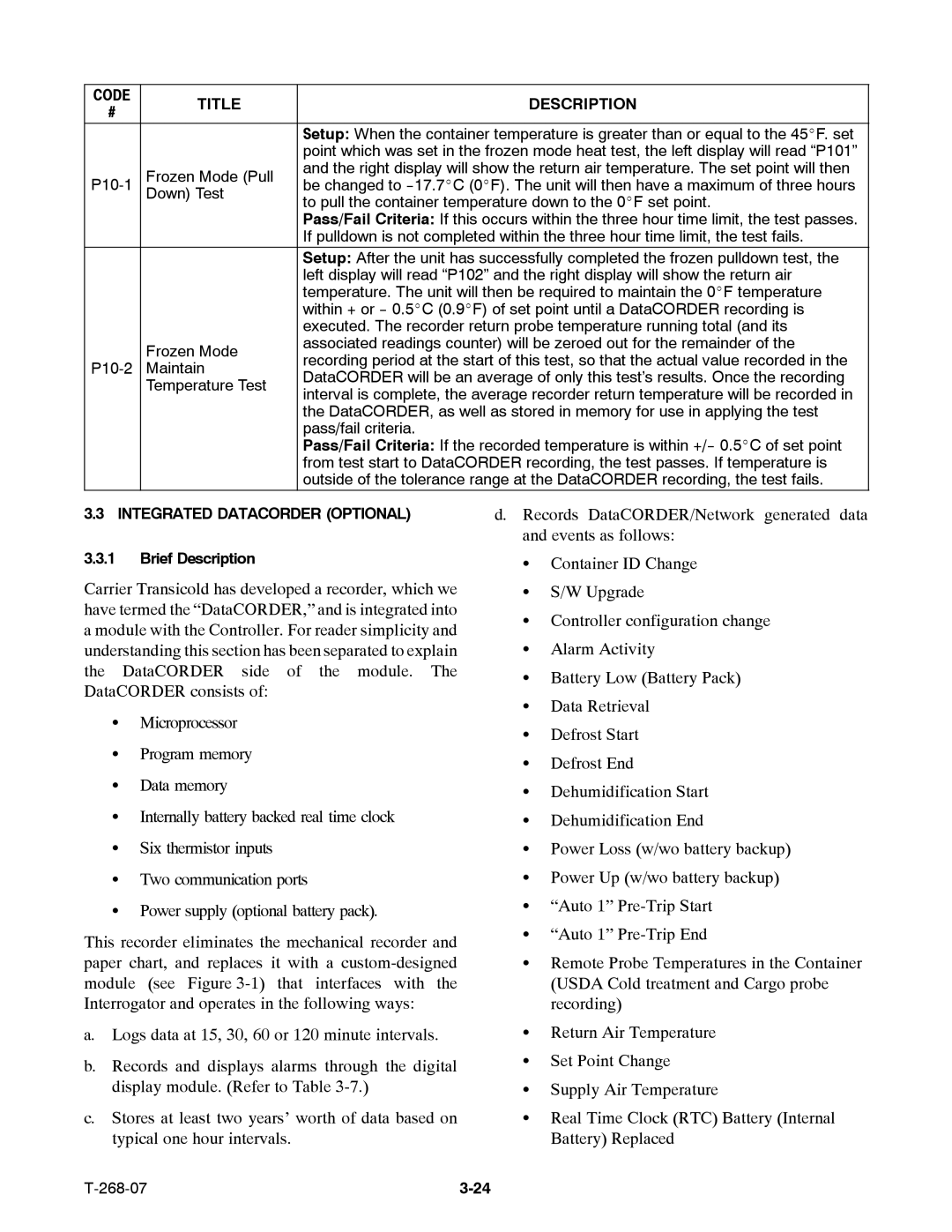

CODE | TITLE | DESCRIPTION | |

# | |||

|

| ||

|

| Setup: When the container temperature is greater than or equal to the 45_F. set | |

|

| point which was set in the frozen mode heat test, the left display will read “P101” | |

Frozen Mode (Pull | and the right display will show the return air temperature. The set point will then | ||

be changed to | |||

| Down) Test | to pull the container temperature down to the 0_F set point. | |

|

| Pass/Fail Criteria: If this occurs within the three hour time limit, the test passes. | |

|

| If pulldown is not completed within the three hour time limit, the test fails. | |

|

| Setup: After the unit has successfully completed the frozen pulldown test, the | |

|

| left display will read “P102” and the right display will show the return air | |

|

| temperature. The unit will then be required to maintain the 0_F temperature | |

|

| within + or | |

|

| executed. The recorder return probe temperature running total (and its | |

| Frozen Mode | associated readings counter) will be zeroed out for the remainder of the | |

| recording period at the start of this test, so that the actual value recorded in the | ||

Maintain | |||

DataCORDER will be an average of only this test’s results. Once the recording | |||

| Temperature Test | ||

| interval is complete, the average recorder return temperature will be recorded in | ||

|

| ||

|

| the DataCORDER, as well as stored in memory for use in applying the test | |

|

| pass/fail criteria. | |

|

| Pass/Fail Criteria: If the recorded temperature is within | |

|

| from test start to DataCORDER recording, the test passes. If temperature is | |

|

| outside of the tolerance range at the DataCORDER recording, the test fails. |

3.3 | INTEGRATED DATACORDER (OPTIONAL) |

| d. Records DataCORDER/Network generated data | |||||

|

|

|

|

|

| and events as follows: | ||

3.3.1 | Brief Description |

|

|

| S | Container ID Change | ||

Carrier Transicold has developed a recorder, which we | S | S/W Upgrade | ||||||

have termed the “DataCORDER,” and is integrated into | S | Controller configuration change | ||||||

a module with the Controller. For reader simplicity and | ||||||||

| Alarm Activity | |||||||

understanding this section has been separated to explain | S | |||||||

the |

| DataCORDER side | of | the module. | The | S | Battery Low (Battery Pack) | |

DataCORDER consists of: |

|

|

| |||||

|

|

| S | Data Retrieval | ||||

| S | Microprocessor |

|

|

| |||

|

|

|

| S | Defrost Start | |||

|

| Program memory |

|

|

| |||

| S |

|

|

| S | Defrost End | ||

|

|

|

|

|

| |||

| S | Data memory |

|

|

| S | Dehumidification Start | |

|

|

|

|

|

| |||

| S Internally battery backed real time clock |

| S | Dehumidification End | ||||

| S | Six thermistor inputs |

|

|

| S | Power Loss (w/wo battery backup) | |

| S | Two communication ports |

|

| S | Power Up (w/wo battery backup) | ||

| S Power supply (optional battery pack). |

| S | “Auto 1” | ||||

This recorder eliminates the mechanical recorder and | S “Auto 1” | |||||||

|

| |||||||

paper chart, and replaces it with a | S | Remote Probe Temperatures in the Container | ||||||

module (see Figure | that | interfaces with | the |

| (USDA Cold treatment and Cargo probe | |||

Interrogator and operates in the following ways: |

|

| recording) | |||||

a. | Logs data at 15, 30, 60 or 120 minute intervals. | S | Return Air Temperature | |||||

b. | Records and displays alarms through the digital | S | Set Point Change | |||||

|

| |||||||

| display module. (Refer to Table |

| S | Supply Air Temperature | ||||

c. | Stores at least two years’ worth of data based on | S | Real Time Clock (RTC) Battery (Internal | |||||

| typical one hour intervals. |

|

|

| Battery) Replaced | |||