Start, Power Outages, and Temperature

3.3.10 DataCORDER Scrollback

The DataCORDER will display probe values for the six DataCORDER probes up to 99 hours back from the current hour. The probe values may be displayed by depressing the ALT. MODE key and then depressing the UP or DOWN ARROW keys until “dCdSP” is shown in the left display window and then depressing the ENTER key. The sensor to display can then be chosen by depressing the UP or DOWN ARROW key until the desired sensor (S for supply, r for return, P1, P2, P3 and C4 for USDA and Cargo probes) is shown in the left display window and then depressing the ENTER key. A temperature value will appear in the right display window and 1 (with sensor designation) will appear in the left display window to signify the temperature displayed is the most recent reading. Each press of the DOWN ARROW key displays the temperature one hour earlier. Use the ENTER key to alternate between sensors and times/temperatures. Use the ARROW keys for scrolling. The display will return to normal if 15 seconds lapse without a key being pressed.

3.4 USDA COLD TREATMENT PROCEDURE

Sustained cold temperature has been employed as an effective postharvest method for the control of Mediterranean and certain other tropical fruit flies. Exposing infested fruit to temperatures of 2.2 degrees Celsius (36_F) or below for specific periods results in the mortality of the various stages of this group of notoriously injurious insects.

In response to the demand to replace fumigation with this environmentally sound process, Carrier has integrated this Cold Treatment capability into its DataCORDER. These units have the ability to maintain supply air temperature within

The following is a summary of the steps required to initiate a USDA Cold Treatment.

a.

b.

c.Install the DataCORDER module battery pack (if not already installed).

d.Calibrate the three USDA probes by ice bathing the probes and performing the calibration function with the hand held DataReader or a

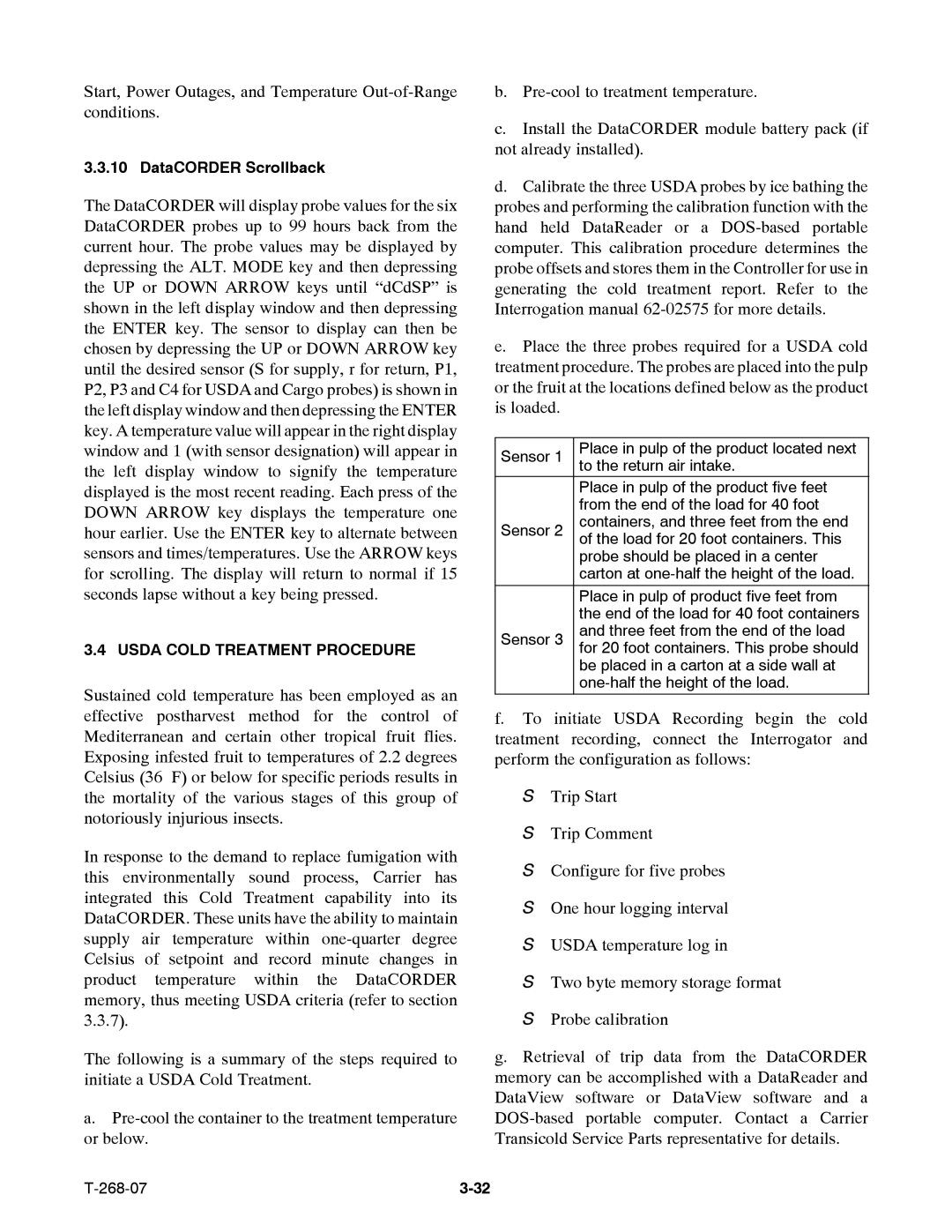

e.Place the three probes required for a USDA cold treatment procedure. The probes are placed into the pulp or the fruit at the locations defined below as the product is loaded.

Sensor 1 | Place in pulp of the product located next |

| to the return air intake. |

| Place in pulp of the product five feet |

| from the end of the load for 40 foot |

Sensor 2 | containers, and three feet from the end |

of the load for 20 foot containers. This | |

| probe should be placed in a center |

| carton at |

| Place in pulp of product five feet from |

| the end of the load for 40 foot containers |

Sensor 3 | and three feet from the end of the load |

for 20 foot containers. This probe should | |

| be placed in a carton at a side wall at |

|

f.To initiate USDA Recording begin the cold treatment recording, connect the Interrogator and perform the configuration as follows:

STrip Start

STrip Comment

SConfigure for five probes

SOne hour logging interval

SUSDA temperature log in

STwo byte memory storage format

SProbe calibration

g. Retrieval of trip data from the DataCORDER memory can be accomplished with a DataReader and DataView software or DataView software and a