14

25

3

6

7

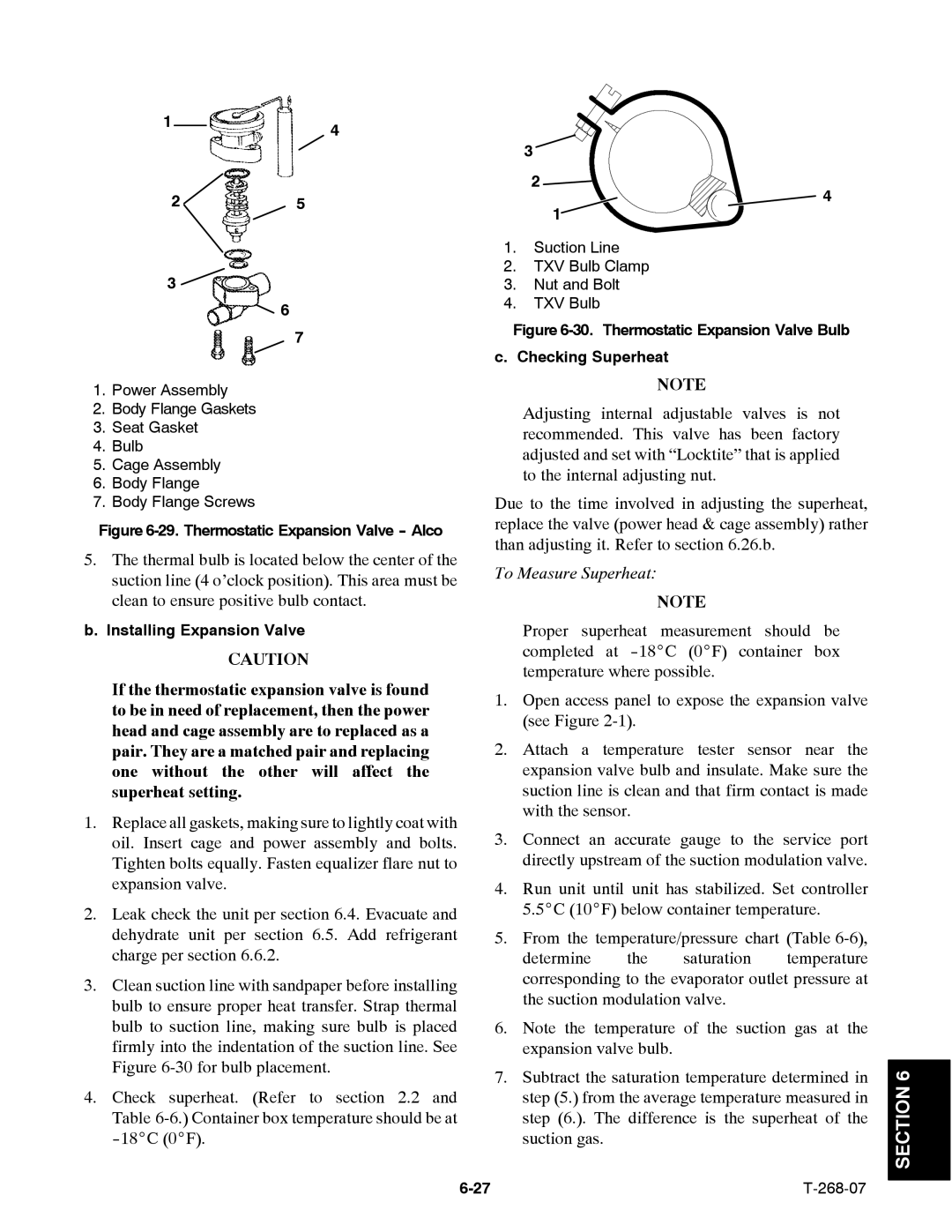

1.Power Assembly

2.Body Flange Gaskets

3.Seat Gasket

4.Bulb

5.Cage Assembly

6.Body Flange

7.Body Flange Screws

Figure 6-29. Thermostatic Expansion Valve -- Alco

5.The thermal bulb is located below the center of the suction line (4 o’clock position). This area must be clean to ensure positive bulb contact.

b.Installing Expansion Valve

CAUTION

If the thermostatic expansion valve is found to be in need of replacement, then the power head and cage assembly are to replaced as a pair. They are a matched pair and replacing one without the other will affect the superheat setting.

1.Replace all gaskets, making sure to lightly coat with oil. Insert cage and power assembly and bolts. Tighten bolts equally. Fasten equalizer flare nut to expansion valve.

2.Leak check the unit per section 6.4. Evacuate and dehydrate unit per section 6.5. Add refrigerant charge per section 6.6.2.

3.Clean suction line with sandpaper before installing bulb to ensure proper heat transfer. Strap thermal bulb to suction line, making sure bulb is placed firmly into the indentation of the suction line. See Figure

4.Check superheat. (Refer to section 2.2 and Table

3

2

4

1

1.Suction Line

2.TXV Bulb Clamp

3.Nut and Bolt

4.TXV Bulb

Figure 6-30. Thermostatic Expansion Valve Bulb

c.Checking Superheat

NOTE

Adjusting internal adjustable valves is not recommended. This valve has been factory adjusted and set with “Locktite” that is applied to the internal adjusting nut.

Due to the time involved in adjusting the superheat, replace the valve (power head & cage assembly) rather than adjusting it. Refer to section 6.26.b.

To Measure Superheat:

NOTE

Proper superheat measurement should be completed at

1.Open access panel to expose the expansion valve (see Figure

2.Attach a temperature tester sensor near the expansion valve bulb and insulate. Make sure the suction line is clean and that firm contact is made with the sensor.

3.Connect an accurate gauge to the service port directly upstream of the suction modulation valve.

4.Run unit until unit has stabilized. Set controller 5.5_C (10_F) below container temperature.

5.From the temperature/pressure chart (Table

6.Note the temperature of the suction gas at the expansion valve bulb.

7.Subtract the saturation temperature determined in step (5.) from the average temperature measured in step (6.). The difference is the superheat of the suction gas.